Home > Product > Robot control system > PMV F5-MEC valve positioner

PMV F5-MEC valve positioner

- Product ID: PMV F5-MEC

- Brand: PMV

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PMV F5-MECvalve positioner

- Get the latest price:Click to consult

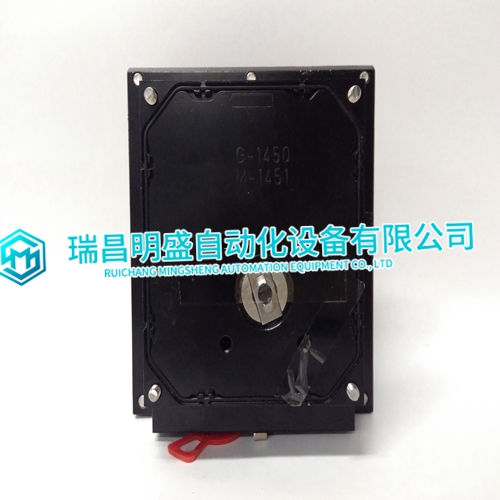

PMV F5-MEC valve positioner

Actuator Install the actuator solidly, and install a linkage with the correct configuration to provide an almost linear relationship between change of actuator position and change in engine power output. In most cases use about 2/3 of the actuator rotation between minimum and maximum fuel. The engine fuel control usually provides the minimum and maximum stops. The minimum and maximum stops on the actuator may be used, if necessary (see Figure 2-1). If the actuator is controlling the speed-setting shaft of a mechanical governor, use the actuator stops to limit the travel of the linkage. Set the minimum stop for 5% below rated speed at no load, and set the maximum stop for rated speed plus 3% more than the droop of the governor. The actuator is designed to operated in ambient temperatures of –40 to +82 °C (–40 to +180 °F). Installation should avoid sources of excessive heat.

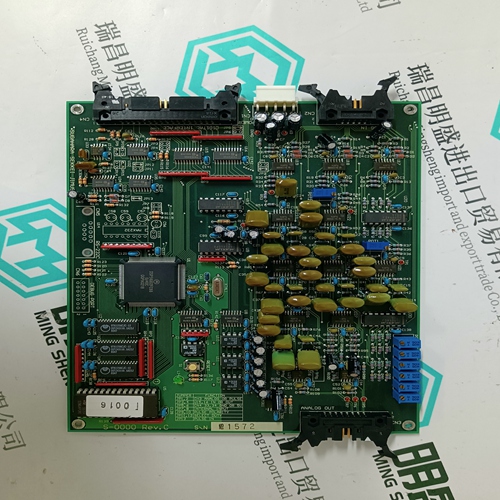

Wiring Diagram Notes

1. Shielded wires to be twisted pairs or twisted 3-conductor, grounded at one end only. 2. 4 or 2 mm² (12 or 14 AWG) stranded wire, must be as short as possible. Total of distance from battery to control, and from control to actuator, to be as short as possible (see maximum length in chart). 3. See EPG Models above for source voltages. 4. Open for minimum fuel. Do not use either the minimum fuel option, or disconnect the actuator leads, or disconnect the power to the control as part of any emergency stop sequence. 5. For positive ground systems, switch and fuse to be located in series with battery (–) and terminal 2. Positive (+) terminal becomes chassis ground. Leads from battery to terminals 1 and 2 must be direct and not pass through distribution points. 6. Approximate speed change with trim potentiometer: ±2.5% using a 1 kΩ potentiometer ±5% using a 2 kΩ potentiometer 7. About one second ramp time per 50 µF. Capacitor specification: 200 µF maximum, 15 W minimum, less than 30 µAdc leakage current over temperature range.

Polarity not important.

11. With a balanced load and unity power factor (PF=1), the current transformer should be wired in the correct potential leg, and must be phased at the control so the potential at terminal 9 to 10 is in phase with the CT from terminal 11 to 12. 12. Power source current transformers should be sized to produce a 5 A secondary current, with maximum generator current. CT burden is essentially 0 VA. 13. Absolute minimum signal must be 95 Vrms. Absolute maximum signal must be 260 Vrms. Potential transformer burden is 20 VA. 14. This control contains an internal current transformer. This transformer must be connected across the power source transformer whenever the unit is running to prevent lethal high voltage from developing on leads to these terminals. 15. On systems without a neutral, the voltage at terminal 9 to 10 is 1.73 times N2/N1 times the line-to-line voltage.

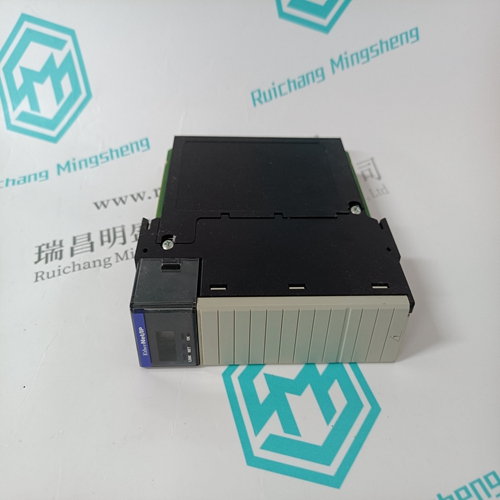

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.