Home > Product > Robot control system > Nikon 26002-5 Industrial Control DCS System Automation Equipment

Nikon 26002-5 Industrial Control DCS System Automation Equipment

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:Nikon26002-5Industrial Control DCS System Automation Equipment

- Get the latest price:Click to consult

Nikon 26002-5 Industrial Control DCS System Automation Equipment

Product Details Introduction

Industrial Control DCS (Distributed Control System) is an automation equipment and system used for monitoring and controlling industrial processes. DCS systems are typically composed of multiple components, including controllers, sensors, actuators, operating interfaces, and computers. The following are some automation equipment and their main functions in the industrial control DCS system:

PLC (Programmable Logic Controller): PLC is one of the core control equipment in the industrial control DCS system. They are used to execute various control logic, monitor sensor data, and control actuators and equipment to maintain stable operation of industrial processes.

Sensors and instruments: Sensors and instruments are used to monitor various process parameters, such as temperature, pressure, flow rate, liquid level, and chemical composition. They provide real-time data feedback to the DCS system for process monitoring and control.

Actuators and valves: actuators and valves are used to adjust equipment during the process according to commands from PLC or DCS systems to maintain target states and production requirements.

Computers and servers: Computers and servers are used to host software and databases for DCS systems, providing functions such as data storage, alarm management, historical recording, and user interface.

Communication equipment: Communication equipment is used to connect various components of the DCS system for data transmission and real-time communication, including communication protocols such as Ethernet, Profibus, Modbus, etc.

Operation interface: The operation interface is usually a human-machine interface (HMI) or monitoring system, which provides a way for operators to interact with the DCS system, allowing them to monitor processes, set parameters, and respond to alarms.

Control room equipment: Control room equipment includes consoles, displays, keyboards, and mice, used for the operator's work environment to facilitate monitoring and control of industrial processes.

Network equipment: Network equipment is used to connect various components of the DCS system to achieve data communication and remote access, ensuring the reliability and security of the system.

Power supply and backup system: The power supply and backup system are used to ensure the availability of the DCS system, including UPS (Uninterruptible Power Supply) and backup power supply equipment.

Safety equipment: Safety equipment includes explosion-proof boxes, emergency stop buttons, and safety sensors to ensure the safety of industrial processes.

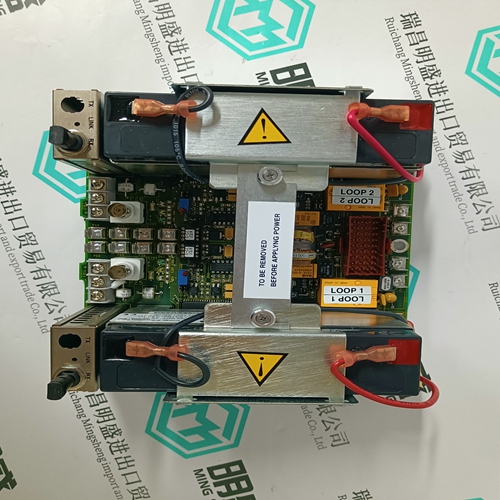

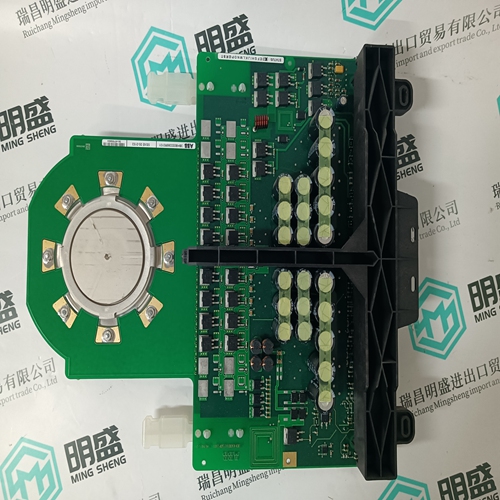

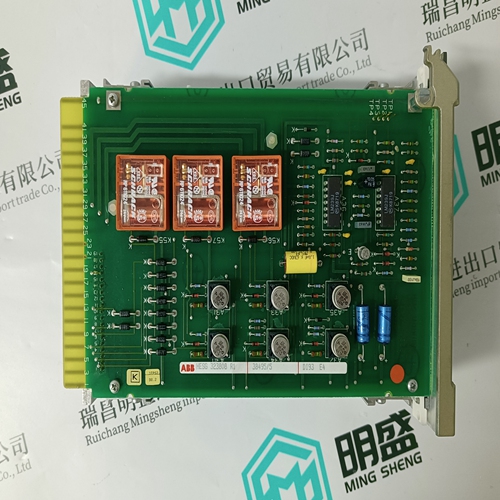

Product image

Related products:

Nikon 4S017-615 Control Pulse Module