Home > Product > DCS control system > 5X00500G01 Channels of contact module

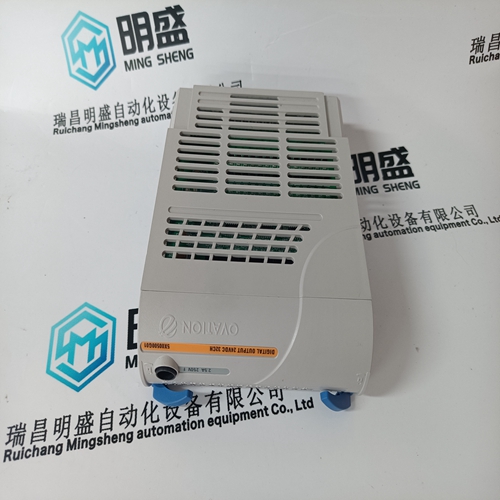

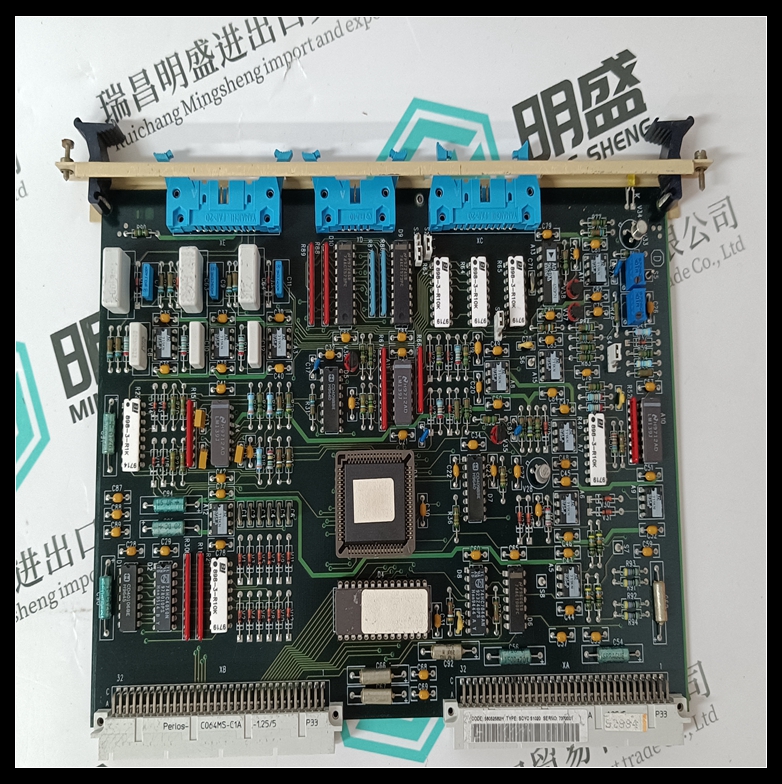

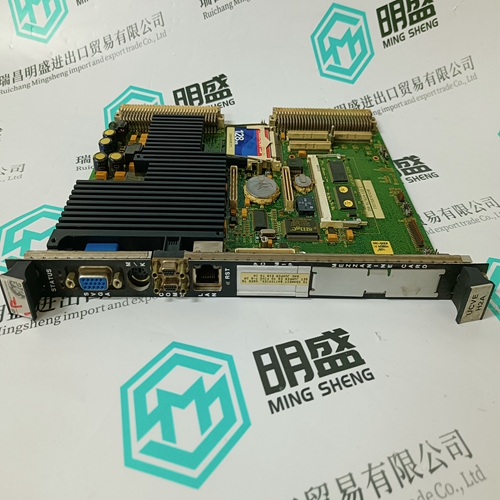

5X00500G01 Channels of contact module

- Product ID: 5X00500G01

- Brand: EMERSON

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:5X00500G01Channels of contact module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

5X00500G01 Channels of contact module

Optional: External standstill monitoring closed via terminal 77–78. The interlocking solenoid of the door position switch –S11 is energized and the safety relay –K11 and contactors –K13/–K14 are de–energized via the position monitoring function of the solenoid. The drives are shutdown in a safety–relevant fashion through two channels via the interlocking circuit, terminals 611–612/613–614. The protective door is initially just released, but is still closed, relay –K17 is energized. Using the PLC, e.g. sub–functions of the user–side machine control, that are still not hazardous, can be executed.

Armature short–circuit braking is only possible when using permanent–magnet motors and is used, for example, when passing end position limit switches, when the power fails, for fault signals or EMERGENCY STOP with some delay. When a software limit switch is passed, the fault/error is often in the NC, PLC or in the drive module itself. Electrical braking beyond the limit position limit switches according to circuit =8 is therefore no longer possible. For critical drives, e.g. vertical axes, in cases such as these, emergency braking is possible using armature short–circuit braking or optionally using a fast shutdown with a holding brake implemented with the appropriate hardware. The braking torque for armature short–circuit braking is optimized using the additional braking resistor in the motor circuit.

Normally

the end position (end stop) of the traversing range of the axes in the machine is monitored using software limit switches; these become active after the reference point approach. If, in a fault situation, a software limit switch is passed, and therefore a hardware limit switch actuated, then contactor =4–K21 is de–energized (opened) via the interlocking circuit, terminal 81–82 in the EMERGENCY STOP circuit. The drives are braked at the current limit and are then stopped. However, electrical braking of an axis is only effective if there is an appropriate distance for the braking travel between the hardware limit switch and the mechanical end stop of the axis. The actuated end position limit switches can be decoded using PLC inputs. In the setting–up mode, the axis can be moved away in the opposite direction using key–operated switch –S13 and button =5–S11 – ”agreement

Armature short–circuit

The pulse enable is withdrawn via terminal 663 when the limit position limit switch is actuated/passed or when the power fails. The armature short–circuit contactor –K11 is simultaneously de–energized (opened). The drive is braked after the contactor drop–out time. The interlocking circuit, terminal 91–92, is simultaneously opened therefore initiating an EMERGENCY STOP function for all of the drives. A varistor is connected to the contactor coil in order to achieve a short contactor dropout time. The selected auxiliary contactor from the SIRIUS series of industrial controls with mounted, four–pole auxiliary contact element fulfills ”protective separation” between the control voltage and the 690 VAC motor circuit. For operation with power failure and when the +24 V control voltage is buffered, or for other shutdown functions, the circuit must be appropriately adapted to the particular application. Holding brake The fast application of the holding brake, independent of the PLC cycle time using the armature short–circuit contactor, supports braking. When compared to armature short–circuit braking, there is a delay before the holding brake actually closes and starts to brake. In the setting–up mode, the axis can be moved away using the key–operated switch –S13 – move away from end position – and pushbutton =5–S11 – agreeme