Home > Product > Robot control system > ASML 4022.471.4042 PCB Assembly

ASML 4022.471.4042 PCB Assembly

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:4022.471.4042

- Get the latest price:Click to consult

ASML 4022.471.4042 PCB Assembly

Product Details Introduction

ASML 4022.471.4042 PCB Assembly refers to the assembly and disassembly of electronic components (such as integrated circuits, resistors, capacitors, interconnectors, etc.) onto a printed circuit board (PCB), and the process of soldering, connecting, and attempting is stopped. PCB assembly is a crucial component of modern electronic equipment and systems, transforming circuit boards into a fully functional electronic system. The following are some important aspects of the ASML 4022.471.4042 PCB assembly:

Component installation and disassembly: The first step of ASML 4022.471.4042 PCB assembly is to accurately install and disassemble various electronic components onto the printed circuit board. These components can be installed and disassembled using Surface Mount Technology (SMT) or Through Hole Technology (THT) techniques, depending on the component category and PCB plan.

Soldering: Once components are installed and removed on the ASML 4022.471.4042 PCB, they need to be soldered onto the wiring to ensure electrical connection. This usually affects the application of solder, solder paste, or other welding materials.

Connector and connector: The ASML 4022.471.4042 PCB assembly can include connectors and connectors for connecting other PCBs, cables, or external equipment to achieve system interconnection.

Power supply: The ASML 4022.471.4042 PCB assembly usually requires a power supply to ensure the normal operation of the components. This can affect the planning and connection of the power circuit.

Circuit attempt: After completing component installation, disassembly, and soldering, PCB assemblies usually need to stop circuit attempts to verify the effectiveness and functionality of the system. This includes connectivity attempts, efficacy attempts, and electrical parameter attempts.

Fixation and support: The ASML 4022.471.4042 PCB assembly can be fixed in the equipment and provides support and machine stability. This can include installation and disassembly inside the chassis or rack.

Anti static step: In PCB assemblies, anti static step is usually very important to avoid electrostatic discharge damaging electronic components.

Quality control: ASML 4022.471.4042 PCB assemblies usually require strict quality control to ensure the reliability and functionality of the product.

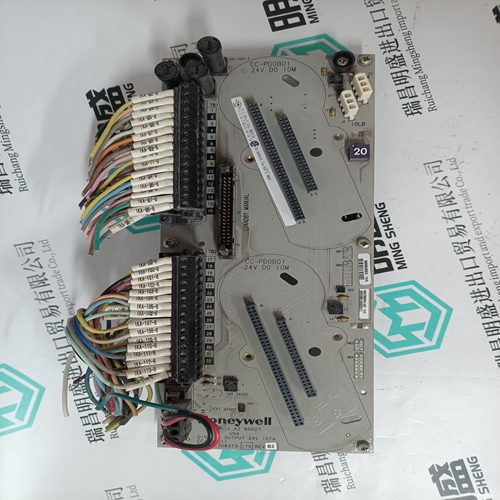

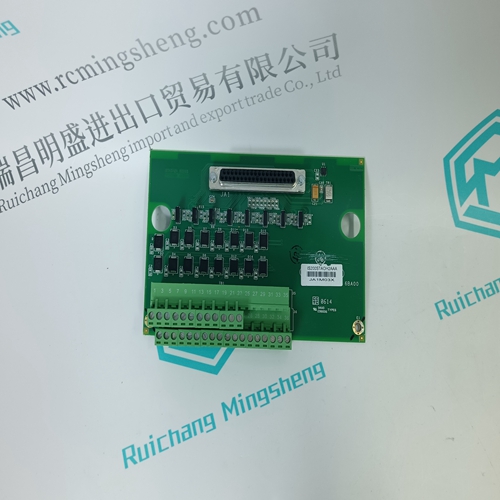

Product image

Related products:

ASML 4022.634.20691 Fiber Opti

ASML 4022-639-92101 Laser Lamp

其他网站链接