Home > Product > Servo control system > HIMA F3 DIO 88 01 controller

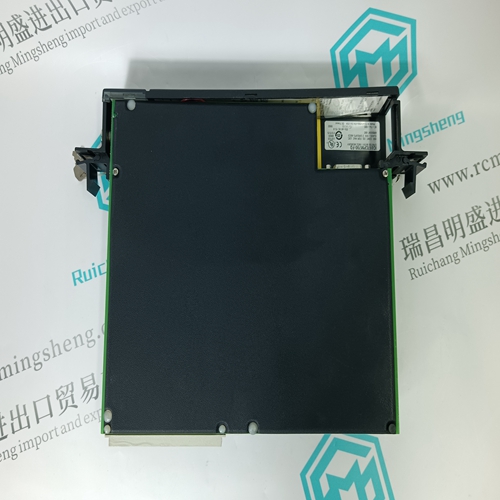

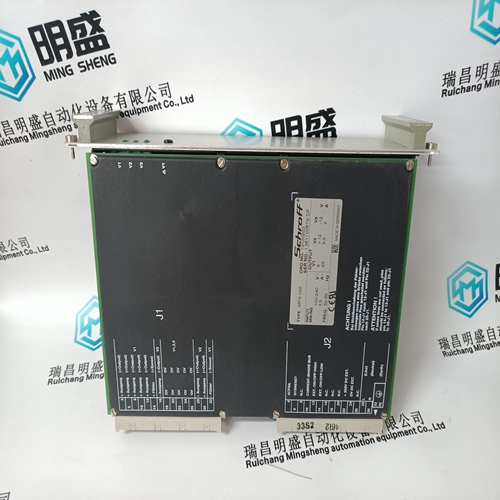

HIMA F3 DIO 88 01 controller

- Product ID: F3 DIO 88 01

- Brand: HIMA

- Place of origin: Germany

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HIMAF3 DIO 88 01controller

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

HIMA F3 DIO 88 01 controller

The ACS2000 4KV has three sections, the Incoming/Control section, the Input Filter (IFU) section and the Phase Module section. This manual is divided, by frame size, into those sections showing the corresponding spare parts in each section. ABB reserves the right to change part numbers at any time. If you have difficulty identifying the part you need, please feel free to contact Technical Support.

ABB part number 2UEA003150 has replaced part number 3BHB024327R0001. This has also changed the inrestor configuration from a quantity four (4) inrestors to a quantity of two (2). Please note: If your drive currently utilizes part 3BHB024327R0001 and one of the inrestors fails, all (4) inrestors will need to be removed and replaced with two (2) part number 2UEA003150 inrestors.

Available in a range of configurations to match your needs, the 32 channel CEI-530 provides complete, integrated databus functionality for ARINC 429, ARINC 575 and selected 2-wire, 32- bit protocols. The CEI-530 supports maximum data throughput on all channels while providing onboard message scheduling, label filtering, multiple buffering options, time-tagging, error detection and avionics-level I/O discretes, with support for either 33 MHz or 66 MHz PCI interfaces. Configurations with support for ARINC 717,

Renishaw Inspection Plus Software Cycles

• X or Y or Z single surface measure • Web/pocket measure • 4 point bore/boss measure • Internal/external corner • 3 point bore/boss vector measure • Angled XY surface measure • Holes on a pitch circle diameter (PCD) ie: Bolt hole patterns • 4th axis measure. Can be modified for 4th and 5th axis applications • Stock allowance • Multi-stylus calibration with option to run multiple probes with different stylus angles • Calibration on a ring or sphere available • XYZ single surface vector measurement • Optional software available for true 3D and form measurement • Reduced set-up & calibration routines provide more time for machining cycles • Improved process control and quality • Reduced, rework, concessions and scrap • Less operator intervention • Long service life • Fast to install & easy to use • Used with automatic tool changers Features • Proven Rengage Strain Gage Technology offering .025µm repeatability at 2σ • Secure Frequency Hopping, Spread Spectrum (FHSS) Technology • Globally recognized 2.4GHz waveband — compliant with regulations in all major markets • Sealed to IPX8 for usse in the harshest machining environments • Compact probe design (40 mm Ø x 50 mm long) • Unrivalled performance on complex 3D shapes, ideal for 5-Axis machine tools • Wide variety of shanks to fit nearly all machining centers

Architecture

CEI-530 features include independent, software programmable data rates and parity, error detection and automatic transmit channel slew rate adjustment. 2 MBytes of on-board RAM provide large transmit and receive data buffers. All channels operate independently. Discretes support TTL to 16 avionics-level inputs and 16 outputs while open-collector outputs enhance application flexibility. Data Handling On-board firmware, large data buffers, and a high-level API are integrated to provide total flexibility in monitoring and generating ARINC bus traffic. Simultaneous Scheduled and Burst Mode (FIFO) messaging is supported on all ARINC 429 transmit channels. Each ARINC 429 receive channel provides simultaneous Dedicated and Buffered Mode storage, along with label/SDI filtering. Three different methods are provided to buffer received data: • Buffered Mode utilizes a separate circular buffer for each channel. • Merged Mode combines all received data into a single, time-sequenced circular buffer. • Dedicated Mode provides a snapshot of the very latest data.