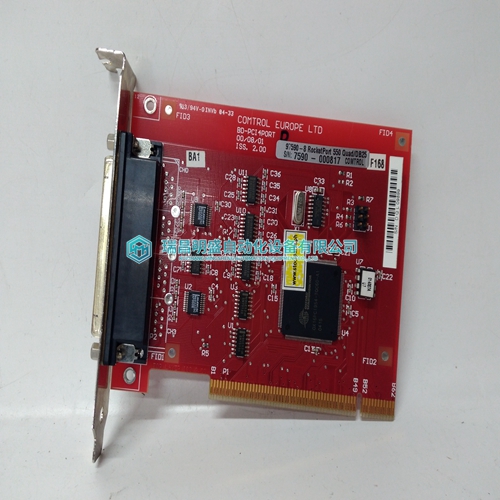

Home > Product > Gas turbine system > GE 97590-8 BD-PCI4PORT Expansion CARDS

GE 97590-8 BD-PCI4PORT Expansion CARDS

- Product ID: 97590-8 BD-PCI4PORT

- Brand: GE

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:GE97590-8 BD-PCI4PORTExpansion CARDS

- Get the latest price:Click to consult

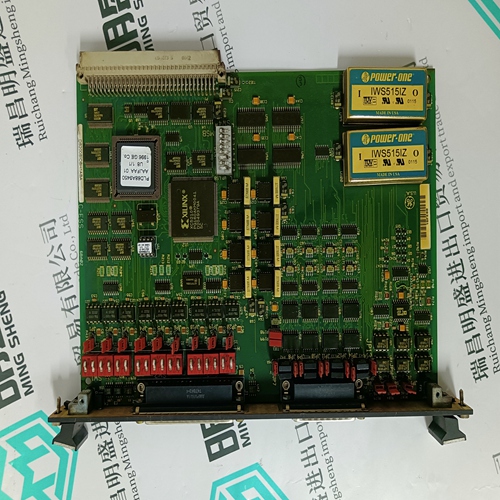

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

GE 97590-8 BD-PCI4PORT Expansion CARDS

The B885-002 ASCII / BASIC Module runs user-written BASIC programs independently of the controller’s memory logic and scan. It also performs READ and WRITE commands to and from serial devices connected to either of the module’s two RS 232/422 ports (jumper selectable). In addition, its real-time clock/calendar allows the module to run a BASIC program or flag and return a value to the PLC at a user specified date and time. The module provides report generation, interactive operator interface, high level math, peripheral communication and data storage. Using a dumb terminal or an IBM personal computer with Emulator Software (Part # SW-E885-1DA), you program the module’s 53K of user memory. If you need more memory, you may provide an additional 32K of user EPROM. You can designate part of the memory as retentive variable memory to store formulas or other process parameters.

Increases the value of the selected set point (in the setup menu). In daily use, this button function is used to switch between displayed percentage or real value of produced power (kW), reactive power (kvar) and apparent power (kVA) in View 3 (V3). Selects the underscored entry in the fourth line of the display.

Display menu systems

The display includes two menu systems which can be used without password entry: View menu system This is the commonly used menu system. 15 windows are configurable and can be entered by using the arrow push-buttons. Setup menu system This menu system is used to set up the unit, and if the user needs detailed information that is not available in the view menu system. Changing of parameter settings is password protected. 3.2 Menu structure 3.2.1 Entry window When the unit is powered up, an entry window appears. The entry window is the gateway to the other menus. It can always be reached by pressing the BACK push-button three times.1. First display line: Operational status or measurements 2. Second display line: Measurements relating to operational status 3. Third display line: Measurements relating to operational status 4. Fourth display line: Selection of setup and view menus In the view menus, various measured values are on the display

Alarm handling

When an alarm occurs, the unit will automatically go to the alarm list for display of the alarm. This function can be disabled or enabled. For further explanation, please see the Designer’s Reference Handbook. If you do not want to read the alarms, use the BACK push-button to exit the alarm list. If you want to enter the alarm list later, use the INFO push-button to jump directly to the alarm list reading. The alarm list contains both acknowledged and unacknowledged alarms, provided that they are still active (that is the alarm condition is still present). Once an alarm is acknowledged and the condition has disappeared, the alarm will no longer be displayed in the alarm list. This means that if there are no alarms, the alarm list will be empty.An event is for example closing of breaker and starting of engine. An alarm is for example over-current or high cooling water temperature. A battery test is for example test OK or test failed. The logging of data is divided into three different groups: ● Event log containing 150 loggings ● Alarm log containing 30 loggings ● Battery test log containing 52 loggings