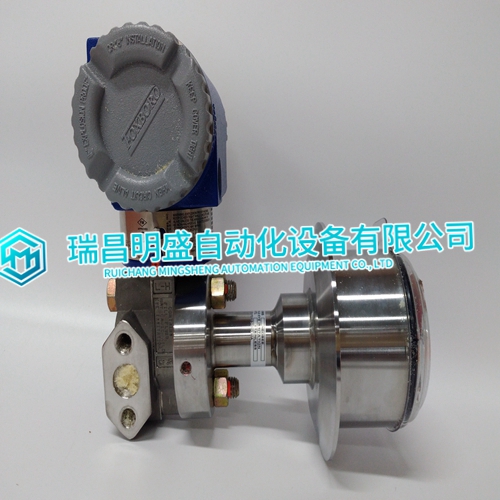

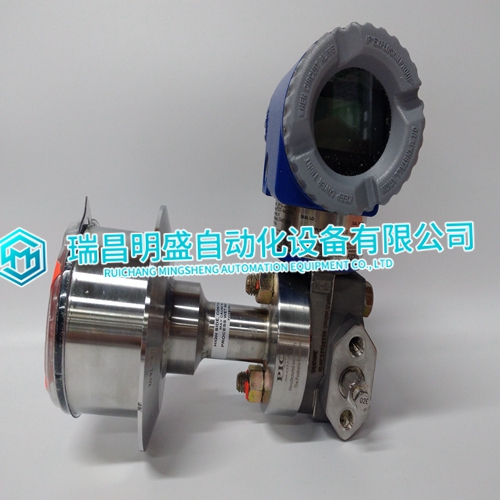

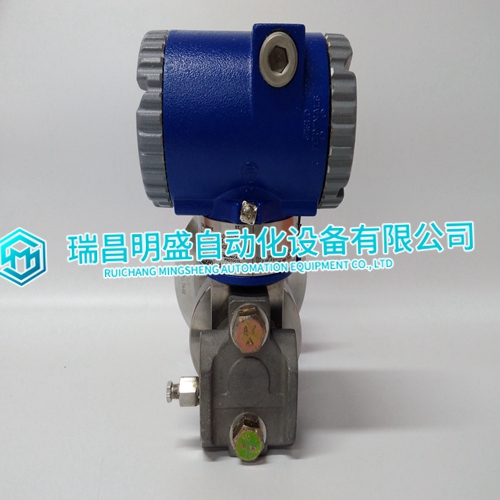

Home > Product > DCS control system > IDP10-AF1C01F Pressure transmitter

IDP10-AF1C01F Pressure transmitter

- Product ID: IDP10-AF1C01F

- Brand: FOXBORO

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:IDP10-AF1C01FPressure transmitter

- Get the latest price:Click to consult

IDP10-AF1C01F Pressure transmitter

MPU voltage between terminals 5 and 6 at least 1.5 Vrms while cranking? (For small gears, it may be necessary to decrease the MPU clearance). Do not decrease below 0.25 mm (.010 inches). • Actuator should go to maximum fuel position when the starter turns engine or turbine. (If applicable, Start Fuel Limit must be fully clockwise.) • When the engine or turbine starts and comes to speed, the actuator arm should move toward minimum-fuel position. 11. Adjust the GAIN pot to the stable region between low-frequency and highfrequency oscillation. 12. If there is a low-frequency oscillation which does not stop when the GAIN pot is adjusted, turn the STABILITY pot slightly clockwise and try the GAIN pot adjustment again. Continue adjusting the STABILITY pot slightly clockwise, then readjusting the GAIN pot, until the engine runs at a steady speed. If there is a high-frequency oscillation which will not stop, even when the GAIN pot is fully counterclockwise, adjust the STABILITY pot slightly counterclockwise until the high-frequency oscillation stops.

Speed Settings

13. Adjust the RATED SPEED pot for the desired rated speed. 14. Set the IDLE SPEED pot for the desired idle speed. 15. Close the IDLE/RATED switch. 16. Adjust transient response. Simulate a transient by manually bumping the linkage. To decrease settling time (may increase ringing) after a transient, turn the GAIN pot clockwise slightly, then turn the STABILITY pot as required to eliminate oscillation and to obtain desired response. Repeat if necessary To decrease ringing (will increase settling time) after a transient, turn the GAIN pot counterclockwise slightly, then turn the STABILITY pot as required to eliminate oscillation and obtain desired response. Repeat if necessary. 17. Select alternate dynamics and alternate fuel, if applicable. Repeat this step as necessary. This completes the check of units without droop. For units with droop, do the following additional steps.

Droop Adjustment (only for units with droop)

Example 1: The generator set is a 60 Hz unit with an isolated load. If the desired droop is 5% and the generator set can be run at 100% load, then the speed at full load would be 57 Hz. Example 2: It is again desired to set the droop of the same generator set to 5%, but this time the generator set cannot be run at 100% load. The generator set is therefore run at 50% load and the speed (in step 3) would be 58.5 Hz. Example 3: The generator set is a 60 Hz unit that will be paralleled with an infinite bus. If the desired droop is 5% and the generator set can be run at 100% load, the speed at which the generator is run (in step 2) would be 63 Hz.

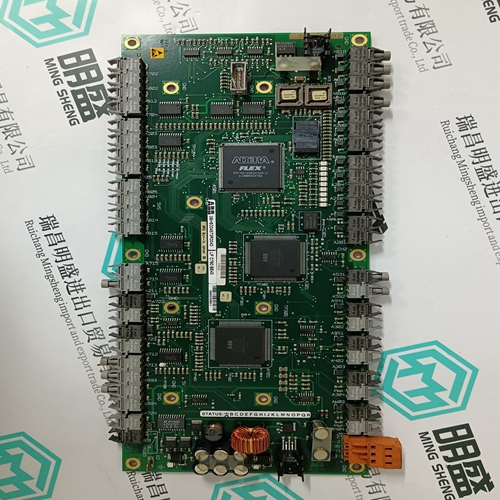

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.