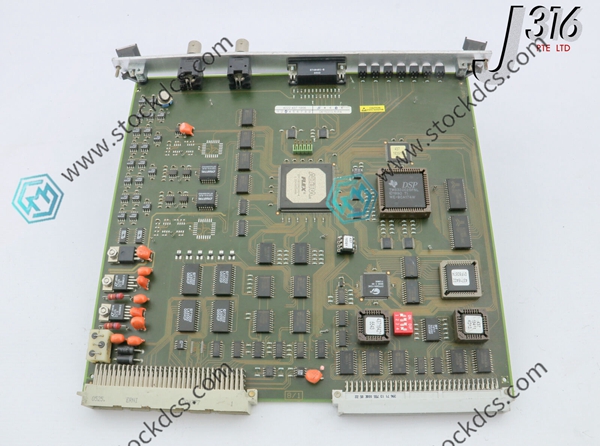

Home > Product > Robot control system > ASML 4022.437.1856 Printed Circuit Board

ASML 4022.437.1856 Printed Circuit Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:4022.437.1856

- Get the latest price:Click to consult

ASML 4022.437.1856 Printed Circuit Board

Product Details Introduction

Printed Circuit Board (PCB) is a fundamental component used to support and connect electronic components. PCB is usually made of insulating material, with conductive routes and connection points printed on it, so that electronic components can be installed and disassembled on it. PCB has been widely used in various electronic equipment, including computers, mobile phones, televisions, household appliances, and industrial control systems.

The manufacturing of PCBs typically involves the following steps:

Raw material selection: Choose appropriate insulation substrates, such as glass fiber reinforced resin (FR4), and copper foil for manufacturing conductive layers.

Structure planning: Creating the structure of a circuit board through computer-aided design (CAD) software, including affirming the status and connection form of electronic components.

Printing: Using chemical decay or machine processing techniques to print circuit patterns onto copper foil.

Drilling: In order to install and disassemble components and connecting wires, it is necessary to drill holes on the PCB.

Assembly and disassembly of components: Use SMT or pull-out components to assemble and disassemble electronic components onto a PCB.

Welding: Connect the components to the PCB through welding techniques to ensure electrical connection.

Attempt: Stop the effectiveness of the circuit board to ensure that they rest normally.

Final assembly: Assemble and disassemble the PCB together with other electronic components (such as screens, batteries, etc.) into a complete electronic device.

Product image

Related products:

ASML 4022.470.8125 Power Modul

ASML 4022.472.5847 Laser Modul

其他网站链接