Home > Product > DCS control system > 1C31132G01 Output module personality

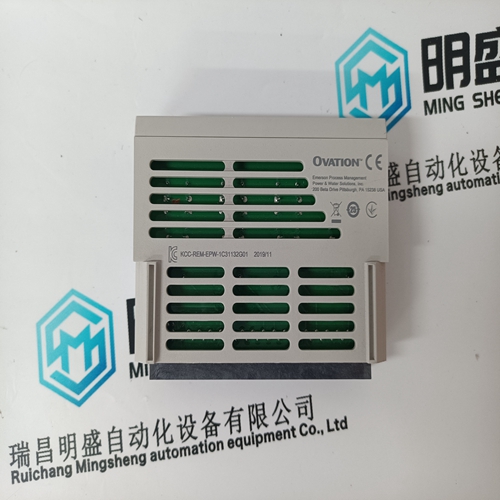

1C31132G01 Output module personality

- Product ID: 1C31132G01

- Brand: EMERSON

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:1C31132G01Output module personality

- Get the latest price:Click to consult

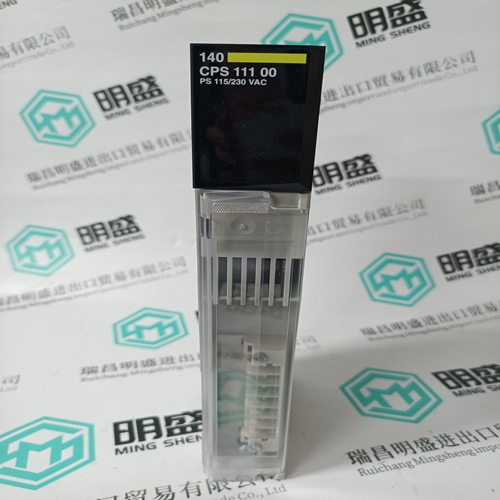

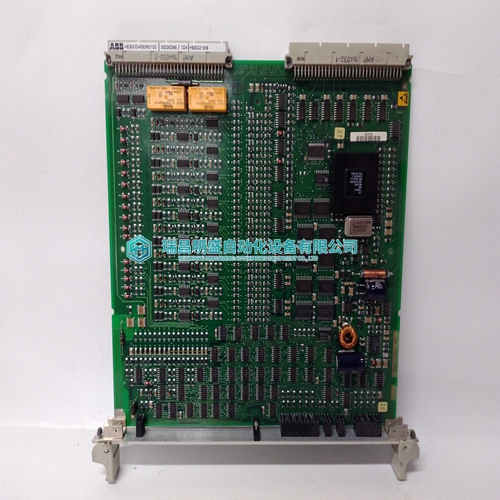

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

1C31132G01 Output module personality

If a protective separation of the power DC link from the supply line is required, for example, work must be performed on the power unit (connect/disconnect motor), also ensure that all parallel connections to the power infeed are electrically isolated using switching contacts. In this case, a possible user–specific external connection between the electronics power supply and the power DC link must be taken into consideration. In order to shutdown the system when the power fails using the DC link energy, it is possible to have a connection between the P500/M500 and P600/M600 terminals. If a safe electrical separation is required for this interconnection, the electronics, also possibly the monitoring module, must also be disabled or this electronic power supply – power DC link connection must be separated safely and reliably because otherwise the electronic power supply of the power DC link can be charged from the auxiliary DC link. In the setting–up mode (only with 1FT5 motors), the connection between the electronics power supply and the power DC link must also be disconnected.

ready signal in the I/R module

The ready relay can only pull–in if pre–charging has been completed and the internal line contactor has pulled–in. When the power fails (line supply failure), the I/R module is internally inhibited. This means that the I/R module can no longer regulate the DC link voltage which means that no braking energy can be fed back into the line supply (no regenerative feedback). The drives are not inhibited, but the ready relay drops– out after the power failure detection time with a delay that depends on the line supply impedances. When the line supply is switched off using the main switch or other switching elements, ensure that the terminal 48 on the I/R module is open at least 10 ms beforehand if other external parallel loads are also present in the switchgear cabinet (see Chapter 7.3.6).

Description of the interfaces and functions

The electronics power supply integrated in the NE module supplies the connected drive modules via the equipment bus; and, for the digital drive groups 611 digital, also the SINUMERIK controls 840D or 810D integrated in the group. The number of modules that can be connected is limited. The connection power of the modules that can be connected is determined by adding the assessment factors regarding the electronics points (EP) and gating points (AP). If the power requirement exceeds the power rating of the NE module power supply, then the drive group must be expanded by one or more monitoring modules. The overall system then includes two or more electronic systems that are independent of one another. Further, the charge limit of the DC link must be carefully observed (refer to Chapter 1.3). Enable signals/commands or fault signals only effect the axes connected to a common equipment bus. The equipment bus is interrupted between the last axis after the NE module and the monitoring module.