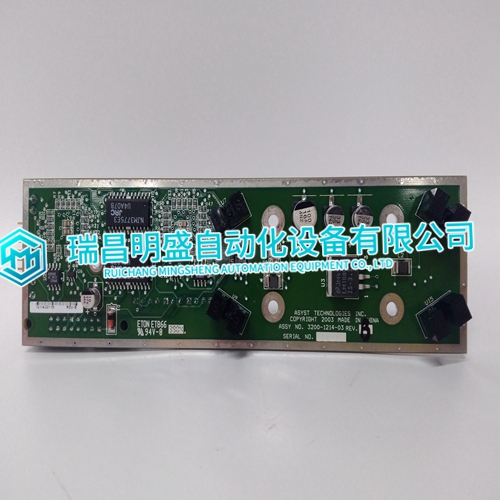

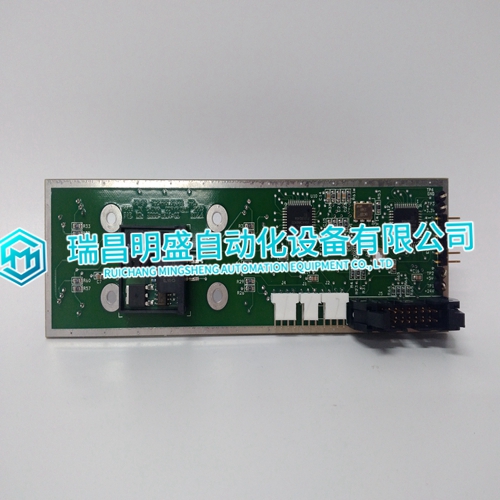

Home > Product > Robot control system > ASYST 3200-1214-03 Output module

ASYST 3200-1214-03 Output module

- Product ID: 3200-1214-03

- Brand: ASYST

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ASYST3200-1214-03Output module

- Get the latest price:Click to consult

ASYST 3200-1214-03 Output module

Discrete connection that is actually an input, but is shown with the Driver (-) and (+) connections. This signal should be connected to the current sense resistor on the external solenoid driver. The external solenoid driver is a transistor drive circuit that is mounted off of the module because of the heat sink requirements. This input is used to check the current being passed through the solenoid, for over and under current conditions.This signal should be connected to the (-) input of the #1 external solenoid driver. See diagram 1.0 for the external solenoid driver wiring connections This signal should be connected to the (+) input of the #1 external solenoid driver. See diagram 1.0 for the external solenoid driver wiring connections.Discrete connection that is actually an input, but is shown with the Driver (-) and (+) connections. This signal should be connected to the current sense resistor on the external solenoid driver. The external solenoid driver is a transistor drive circuit that is mounted off of the module because of the heat sink requirements. This input is used to check the current being passed through the solenoid, for over and under current conditions.This signal should be connected to the (-) input of the #2 external solenoid driver. See diagram 1.0 for the external solenoid driver wiring connections.

Current Faults Cleared

This output is used to indicate when all of the faults have cleared and the current to the solenoids are in their respective operating ranges. This output can be connected directly to a discrete input or to a relay, and can be used to turn off the Solenoid Failure Override input.Field Termination Modules (FTM) are used to connect field wiring to the front of the MicroNet control’s I/O Modules. They connect to the subminiature D-type connectors on the front of the I/O modules and provide cage-clamp terminal connection points for field wiring. They also provide shield termination and EMI protection. All FTMs can be mounted on 35 mm DIN Rails and take the place of interposing terminal blocks to field wiring. The cage-clamp terminals on the FTMs and relay modules accept a maximum of one #12 AWG wire or two #18 AWG wires. Field wiring hookup is performed by stripping the wire back 0.312 inches (8 mm), inserting into the cage clamp and tightening the screw.The 34Ch HDVIM FTM is used with the 34Ch HDVIM Module (see Chapter 9 MicroNet module information and Appendix A for FTM part number). One MicroNet High Density Analog/Discrete cable is use to connect the FTM with the 34Ch HDVIM Module (see Appendix A for part numbers). There are nine +24 Vdc connections available for sourcing 4-20 mA inputs. Each connection is protected with a 0.1 A fuse.

Replacing a Fuse on the Field Termination Module (FTM)

1. Verify that the condition that caused the fuse to blow has been corrected. If power has not been removed from the control system, power will be active at the module and also at the FTM. Shorting of protected circuitry could cause a control system shutdown. 2. Remove the FTM cover carefully, to prevent contact with any FTM circuitry under the cover. To remove the FTM cover, pinch the retaining barb and lift the cover. 3. Locate and replace the fuse with another fuse of the same size, type, and rating, See Figure 13-4 for channel fuse location. 4. Replace the FTM cover. Two 24/8 Analog FTMs are used with the 24/8 Analog Modules (see Chapter 9 MicroNet module information and Appendix A for FTM part number). One MicroNet High Density Analog/Discrete cable is used to connect each FTM to the 24/8 Analog Module (see Appendix A for part numbers). There are twelve +24 Vdc connections available for sourcing 4–20 mA inputs. Each connection is protected with a 0.1 A fuse

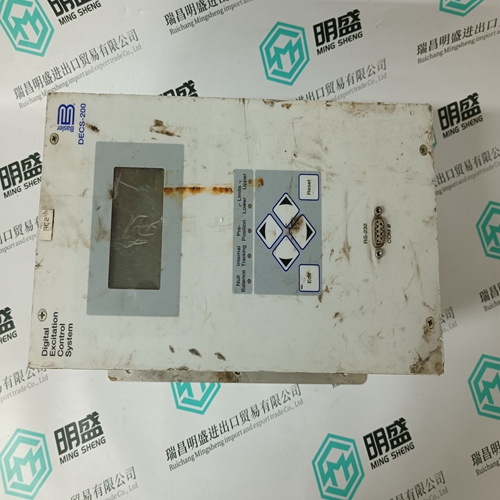

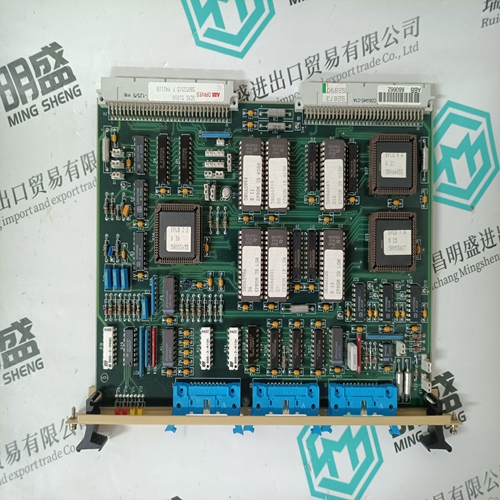

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.