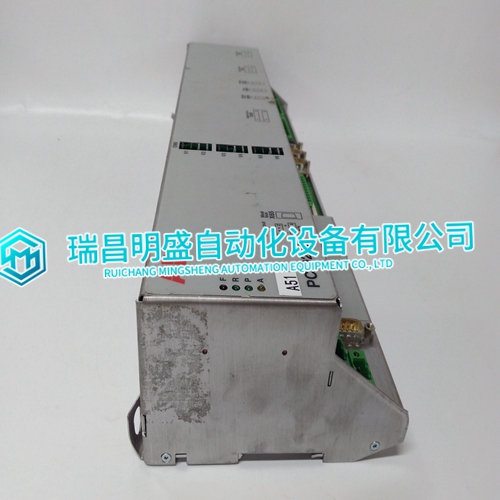

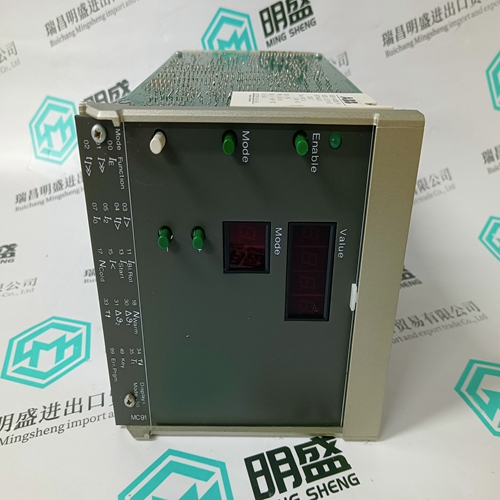

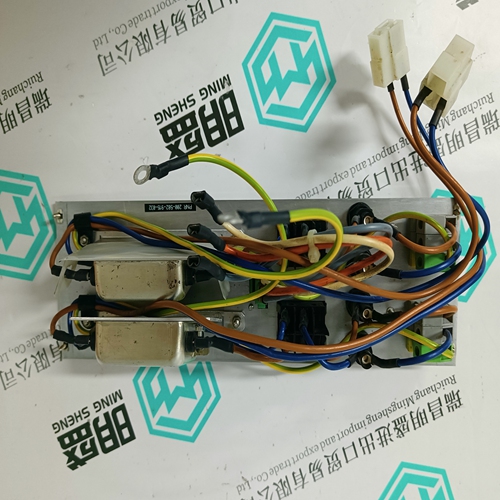

Home > Product > DCS control system > PCD235A101 3BHE032025R0101 Control module

PCD235A101 3BHE032025R0101 Control module

- Product ID: PCD235A101 3BHE032025R0101

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PCD235A101 3BHE032025R0101Control module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

PCD235A101 3BHE032025R0101 Control module

The many decades of Woodward experience with controlling engines and turbines, has been translated into a sophisticated suite of software tools specially tailored to prime mover applications. • GAPTM—Graphical Application Programmer is an IEC 1131-3 graphical programming environment with function blocks that are specialized for turbine and engine control applications. • Real Time Operating System (RTOS)—Provides the software architecture to meet the real-time requirements of the most complex turbine control problems. • NetSimTM—GAP can be compiled directly for PC Simulation with NetSim against engine models in ACSL, MATRIXx, Simulink or Matlab. • Service Tools—A range of options from on control displays for local control and service, debug, and configuration functions, to PC based windo The Electrohydraulic Power Cylinder (EHPC) provides the force to operate the control valves of a steam turbine. The EHPC is intended for use on mechanical drives or generator driven turbines. The EHPC integrates the actuator, pilot valve, electronic feedback device, final driver and the power cylinder into a single package, eliminating linkage and reducing hydraulic plumbing and wiring.

Custom Digital Controls

The MicroNet™ Controller is a state-of-the-art, programmable, digital controller. It can be programmed to control any prime mover and its associated processes, as well as system sequencing, high speed system monitoring, surge control, vibration monitoring and station control. The MicroNet™ digital control is available in both simplex and triple modular redundant (TMR) configurations. (product spec 85583) The AtlasPCTM control system is a new generation of turbine and engine control that provides the power of PC technology in a rugged and deterministic system. The flexible and powerful software tools and exceptional computational power make the AtlasPC control an ideal solution for controlling a variety of prime movers: • Steam Turbines • Industrial Gas Turbines (large and small) • Aero-derivative Gas Turbines • Gas and Diesel Engines • Hydro Turbines

The 2301D-ST is a microprocessor based control with integral application software designed for single-valve steam turbine applications. Like Woodward’s 2301A line of controls, this control is housed in a sheet-metal chassis and consists of a single printed circuit board. To facilitate unit retrofits, the 2301D-ST’s I/O terminals are located in the same general location as Woodward’s 2301A line of controls. This control is designed to perform the core control functions of a small steam turbine package. The application software is field configurable, allowing it to be configured and modified to meet site-specific requirements.

The TG-13E and TG-17E proportional actuators

are self-contained electrohydraulic actuators for use on steam turbines where isochronous control, load sharing, or other functions are required. They can be used with all available Woodward electronic governor controls and accessories. The TG actuators convert an electrical signal to a corresponding proportional output shaft position to position the valve which controls the flow of steam or energy medium to the turbine. They are intended for controlling small steam turbines driving such loads as alternators, dc generators pumps, compressors, fans or paper-making machines.

The TM-25LP and TM-200LP actuators are electrohydraulic, proportional actuators for positioning steam and fuel-control valves requiring low/high force linear inputs. (product spec 82451) The ProAct™ Digital Plus actuator is intended to be mounted on-engine to control varying functions including (but not limited to): fuel rack positioning, timing control, throttle valve, and wastegate positioning. The actuator is effectively a positioner with an integral driver, which will accept a position command signal from another device in the system such as a speed control. The ProAct Digital Plus actuator includes an integral digital driver capable of controlling the actuator, communicating with the outside control system, and containing on-board software and intelligence to realize monitoring and customizing functions.