Home > Product > PLC programmable module > NI SCXI-1300 Channel module

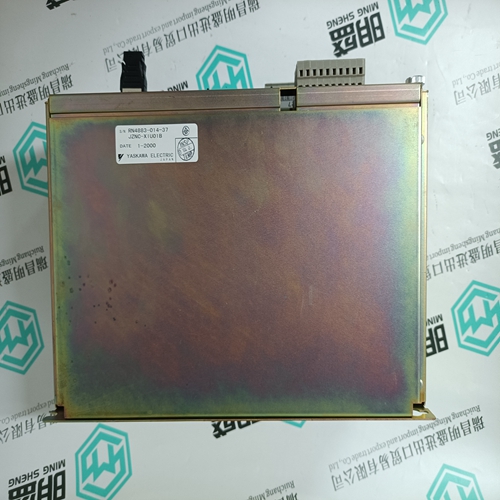

NI SCXI-1300 Channel module

- Product ID: SCXI-1300

- Brand: NI

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NISCXI-1300Channel module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

NI SCXI-1300 Channel module

The ProAct™ Integrated Speed Control (ISC) is an electric actuator with an integrated electronic driver capable of diesel or gaseous engine speed control or positioning tasks. The ProAct ISC can be mounted on-engine to control a diesel fuel rack or gaseous throttle via linkage or integrated throttle body. The ProAct ISC accepts a speed input from an MPU and can accept a position command signal from another device in the system such as an engine control module. Configured as a speed control, the ProAct ISC offers speed control with softwareselectable speed set points, dynamics, fuel limiting, and start/stop behavior. Configured as a positioner, the ProAct ISC offers position control with software selectable CW/CCW operation and field calibration.Pumps for diesel and heavy fuels that provide the high fuel injection pressures required to achieve the ultimate in high fuel efficiency, low emissions engine designs.

Diesel Engine Products

Tightening emissions standards, cost pressures, and dispersed application requirements have resulted in a more challenging business climate for the industrial diesel engine industry. To meet these demands, Woodward offers comprehensive energy control system solutions for every size, type, and application of industrial diesel engine made. From the smallest diesel in mobile and stationary equipment to the largest heavy fuel engine in marine and power applications, Woodward offers a tightly integrated control system solution that perfectly matches the requirements. Based on four core technologies—Fuel and Air Delivery, Combustion Control, Electronic Controls and Software, and Systems Integration—Woodward system solutions are custom designed to maximize your engines’ fuel economy and efficiency, and reduce engine emissions.

Turbocharger Bypass and Wastegate Valves

The Flo-Tech™ integrated actuator/butterfly valve body is designed for direct replacement of conventional turbocharger bypass valve with actuator and linkage. The valve body will provide equivalent maximum flow rates of standard butterfly valve bodies of the same diameter. The Flo-Tech integrated actuator/valve body requires no actuator or linkage. (product spec 04140) The Glo-Tech™ is a modulating, all electric wastegate/bypass valve, which is capable of handling hot (600 °C) exhaust gasses for gas or diesel engines. The Glo-Tech valve provides engine manufacturers a method to reduce emissions, increase efficiency and reliability. The Glo-Tech has a bore of 60 mm and can accept an actuator case temperature of 100 °C.Woodward provides complete Common Rail Fuel Injection systems, including engine control unit (ECU), high-pressure fuel pump, high-pressure rails and pipes, flow control valve, and fuel injectors. The systems can use up to 1800 bar injection pressure in single and double wall piping and rail systems with integrated flow limiters. The modular pump has an integral flow control valve and pressure relief valve. The injector is capable of multiple injection events per cycle. The system is highly efficient and can match a wide range engine bores and speeds.