Industry news

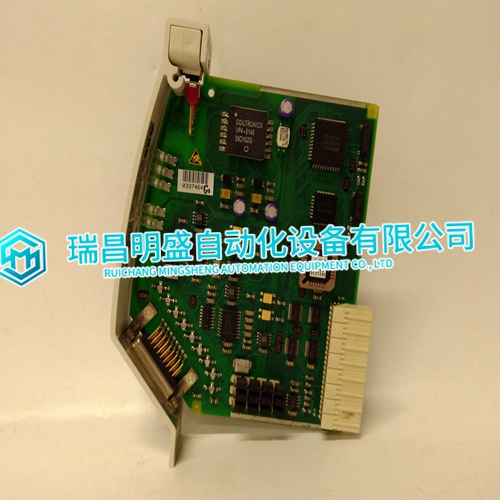

Instructions on the use of the FI820F 3BDH000031R1 automation module

Instructions on the use of the FI820F 3BDH000031R1 automation module

If the product is used as a UL-approved product, the external power supply must be provided from a limited voltage/current circuit*1 or class 2 power supply*2. *1 A limited voltage/current circuit is a UL508-approved isolated power supply which is limited to 30 VAC or 42.4 V peak in output voltage and to 8 A in output current. *2 A class 2 power supply is a UL1310-approved power supply which is tested and proved by UL that its output voltage is 30 VDC max. and its output current is 8 A max.

Environmental Conditions for Installation within a Panel Enclosure Refer to the following considerations when designing the interior of the panel enclosure to ensure operability, maintainability, and environmental durability. Figure A3.1 shows a typical example of a layout within a panel enclosure.Condensation may occur due to sudden temperature changes resulting from the turning on and off of an air conditioner. If condensation occurs on any of the circuit boards, the instrument may malfunction due to shorted internal circuitry. If there is a risk of condensation, either keep the power turned on at all times, or use a space heater or other alternative means to keep the controller constantly preheated.

Temperature Considerations

- Provide good ventilation to prevent heat from being trapped inside the panel enclosure. If two or more FA-M3 controller units are installed vertically within the same panel enclosure, provide a clearance of at least 8 cm between them. - Ensure that the upper and lower vents near the FA-M3 controller are not blocked either by wiring or otherwise. - Avoid mounting the controller directly above any equipment that generate large amounts of heat. - If there will be times where the temperature inside the panel enclosure reaches 55°C (131°F) or higher, use a fan or an air conditioner for cooling. Consider providing a safety mechanism such as a temperature sensor inside the panel enclosure to raise an alarm upon failure of the fan or air conditioner as such failures may adversely affect the system. Conversely, if temperature is likely to fall below 0°C (32°F) during morning startup, include a small heater, lamp, or other heat source to preheat the panel enclosure. Figure A3.2 shows examples of cooling systems.

Vibration and Shock Considerations

- As a countermeasure to keep shock or vibration below the specified limit, place the panel enclosure as far away as possible from any source of vibration or shock, or place the panel enclosure on vibration-proof rubber. - As a countermeasure to keep mechanical shock from electromagnetic switches mounted inside the panel enclosure below the specified limits, install such devices on vibration-proof rubber. CAUTION Be wary of any vibration and shock to the hard disk module. Any mechanical vibration or shock occurring during transportation of equipment or facilities into which the FA-M3 has been assembled must also be within the specifications limits. The specification range for vibration and shock is especially stringent for the hard disk module, as compared to other modules. When transporting, use the same packaging in which the product was originally shipped.