Home > Product > Robot control system > Nikon 4S014-077 Industrial Control DCS System

Nikon 4S014-077 Industrial Control DCS System

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:Nikon4S014-077Industrial Control DCS System

- Get the latest price:Click to consult

Nikon 4S014-077 Industrial Control DCS System

Product Details Introduction

Industrial Control Systems (ICS) are automation systems used to monitor and control industrial processes. One of the main types is Distributed Control System (DCS). DCS system is a control and monitoring system specifically designed for industrial applications, typically including the following key features:

Distributed architecture: The DCS system adopts a distributed architecture, which disperses control and monitoring functions among multiple controllers, servers, and workstations. This distributed structure helps to improve the reliability and fault tolerance of the system.

Controller: DCS systems typically include multiple controllers used to execute control logic and operational processes. These controllers are distributed across different control units and can coordinate multiple operations simultaneously.

Communication network: The DCS system uses a highly reliable communication network to connect various controllers, sensors, actuators, and operating stations. These networks typically have low latency, high bandwidth, and redundancy to ensure timely data transmission and control operations.

Graphical User Interface: The DCS system provides an intuitive graphical user interface (HMI) that operators can use to monitor processes, perform control operations, and view real-time data.

Data collection and analysis: The DCS system can collect a large amount of real-time data, analyze the process, and generate reports to help operators and engineers make decisions.

Automation control: The DCS system allows for automatic control of processes, including feedback control, PID control, and logic control, to ensure that the process operates within the set parameter range.

Safety: DCS systems emphasize safety, including protection of equipment, data, and systems to reduce potential risks.

Scalability: These systems typically have a certain degree of scalability, allowing for the addition of new controllers, sensors, and actuators to adapt to constantly changing needs.

Alarm and event management: The DCS system can monitor abnormal situations during the process and generate alarms to notify operators or engineers to take necessary measures.

Historical data storage: DCS systems typically record historical data for performance analysis, troubleshooting, and compliance report generation.

Engineering tools: In order to configure, program, and maintain DCS systems, specific engineering tools are typically used, allowing engineers to create control logic and parameter configurations.

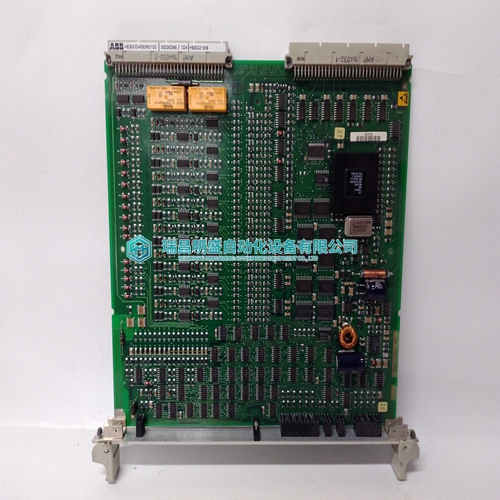

Product image

Related products:

Nikon 4S017-615 Control Pulse Module