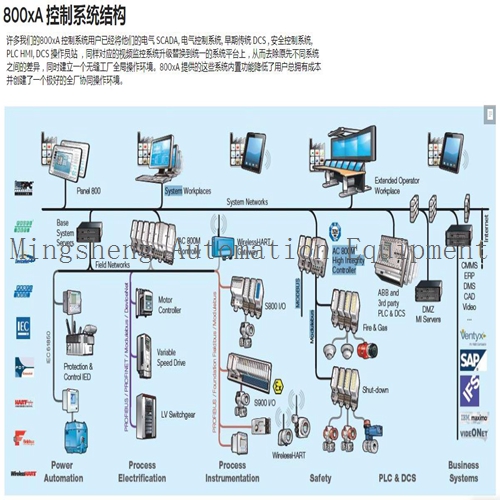

Home > Product > DCS control system > UNS0119A-P,V101 3BHE029153R0101 Analog card

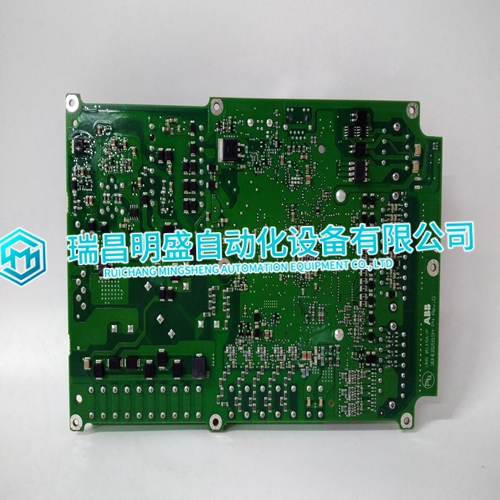

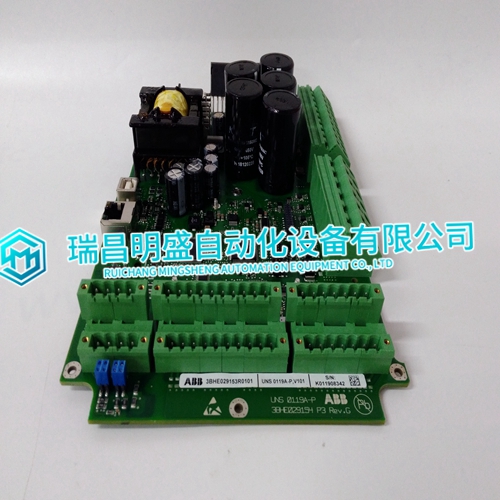

UNS0119A-P,V101 3BHE029153R0101 Analog card

- Product ID: UNS0119A-P,V101 3BHE029153R0101

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:UNS0119A-PV1013BHE029153R0101Analog card

- Get the latest price:Click to consult

UNS0119A-P,V101 3BHE029153R0101 Analog card

Define the alarm outputs Any relay on the MPC4 or RLC16 cards can be configured to provide the safety function. As previously noted, the alarms must be: • configured as ‘latching’ • de-energized to ‘trip’. 3.9.3 Upload the levels and configuration Once the system parameters have been correctly defined using the MPS software, the configuration for each MPC4 card must be uploaded to the card. This procedure is described in the MPS1 Software Manual MAMPS1-SW/E Whilst the actual upload of data is controlled by CRC verification and other techniques, in order to fulfil the IEC 61508 requirements a manual verification of this upload is required. The verification is made by downloading the configuration from the MPC4 card to the computer and comparing the data received with the original data uploaded to the card.• Use the Dump to File option to save the configuration as pc_card_1.csv. • Define a dummy rack using a Tag name from_sys_1. • Select this rack, connect to the MPC4 card concerned and read its configuration back to the computer. • Dump this file as sys_card_1.csv.

Guidelines for commissioning

Installing a VM 600 system is fully described in section 8 of the MPS Hardware Manual (Standard Version) MAMPS-HW/E.The system should be commissioned as an integral part of the overall SIS commissioning. INSTALLATION AND COMMISSIONING SHOULD ONLY BE PERFORMED BY COMPETENT AND AUTHORIZED PERSONNEL FOLLOWING THE PLANT SPECIFIC GUIDELINES IN FORCE AT THE INSTALLATION When the VM600 is taken offline, the attached system and equipment are no longer protected. Therefore, this procedure should only be undertaken by authorized personnel respecting the overall plant operations procedures. There should be no need to remove the equipment from site to perform these tests unless it is considered more convenient. The offline proof test reveals any dangerous faults that might not be detected in normal operation. For a VM600 system the proof test must be performed every 5 years or less.

Repair and Maintenance

If the VM600 system is under maintenance or repair, then the attached system and equipment may no longer be protected. Therefore, this procedure should only be undertaken by authorized personnel respecting the overall plant operations procedures.Reset 1- Reset the system by performing a cold start. That is, turn off and then turn on the rack. 2- Verify the safety relay status by performing a continuity test. 3- Observe the diagnostic LEDs and note any abnormalities. Refer to the MPS hardware manual for further information.

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.