Home > Product > Servo control system > WOODWARD 8446-1019 Servo speed governor

WOODWARD 8446-1019 Servo speed governor

- Product ID: 8446-1019

- Brand: WOODWARD

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:WOODWARD8446-1019Servo speed governor

- Get the latest price:Click to consult

WOODWARD 8446-1019 Servo speed governor

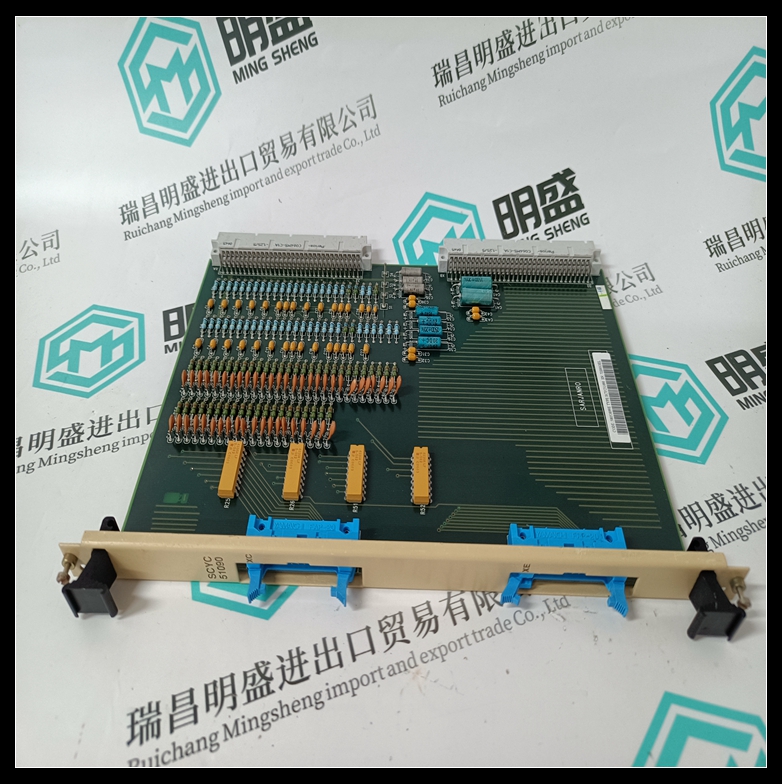

Type J and K thermocouples must conform to the common commercial specifications published in the Annual Book of ASTM Standards with voltage predictions in line with N.I.S.T. Monograph 175 or ITS-90.Open thermocouple detection: Fail Low and Fail High depending on P/N Cold Junction: AD590 Resolution: 12 bits Temp Coefficient (ppm/ C): 235 Accuracy: 1% at 25 °C (factory calibrated) Input Impedance: 2.0 MΩ Power Supply Input: 18 to 32 Vdc Power Required: 2.4 W at 24 Vdc

Install the LINKnet 6CH TC Module on the DIN rail and connect to the appropriate LINKnet network and 24 Vdc power. Wire the thermocouple connection per Figure 11-10. Set module address one’s and ten’s rotary switches per application setup. The LINKnet system accommodates hot-replacement of faulty nodes. When replacing a node, the network cable connections must remain intact. A faulty node can be removed from the network by pulling both terminal blocks out of their headers, and removing the node from the DIN rail. The address switches of the replacement node should be set to match those of the faulty node. The replacement node can then be mounted on to the DIN rail, and the terminal blocks pushed into the headers. It is then necessary to reset the node through the application program to reinitiate communications with the LINKnet controller module and to clear the "no message" fault.

The module receives information

from thermocouples, which can be either J or K type. The type is selected in the application program. It also has an AD592 ambient temperature sensor mounted on the module for cold junction temperature sensing. The cold junction compensation is performed in software. There is a fail high and a fail low version of the module, selected by jumpers on the board, which allow the input channels to be pulled high or low on an open input. Each input is multiplexed to a voltage-to-frequency converter. The module processor reads the period of this signal and converts it to a count, which it transmits through the transceiver to the LINKnet controller module. See Figure 11-11 for block diagram of the thermocouple input module.The fault LED denotes the status of the module processor, and will be off during normal operation. If the fault LED is on or is blinking, and cycling power to the module does not change it, then the I/O module should be replaced.

The module address circuit reads

the selected module address from the rotary switches on each node. This address should correspond to the address of the I/O module hardware in the application program. If these rotary switches are set incorrectly, the node will not communicate with the LINKnet controller module, and a "no message" fault will be annunciated through the application program. If two nodes are set to the same address, an "address" fault will be annunciated through the application program, and both nodes will not function. If the node address switches are changed, power to the module must be cycled before it will read the new module address and change its communication accordingly. A "type" fault is annunciated through the application program when the wrong module type is installed at a given address. For example, installing a thermocouple module in place of an RTD module generates a type fault. If an output node receives data intended for a different module type, it will not update its outputs, and will set them to the "off" state when its watchdog timer times out. No message faults, address faults, and type faults are non-latching. When these faults occur for an input module, the application program will give default values for each channel.

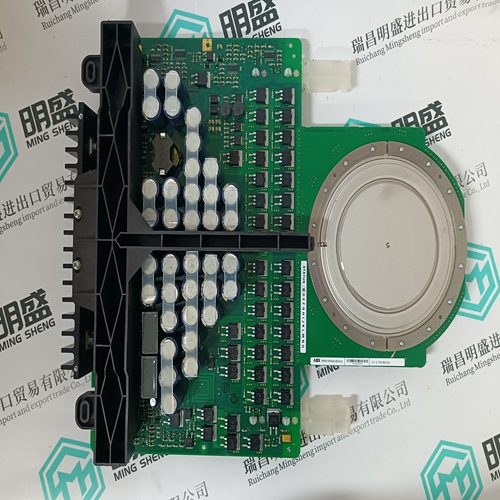

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.