Home > Product > DCS control system > IS200TREGH1BDB Distributed I/O Controller

IS200TREGH1BDB Distributed I/O Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:IS200TREGH1BDB

- Get the latest price:Click to consult

IS200TREGH1BDB Distributed I/O Controller

Product Details Introduction

GE IS200TREGH1BDB is a distributed I/O controller widely used in industrial automation and power systems. This controller is part of GE's Mark VIe control system, specifically designed for power plants and industrial process control applications. The following are some key features and application areas of this controller:

Key features

Distributed architecture: Supports distributed control system architecture, which can be deployed across a wide geographical range, improving system flexibility and scalability.

High reliability: sturdy design, able to operate stably in various industrial environments for a long time, and adapt to harsh working conditions.

Multi functional I/O support: Supports multiple input and output types, including analog input and output, digital input and output, and high-speed counters, to meet different application requirements.

Flexible configuration: Modular design allows users to flexibly configure I/O modules according to specific needs, meeting various complex control requirements.

Powerful communication capability: Supports multiple industrial communication protocols, including Ethernet, Modbus, Profibus, etc., making it easy to integrate with other control systems and devices.

Advanced diagnostic functions: provide real-time monitoring and diagnostic functions to help users quickly locate and solve faults, improve system reliability and operational efficiency.

application area

Power system control: widely used in power plant generator control, transformer control, busbar protection, and distribution system control to ensure the safe and stable operation of the power system.

Industrial automation: used for automation control of various industrial processes, including petrochemical, steel, papermaking, food and beverage industries, to improve production efficiency and product quality.

Renewable energy: In renewable energy projects such as wind and solar power, it is used to monitor and control power generation equipment to improve energy conversion efficiency.

Infrastructure management: applied to the automation control of infrastructure such as water treatment plants, sewage treatment plants, traffic management systems, etc., to improve management efficiency and service quality.

Application in product operation

In the field of product operations, the GE IS200TREGH1BDB distributed I/O controller can optimize operational processes in the following ways:

Improve system efficiency: Through flexible configuration and powerful communication capabilities, achieve efficient integration and coordinated operation of the system, and improve overall operational efficiency.

Reduce maintenance costs: Advanced diagnostic functions and highly reliable designs reduce equipment failure rates and downtime, lowering maintenance costs.

Enhance system flexibility: Distributed architecture and multifunctional I/O support facilitate system expansion and upgrading to meet constantly changing business needs.

Improve data accuracy: Real time monitoring and precise control ensure the accuracy and consistency of data during the production process, and improve product quality.

Maintenance and support

To ensure the reliable operation of the GE IS200TREGH1BDB distributed I/O controller throughout the product lifecycle, the following are some recommended maintenance and support strategies:

Regular inspection and maintenance: Conduct regular equipment inspections and maintenance to ensure the normal operation of the controller, and promptly identify and address potential issues.

Software and firmware updates: Keep the controller's software and firmware updated to ensure optimal performance and implementation of new features.

Technical training: Provide professional technical training for operators to ensure that they can correctly configure, operate, and maintain controllers.

Spare parts management: Establish a comprehensive spare parts management system to ensure quick replacement and repair in case of equipment failure, reducing downtime.

summary

The GE IS200TREGH1BDB distributed I/O controller is a powerful and highly reliable control device widely used in power systems and industrial automation fields. Through reasonable product operation and maintenance strategies, its value in practical applications can be maximized, and the efficiency, reliability, and operational performance of the system can be improved.

