Industry news

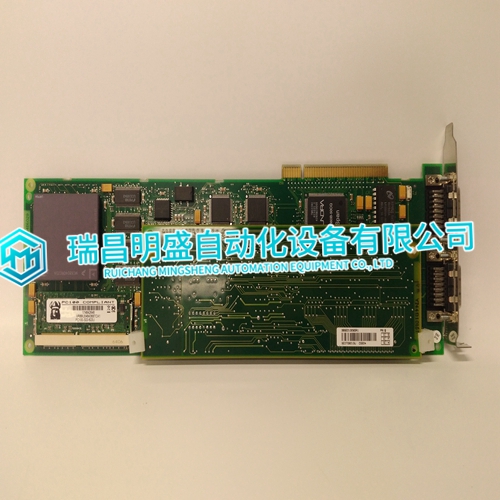

PU516 3BSE013064R1 Contact module USES data

PU516 3BSE013064R1 Contact module USES data

Troubleshooting If any of the conditions described above have occurred, troubleshooting is required to determine the repairs that are necessary. Precautions Because the module contains static-sensitive electronic parts, follow these precautions while troubleshooting: • Use a grounded, conductive work surface. Wear a high impedance ground strap for personal protection. • Do not operate the module with static sensitive devices or other components removed from the product. • Do not handle static sensitive devices more than absolutely necessary, and only when wearing a ground strap. • Rely on voltage measurements for troubleshooting module circuitry. Do not use an ohmmeter. • Use a grounded, electrostatic discharge safe soldering iron.Plumbing to module leaks or is contaminated. Chamber pressure is too high due to leak, contamination, or pump failure. Power supply or output cable is improperly connected or faulty

Pressure reading is inaccurate.

Micro-Ion gauge is contaminated. Micro-Ion gauge is damaged (for example, by reactive gas) or contaminated. Temperature or mechanical vibration is extreme. If Micro-Ion gauge is contaminated, degas the gauge or replace gauge assembly. If temperature or vibration is extreme, relocate module or eliminate source of heat or vibration. Indicated pressure is different than pressure indications from other measurement devices. Micro-Ion gauge is defective Replace the gauge assembly. Module LED status indicator is solid Red. A fault caused the Module to stop reading pressure. See the DeviceNet Error Codes in Section 3.16 DeviceNet Error Codes on page 44.If plumbing leaks or is contaminated, clean, repair or replace plumbing. If pump failed, repair or replace it. If cable is improperly connected or faulty, repair or replace cable To prevent electrical shock, turn OFF electrical power before servicing the Micro-Ion Vacuum Gauge Module. Do not touch any gauge pins while the gauge tube is under vacuum or connected to a controller.

This test should only be performed while

the ion gauge is exposed to atmospheric pressure and the electronics is removed from the gauge. If a problem with pressure measurement is traced to the Micro-Ion Module, the gauge may be tested with an ohm meter. This test can detect open filaments or shorts between gauge elements. This test may not detect inaccurate pressure measurement due to gauge contamination or vacuum leaks. 1. Turn OFF power to the module. 2. Disconnect the cables from the module. 3. Remove the Micro-Ion Module from the vacuum system. 4. Remove the four Phillips head screws from the gauge collar plate as shown in Figure 4-1.Be aware that an electrical discharge through a gas may couple dangerous high voltage directly to an ungrounded conductor almost as effectively as would a copper wire connection. A person may be seriously injured or even killed by merely touching an exposed ungrounded conductor at high potential. This hazard is not peculiar to this product.