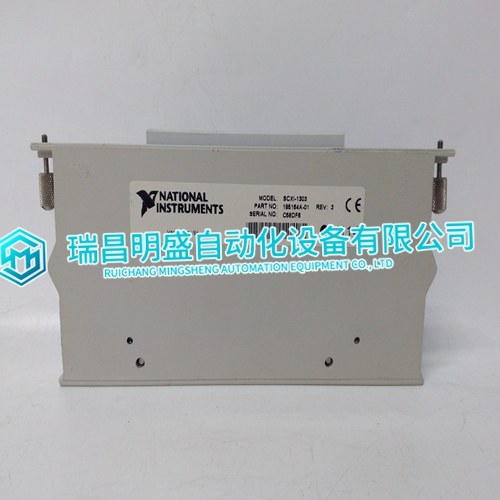

Home > Product > PLC programmable module > NI SCXI-1303 Measuring module

NI SCXI-1303 Measuring module

- Product ID: SCXI-1303

- Brand: NI

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NISCXI-1303Measuring module

- Get the latest price:Click to consult

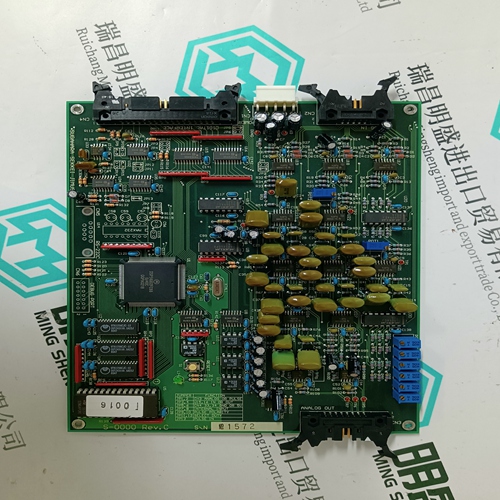

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

NI SCXI-1303 Measuring module

The Dyna 2000 and Dyna 2500 linear actuators provide accurate precise positioning with a minimal number of moving parts. Many of the moving parts normally associated with electric actuators are eliminated, prolonging the MTBF (mean time between failure). These actuators are easy to install by mounting near the fuel system and direct connecting to the fuel control rod or lever. In most installations, the normal rotary-torotary connection is eliminated, resulting in a more trouble-free and accurate control system. The actuator is suitable for installation on diesel, gasoline, or natural gas engines with fuel system force requirements of less than 13 pounds (58 N) of force. (product spec 03324) The Dyna 70025 integrated actuator for Stanadyne “D” series injection pumps is a proven all-electric, rotary actuator fully integrated into the cover of the Stanadyne pump. There are no brackets or external linkage, and the design is factory approved by Stanadyne. Installation is easy—simply remove the existing cover and install the new cover. Both a standard model and a completely sealed model are available.

The Dyna 7000 all-electric rotary actuator

provides 70 degrees of rotation in a small package. The actuator is applicable to gasoline, natural gas, and diesel engines. A direct connection between the actuator shaft and butterfly shaft is possible on carburetor and throttle-body applications. (product spec 36501) The L-Series Position Controller provides a building block approach to total engine management. The microprocessor-based bi-directional actuator design easily attaches to fuel pumps, mixers, or throttle bodies. The L-Series Position Controller accepts a position command and drives the 0–60 degree output shaft to the commanded position based on an internal shaft position sensor. The high-efficiency torque motor delivers 0.34 Nxm (0.25 lb-ft) nominally over 60° travel range to operate fuel or air control devices.The EM-80 and EM-300 are all-electric actuator systems that provide 40 degrees of actuator output rotation. Each system consists of a three-phase brushless ac motor which drives a high-precision planetary reduction gear box. A dedicated driver controls the actuator position and allows monitoring of most features. PC/Windows based software facilitates the system setup. The EM-80 and EM-300 are freely programmable to meet many customer requirements.

The EM-80 and EM-300 gear-motor actuators

are intended to be mounted on large diesel, gas, and gasoline engines, and on all types of turbines, to control the position of engine fuel racks, turbine fuel valves, turbine and turbocharger variable geometry, and to handle timing control. These systems are well suited for engines without a mechanical drive or hydraulic oil supply. The ProAct™ Digital Plus actuator is intended to be mounted on-engine to control varying functions including (but not limited to): fuel rack positioning, timing control, throttle valve, and wastegate positioning. The actuator is effectively a positioner with an integral driver, which will accept a position command signal from another device in the system such as a speed control. The ProAct Digital Plus actuator includes an integral digital driver capable of controlling the actuator, communicating with the outside control system, and containing on-board software and intelligence to realize monitoring and customizing functions.