Home > Product > DCS control system > 216NG63A HESG441635R1 HESG216877K module

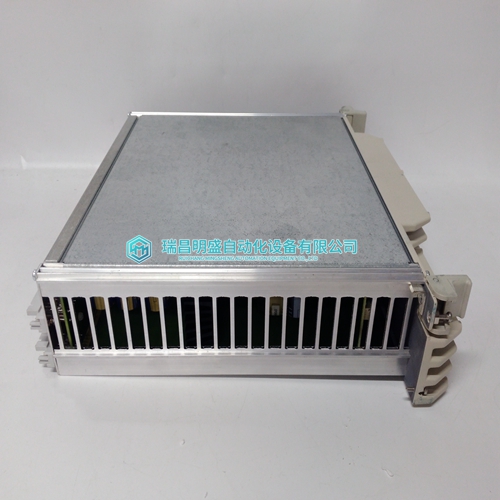

216NG63A HESG441635R1 HESG216877K module

- Product ID: 216NG63A HESG441635R1 HESG216877K

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:216NG63A HESG441635R1HESG216877Kmodule

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

216NG63A HESG441635R1 HESG216877K module

Application The LSU-112DG is a control unit for control of the prime mover in a power unit. The LSU-112DG can control the power unit - in stand-alone mode, performing frequency control - parallel with grid, performing power control - parallel with other power units, performing frequency and power control The unit is designed for connection to a mechanical speed governor, however in conjunction with the DEIF electronic potentiometer type EPN-110DN or EPQ-96 it can control electronic speed governors as well. The LSU-112DG has a built-in frequency transducer. If a very stable frequency is wanted, an external frequency transducer common for all the LSU-112DGs in the power plant can be connected. If a number of power units are to be synchronised to the busbar at the same time, the frequency may likewise be controlled externally.

The LSU-112DG is equipped with an unload input. When activated this input will control the power unit to zero power, and at the same time the power output of the LSU-112DG is disconnected from the paralleling line. The calibration of the LSU-112DG is done so it matches its power unit. This means that load sharing between power units with different size will be performed according to the actual size of the individual power unit in the plant. For example a 100 kW PU and a 150 kW PU running in parallel will share a total load of 125 kW into 50 kW and 75k W. If the 150 kW PU is derated to 100 kW by means of the DERATING potentiometer on the front of the LSU-112DG, the load in the above example will then be shared equally between the two power units.

Function

The LSU-112DG is measuring the voltage and the current from which the frequency and the power produced by the power unit are measured. The built-in power transducer is based on an I x cos phi principle. The following couplings are available: - 1W(4) – single phase - 1W3 – 1-element 3-phase, 3-wire, balanced load If unbalanced load can be expected, an external power transducer with an output of 4 to 20 mA can be connected to the LSU-112DG. In this case the built-in I x cos phi transducer is automatically interrupted. The power and frequency measured by each LSU112DG are fed to two paralleling lines for comparison with the frequency (FS) and power (PS) of the other connected LSU-112DG. If L1 or L2 is disconnected from the LSU-112DG at the same time as a power unit in a power plant is disconnected from the power line (busbar), built-in relays in the LSU-112DG ensure that the power output and the frequency output of the associated unit are disconnected from the paralleling lines. Likewise the power and frequency outputs are disconnected if the auxiliary voltage to the LSU-112DG is disconnected.

Regulator output

The unit is provided with two contact outputs for speed control: Power and frequency control: The regulating speed of the servomotors for the prime mover is controlled by the built-in P controller of the LSU-112DG according to its setting for: TN (min. ON time): The min. duration of the control pulse when inside the proportional band Xp. XP (proportional band): The zone within which the pulse/pause ratio changes proportionally to the frequency/power deviation from the required value. TP (period time): The time between the beginnings of two subsequent relay pulses. Deadband: The zone within which no control pulses are emitted. Self-monitoring The LSU-112DG is equipped with a self-monitoring function. The function supervises the built-in microcontroller and hereby verifies if the programme is running correctly. The green LED marked “POWER” is connected to this function. Constant green light indicates that the supply voltage is accepted and the unit is running correctly. Flashing green light 2-3 Hz indicates that the supply voltage is accepted but the unit is running incorrectly. In this situation the status output terminals 17 and 18 are activated (open).