Home > Product > Robot control system > PARKER EVM32-BASE 1019422 Automation module

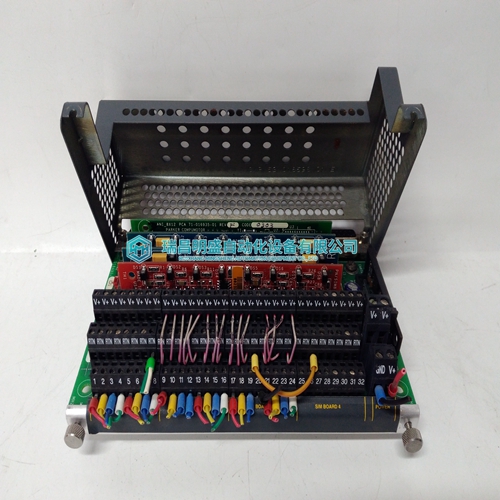

PARKER EVM32-BASE 1019422 Automation module

- Product ID: EVM32-BASE 1019422

- Brand: PARKER

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PARKEREVM32-BASE 1019422Automation module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

PARKER EVM32-BASE 1019422 Automation module

The remote fault reset/join is enabled and configured as part of the application, then triggered by a remote client writing to configured MODBUS variables. If it does not work as expected, then check the configuration and client as described below. Trouble shooting the application • Ensure that the Remote Fault Reset/Join has been enabled by configuring the enabler key to a non-zero hexadecimal value. • Ensure the required MODBUS variables have been defined and connected to the correct outputs on the processor I/O board as follows: • A BOOL output, configured as a MODBUS coil, connected to the "Perform Remote Fault Reset" output. • A BOOL output, configured as a MODBUS coil, connected to the "Perform Remote Fault Join" output. • A WORD output, configured as a MODBUS holding register, connection to "Allow Remote Fault Reset MSB". • A WORD output, configured as a MODBUS holding register, connection to "Allow Remote Fault Reset LSB". • Ensure "Allow MODBUS Write" is enabled for the four MODBUS variables.

Trouble shooting the remote client

• Ensure that the client is writing the correct values to the variables connected to "Allow Remote Fault Reset MSB" and "Allow Remote Fault Reset LSB" before triggering the reset/join. The combined values must match the enabler key. • Ensure that the client is writing to the correct BOOL trigger variable, "Perform Remote Fault Reset" or "Perform Remote Fault Join", depending on the function required. • To trigger the reset/join, the BOOL trigger variable must transition from FALSE to TRUE. Set the Real Time Clock Manually If the system has only one controller and does not have a different time server, you have to set the processor real-time clock manually using RTC variables. The following procedure assists in setting the clock: Set up the following variables in the Dictionary RTC Control Variables (all BOOLEAN Outputs) • RTC Control: RTC_Read • RTC Control: RTC_Write • RTC Control: Year

Procedure to Check the Current Date and Time

1. Wire the processor variables. Refer to the topic "Wire Processor Variables". 2. Build and download the program or perform an on-line update. 3. Check the current date and time settings: • Enter Debug mode • Request IXL Restricted Access • Force the RTC Read Boolean and all the time fields in the RTC Control Variables to TRUE

Procedure to Set the Date and Time 1. Unlock the RTC Read variable so it turns FALSE. 2. Select each RTC Program variable and enter the date and time values. 3. Toggle the RTC Write variable TRUE then FALSE to write the new date and time setting to the processor. 4. Lock and force the RTC Read variable to TRUE. 5. The RTC Status now displays the new date and time of the processor. 6. Unlock all the RTC Control variables.