Home > Product > Robot control system > EMERSON A6110 programmable controller

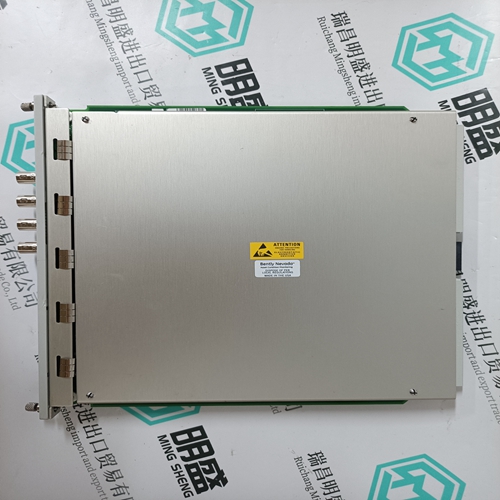

EMERSON A6110 programmable controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:A6110

- Get the latest price:Click to consult

EMERSON A6110 programmable controller

Product Details Introduction

Programmable Logic Controller (PLC) is a special computer used in automation control systems and is widely used in industrial control and automation fields. The functions of EMERSON A6110 PLC mainly include the following aspects:

1. Logic control function:

Program running: EMERSON A6110 PLC can execute user-edited control programs, which are usually expressed in ladder diagrams or other programming languages. The order of program execution is determined by a user-edited logic control algorithm.

Logic operations: PLC supports logic operations, such as AND, OR, NOT, etc., to achieve complex logic control functions.

Conditional branch: PLC has the ability to conditionally branch and select different paths according to the status of the input signal.

2. Input/Input Mastery:

Input module: PLC receives input signals from external sensors, switches, etc. through the input module to monitor system conditions.

Input module: PLC controls input devices such as actuators, motors, and valves through the input module to perform corresponding actions.

Real-time monitoring: PLC monitors the input status in real time and updates the input status when necessary to maintain the correct operation of the system under specific conditions.

3. Activity mastery:

Motor control: PLC can control servo motors, stepping motors, etc., to achieve accurate movement control of mechanical equipment.

Speed and position control: PLC can accurately control the speed and position of sports equipment to meet different sports needs.

4. Communication function:

Communication protocol support: PLC supports various communication protocols, such as Modbus, Profibus, Ethernet, etc., for data exchange with other devices.

Remote monitoring and control: PLC has remote communication functions, which can monitor and control remote equipment through the network or other communication means.

5. Timing and counting functions:

Timer: PLC has a built-in timer function that can perform timing control tasks, such as timing drives and running equipment.

Counter: The PLC has a built-in counter that can be used to count specific events, such as the number of products in the production process.

6. Fault diagnosis, treatment and alarm:

Fault detection: PLC has fault detection function, which can monitor abnormal situations in the system, such as sensor faults, communication faults, etc.

Alarm generation: PLC can generate alarm signals and take corresponding steps, such as running equipment or triggering maintenance processes.

7. Data processing and storage:

Data processing: PLC has certain data processing capabilities and can perform mathematical operations, logical operations, etc.

Data storage: PLC can save runtime data, equipment status information, etc. for subsequent monitoring and analysis.

8. User interface:

Human Machine Interface (HMI): Some PLCs integrate HMI, allowing operators to monitor and operate the system intuitively.

Reports and logs: PLC can generate reports and logs to record the operation history, events and fault information of the system.

9. No Programmability and Flexibility:

User programming: PLC has user programming functions, and users can edit control programs using specific programming languages.

Flexible configuration: PLC has flexible configuration options, and users can configure input/output modules, communication interfaces, etc. according to actual application needs.

The functions of EMERSON A6110 PLC make it an important part of industrial automation and control systems, and it is widely used in manufacturing, energy, transportation and other fields.

Product image

Related products:

EMERSON A6740-12 Output Relay Module

EMERSON A6210 Shaft Vibration Monitoring

其他网站链接

| 105-040300-01 | HZ170A601 | BRC-200 |

| 105-090301-01 | SS7B481MDO | BRC-300 |

| 105-524002-01 | SSM-48-F | BUS MONITOR |

| 105-032002-01 | HM706A6 | IEFAN01 |

| 105-641001-01 | SL5C-101 | IEMMU21 |