Home > Product > DCS control system > REX010 HESG324426R0001 HESG324389 Control of the host

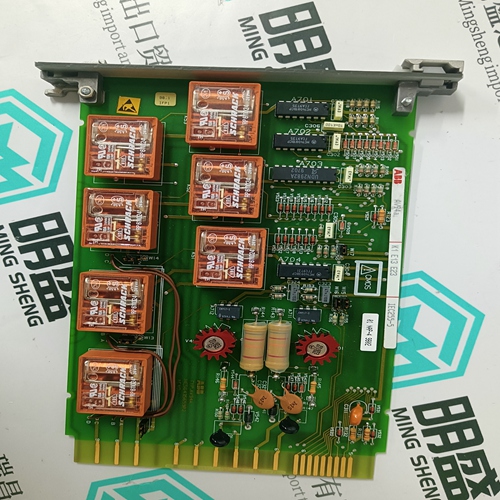

REX010 HESG324426R0001 HESG324389 Control of the host

- Product ID: REX010 HESG324426R0001 HESG324389

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:REX010 HESG324426R0001HESG324389Control of the host

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

REX010 HESG324426R0001 HESG324389 Control of the host

• Torque screwdriver, flat 0.6 mm x 3.0 mm (1/40 inch x 1/8 inch), for dc power wiring terminals • Torque screwdriver, flat 0.4 mm x 2.0 mm (1/64 inch x 5/64 inch), for field wiring terminals • 2 x wrench, open end, 10 mm, for ground stud nuts • Allen key (hex wrench), 2.5 mm, for plug and sockets assemblies used with extension cables Special Tools • Long nosed pliers to remove the fuses on termination assemblies. • Digital voltmeter, for troubleshooting activities • Resistor 1k8, for troubleshooting analogue input modules • Resistor 1k 1W, for troubleshooting digital output modules • Resistor 250R 1W, for troubleshooting analogue output modules

The maintenance of the AADvance controller requires the following test equipment. 1. Digital voltmeter • DC voltage range 0 V to 32 Vdc or better. • Resistance resolution 0.01 W or better. 2. Current simulation instrument • Output range 4 mA to 20 mA with an accuracy better than 0.05 mA. 3. Bench power supply • Output range 0 V to 32 Vdc.

Preventive Maintenance Safety

systems are designed to run continuously without manual intervention. However, some manual preventive maintenance must be done to make sure the system stays available and healthy. This chapter describes the preventive maintenance activities for an AADvance® controller. Preventive Maintenance Schedule The preventative maintenance tasks must be done at the following intervals: ARC FLASH HAZARD: ARCS AND EXPLOSION RISK IN HAZARDOUS AREAS If you connect or disconnect wiring, modules or communications cabling while power is applied, an electrical arc can occur. This could cause an explosion in hazardous location installations. Do not remove wiring, fuses, modules or communications cabling while circuit is energized unless area is known to be non-hazardous. Failure to follow these instructions may cause personal injury. Table 1 - Recommended Schedule for Preventive Maintenance Testing of the logic solver and its related field devices must be carried out according to the applicable plant or process safety analysis and the safety integrity validation. The manual test interval is used by the Probability of Failure on Demand (PFD) data analysis as part of the certification process.

Check Wiring Terminals

To examine the wiring terminals do the following: • Examine the field, power and network wiring and look for any signs of physical stress such as chafing. • Tighten any loose terminal screws to help prevent open circuits causing trips, see torque values in note above. Check Seating of Plug-in Components To examine the seating of plug-in components, do the following: • Examine the AADvance controller and make sure all plug-in items cable assemblies and base unit bus connectors, are correctly seated. Check Physical Condition and Environmental Conditions To examine the physical condition of the controller and the environmental conditions, do the following: • Examine the AADvance controller assemblies for contamination, corrosion, dampness and dust. • Look for unauthorized modifications. • Look for exposed parts (where covers are missing), bare wires and damaged insulation. • Make sure that local ventilation and air conditioning systems are operating correctly.