Home > Product > Robot control system > NIKON D300 Industrial Control DCS System

NIKON D300 Industrial Control DCS System

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NIKOND300Industrial Control DCS System

- Get the latest price:Click to consult

NIKON D300 Industrial Control DCS System

Product Details Introduction

The Distributed Control System (DCS) is an automation system used for monitoring, controlling, and managing industrial processes and equipment. It has a distributed architecture that allows multiple controllers and operating stations to work together in industrial production processes. The following are some main features and functions of the industrial control DCS system:

Distributed architecture: The industrial control DCS system adopts a distributed architecture, which includes multiple controllers, operation stations, and input/output modules, which are distributed throughout the entire industrial system.

Real time control: The system provides real-time control capabilities, enabling real-time monitoring and control of parameters and equipment status in industrial processes.

Multilevel control: DCS systems typically support multi-level control strategies, including basic PID control, advanced control, optimization control, etc., to improve production efficiency and quality.

Distributed input/output: Input/output modules are usually distributed throughout the factory to reduce wiring harness costs and improve reliability.

Data collection and storage: The DCS system can collect a large amount of data and store it in a historical database for analysis, fault diagnosis, and report generation.

Human machine interface: The operation station provides an intuitive human-machine interface, allowing operators to monitor and control industrial processes for real-time decision-making.

Communication capability: The DCS system supports multiple communication protocols to facilitate data exchange and connection between devices to higher-level control systems.

Security: Systems typically have security functions, including user authentication, access control, emergency stop, etc., to ensure the safety of equipment and personnel.

Fault tolerance: DCS systems typically have redundancy and backup mechanisms to prevent production interruption caused by a single point of system failure.

Scalability: The system has good scalability and can add more controllers, input/output modules, and operation stations as needed to adapt to changes in production scale.

Application field: DCS systems are widely used in industrial fields, including chemical, petroleum and natural gas, power, manufacturing, water treatment, food and beverage, etc., to achieve automation and control of complex industrial processes.

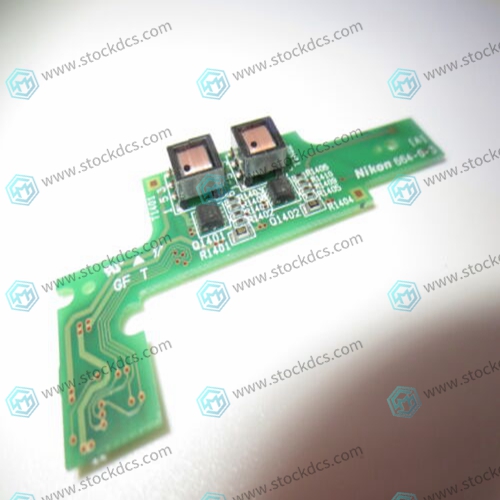

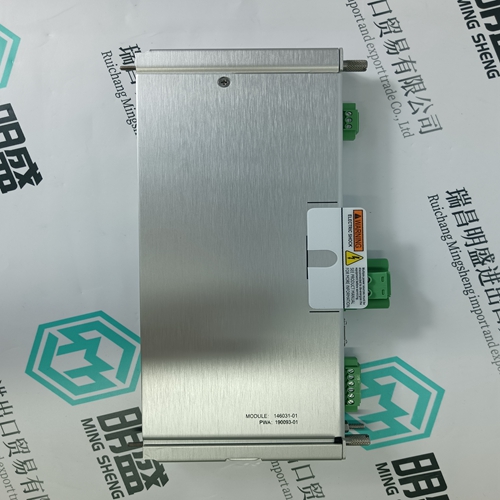

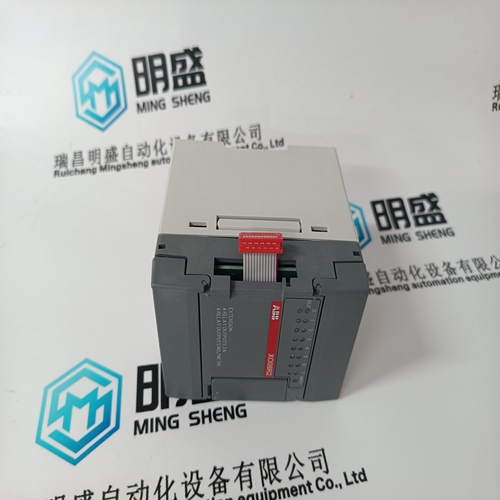

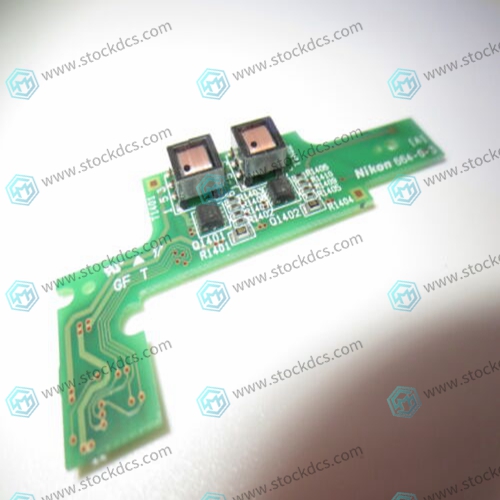

Product image

Related products:

Nikon 4S017-615 Control Pulse Module