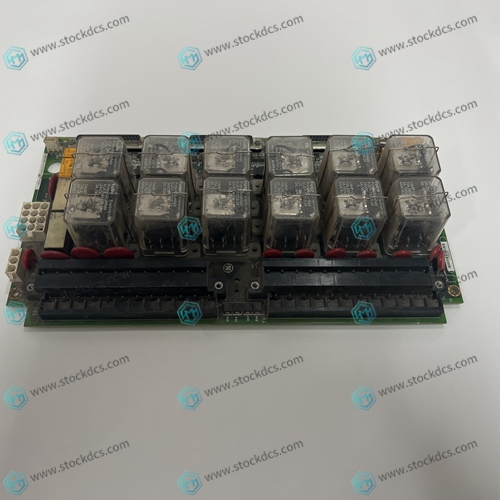

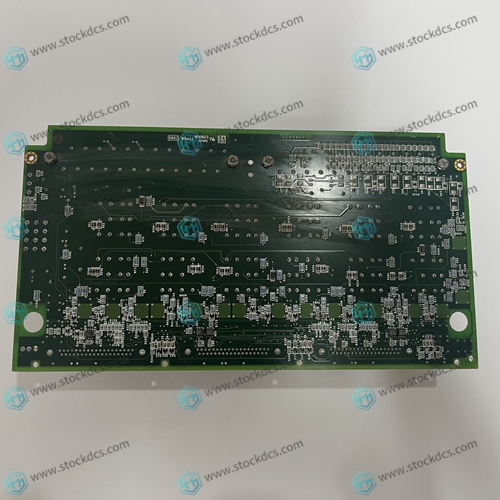

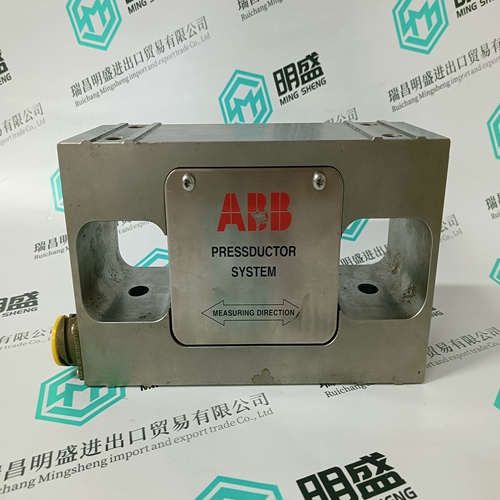

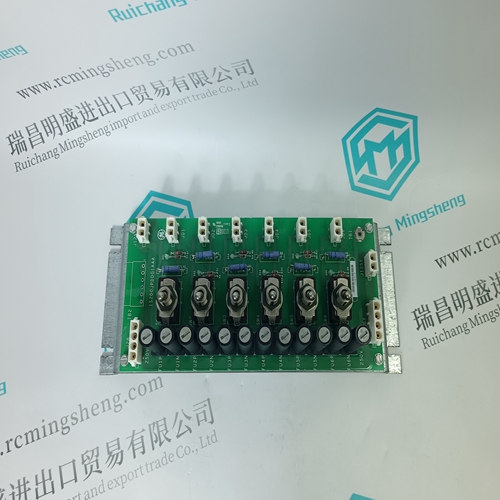

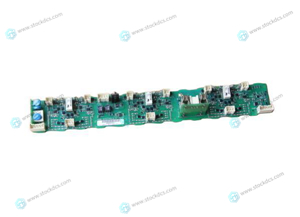

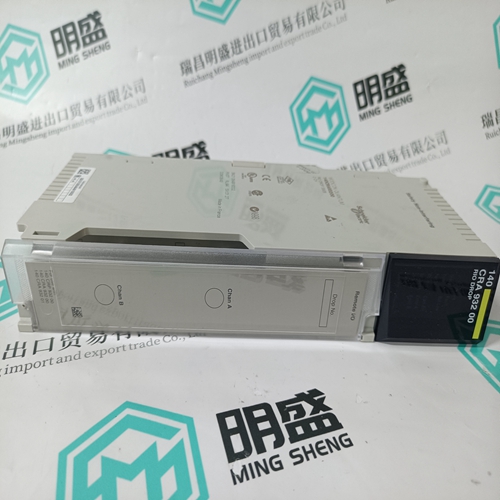

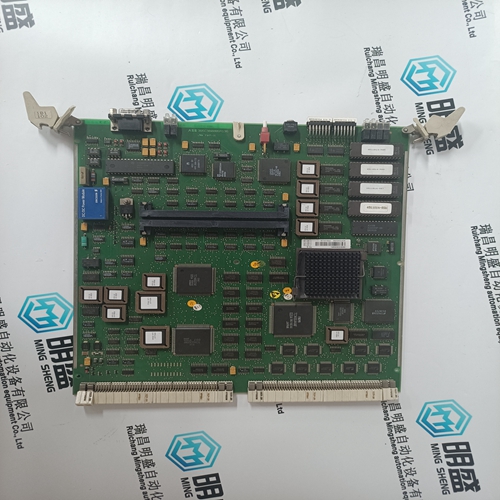

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |