Home > Product > DCS control system > 1C31233G04 Analog voltage module

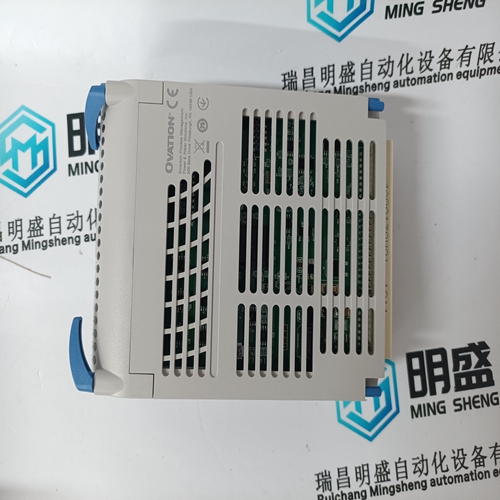

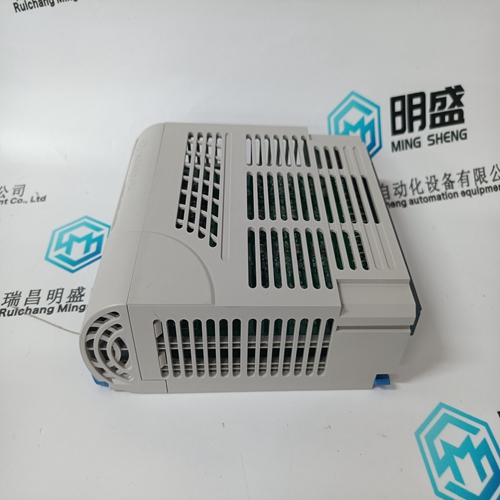

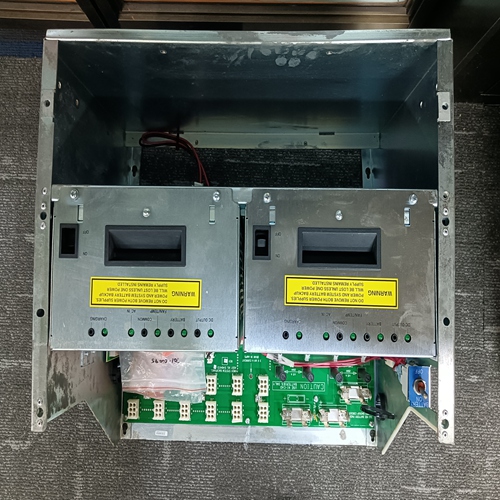

1C31233G04 Analog voltage module

- Product ID: 1C31233G04

- Brand: EMERSON

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:1C31233G04Analog voltage module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

1C31233G04 Analog voltage module

In the application example, Fig. 8-11 the SIMODRIVE 611 drive group comprises a 1PH7 main spindle drive and three 1FT5 feed drives as an example for a machine tool. The drive–related control essentially includes the safety–relevant, 2–channel hardware control with the associated PLC functions. The PLC control handles the coordinated sequence of the drive control through logic operations; however it does not handle any safety–relevant functions. The NC/FM (positioning control), with the setpoint and actual value interface as well as the machine control of the user side, is not discussed in the subsequent text. This is the reason that they are only depicted from the essential principle. Control Category in accordance with EN 954–1 The 2–channel system structure of controls =4 to =6 corresponds, when the individual components are correctly used, to control Category 3 according to EN 954–1. This means that if a single fault occurs in the system, then the safety function must still be kept.The user should evaluate the control Categories of the additional circuits =7 to =9. This depends on how he uses the third–party components/monitoring devices that he selected etc. and how they are integrated into the basic control in a safety–relevant fashion.

For machines that are to be classified

in a lower Category, e.g. 1 or 2 according to EN 954–1, after the hazard analysis/risk evaluation or type C Standard, the control can be principally derived from these circuit examples and implemented in a more simple, single–channel, system structure! This also applies to the sub–areas/sub–functions of a machine that, for example, according to type C Standards, must be implemented with either a lower or higher control category, deviating from the basic machine. For example, after the danger analysis/risk evaluation it can also be necessary that a hydraulic/ pneumatic clamping unit must be controlled in the work area using a two– handed control device in accordance with category 4.The 2–channel system structure is achieved in this application example: First shutdown path: The power feed to the drive motors is disconnected via the start inhibit functions in the drive modules. The shutdown is realized using terminal 663. The positively–driven feedback signal contact of the start inhibit relay via terminal AS1–AS2 is cyclically monitored and intervenes in the EMERGENCY STOP circuit of the safety relay. For a detailed description of the start inhibit function, refer to Section 8.5.

Second shutdown path

The line contactor in the NE module galvanically disconnects the line supply from the DC link of the drive modules. The shutdown is realized using terminal 48 at the same time (simultaneously) with the de–energizing of the contactor coil in a safety–relevant, electrically isolated fashion using terminals NS1– NS2. The shutdown is realized, for example, when stopping in an emergency, from fault signals received from the drive system or via the start inhibit monitoring when a fault condition occurs. After each power–off cycle, the forced normally closed contact 111 – 213 of the line contactor is monitored in the feedback circuit of the EMERGENCY STOP safety relay. For a detailed description of the line contactor, refer to Section 8.2.2. For an EMERGENCY STOP, the drives are stopped in Stop Category 1 according to EN 60204–1; 9.2.2: ”Controlled stopping” – the power feed is only interrupted when the motor has come to a standstill. Circuit examples =2 and =3, shown in Section 8.7, can be used for basic and average applications