Home > Product > Robot control system > Nikon 2S013-076 wafer prealigner

Nikon 2S013-076 wafer prealigner

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:Nikon2S013-076wafer prealigner

- Get the latest price:Click to consult

Nikon 2S013-076 wafer prealigner

Product Details Introduction

The Nikon 2S013-076 Wafer Pre Aligner is a key component in semiconductor manufacturing equipment, used to automatically align the position and direction of wafers (usually silicon wafers) for subsequent manufacturing processes such as photolithography, ion implantation, chemical vapor deposition, etc. This process is crucial for ensuring the accuracy and quality of semiconductor devices. Here are some main features and applications of the Nikon 2S013-076 wafer prealigner:

Precise positioning: The Nikon 2S013-076 wafer pre aligner can detect the marks or features on the wafer, and then adjust the position and rotation angle of the wafer to ensure that the wafer is aligned with the standard position and direction of the manufacturing equipment.

Improve automation: It helps automate semiconductor production processes and reduces the need for human intervention. This helps to improve production efficiency and reduce operational errors.

Improving production throughput: By quickly and accurately aligning wafers, prealigners help improve the production throughput of manufacturing equipment, thereby reducing production costs.

Reduce device wear: By avoiding unnecessary contact between wafers and devices, the Nikon 2S013-076 wafer aligner can extend device life and reduce maintenance costs.

Suitable for various wafer sizes: Many prealigners can adapt to different sizes and types of wafers, ranging from 200mm to 300mm and larger.

Integration into the manufacturing process: The prealigner is usually a part of semiconductor equipment, seamlessly integrated with other manufacturing equipment (such as lithography machines, etching machines, etc.) to ensure process continuity.

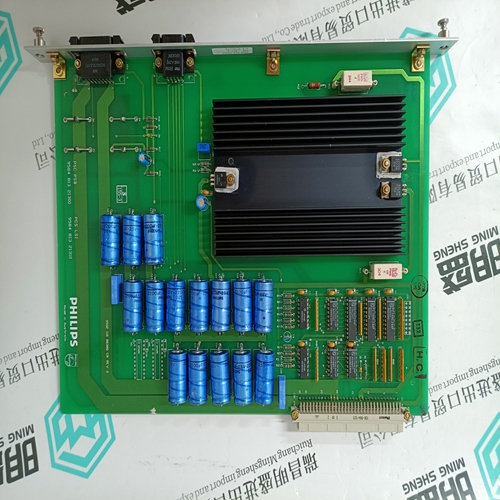

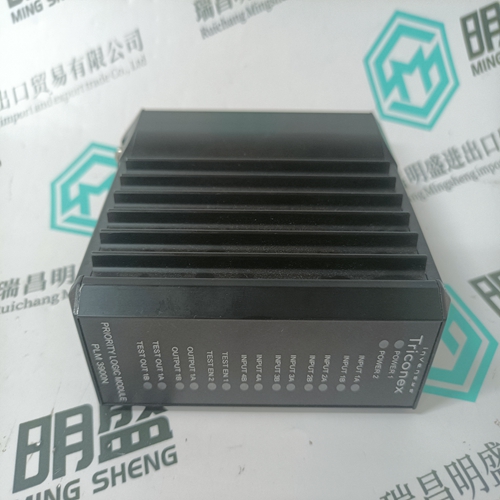

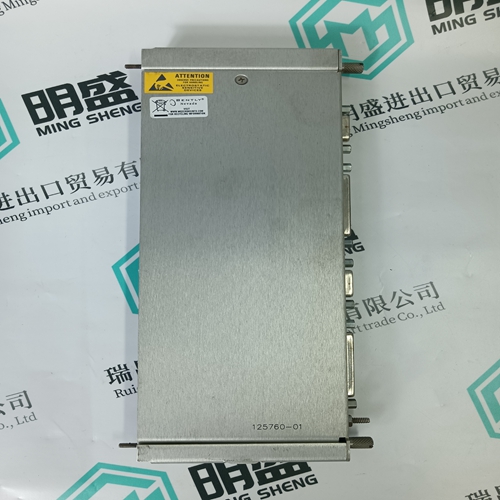

Product image

Related products:

Nikon 4S017-615 Control Pulse Module

Nikon 4S020-160 Industrial Control Module

NIKON 4S019-426-1 Control Main Board Module