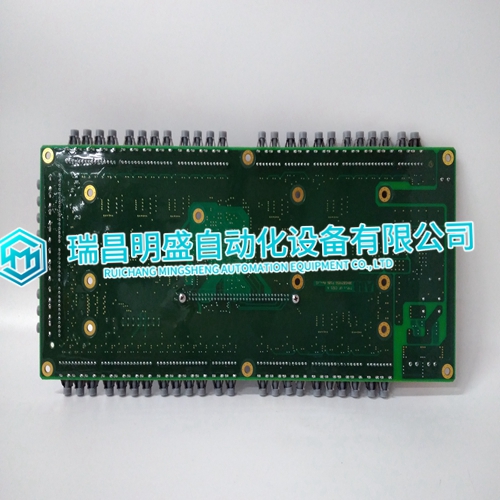

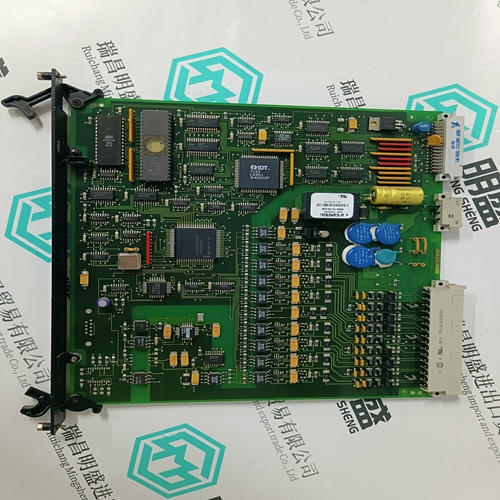

Home > Product > DCS control system > UFC921A101 3BHE024855R0101 Analog output card

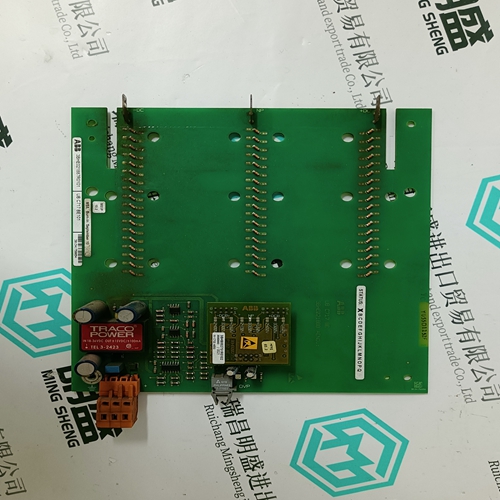

UFC921A101 3BHE024855R0101 Analog output card

- Product ID: UFC921A101 3BHE024855R0101

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:UFC921A1013BHE024855R0101Analog output card

- Get the latest price:Click to consult

UFC921A101 3BHE024855R0101 Analog output card

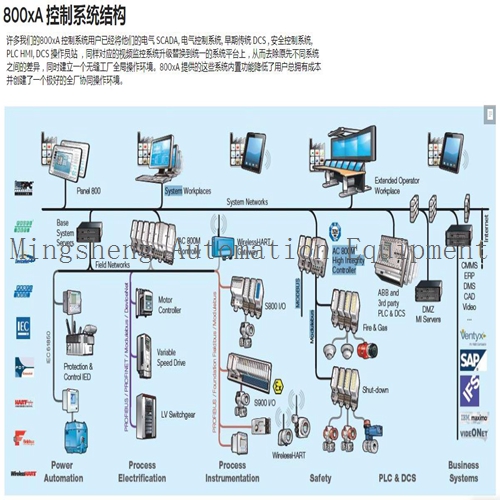

Every effort has been made to include specific safety-related procedures in this manual using the symbols described above. However, operating personnel are expected to follow all generally accepted safety procedures. Safety procedures should be communicated to all personnel who are liable to operate the equipment described in this manual. Vibro-Meter does not accept any liability for injury or material damage caused by failure to obey any safety-related instructions or due to any modification, transformation or repair carried out on the equipment without written permission from Vibro-Meter. Any modification, transformation or repair carried out on the equipment without written permission from Vibro-Meter will invalidate any warranty The purpose of this document is to describe the use of a VM600 machinery protection system (MPS) in a functional safety context as defined by IEC 61508 and ISO 13849-1.The following symbol introduces directives, procedures or precautionary measures which must be executed or followed.The VM600 system as described in this document is certified by TÜV® NORD to the following levels: • IEC 61508 Safety Integrated Level 1 • ISO 13849-1 performance level C.

VM600 in a Safety Related System

When a VM600 is part of a safety related system (SRS), certain configuration restrictions must be applied. In particular: • The output relays must be configured as de-energized to trip. Specifically: • the relay is energized when the monitored levels are within their specified tolerances • the relay is de-energized to indicate an alarm. • The use of the VM function danger bypass is not allowed. • The use of the VM function trip multiply is not allowed. • The alarm must be defined as ‘latching’.The VM600 machinery protection system (MPS) can be configured in many different arrangements. These configurations are described in more detail in the hardware manual (see 1.5 - Applicable Documents). For example, the VM600 can be used to protect rotating machines in a safety related system.

Configuring the System

It is important that the levels (vibration and so on) are adjusted to suit the system under protection and that a manual verification is made of the parameters that are uploaded to the system (MPC4 card). Note that the procedures described should only be performed by competent and authorized personnel following the plant specific guidelines in force at the installation site. 3.9.1 Define the levels The choice of alarm levels must be made in consultation with the site manager. It is the end user’s responsibility to ensure that the alarm levels are appropriate for the particular system being protected. The levels are defined using the MPS1 software (supplied) or the MPS2 software (optional). Please refer to the appropriate documentation for complete information.

The main products

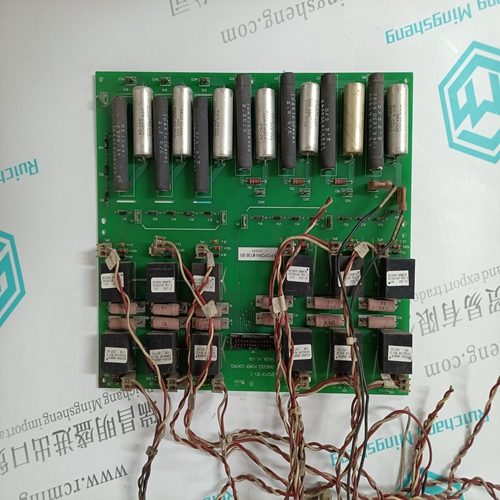

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.