Home > Product > Robot control system > REF545KB133AAAA feeder protection device

REF545KB133AAAA feeder protection device

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:REF545KB133AAAA

- Get the latest price:Click to consult

REF545KB133AAAA feeder protection device

Product Details Introduction

REF545KB133AAAA feeder protection device manual

1、 Product Overview

REF545KB133AAAA feeder protection device is a protection and measurement device designed specifically for power systems by ABB. Its main function is to monitor the operation status of the feeder line and quickly cut off faults in case of short circuits, grounding faults or other abnormal situations, ensuring the stable operation of the power system.

2、 Main features

Quick response: The device can quickly sense abnormal current and voltage signals in the power system, and compare them with preset fault protection conditions. Once a fault is detected, the fault link is immediately cut off to prevent the fault from spreading to the power grid.

Digital signal processing technology: Based on digital signal processing technology, the REF545KB133AAAA feeder protection device can quickly and accurately detect feeder faults and achieve rapid fault removal.

Improving the reliability of power operation: Through real-time monitoring and rapid protection, this device can significantly improve the reliability of power operation and reduce the impact of faults on the power system.

3、 Technical specifications

Model: REF545KB133AAAA

Protection functions: including overcurrent, grounding, phase discontinuity and overload protection, as well as surge monitoring.

Communication capability: Supports multiple communication protocols, facilitating data exchange with other systems or devices.

Installation environment: Suitable for indoor or outdoor environments, but attention should be paid to avoiding adverse factors such as extreme temperature, humidity, and electromagnetic interference.

4、 Installation and debugging

Installation location: A location that is easy to operate, maintain, and observe should be selected for installation.

Power connection: Connect a suitable power source according to the device requirements to ensure stable power supply.

Signal line connection: Connect the corresponding signal lines according to actual needs, and ensure that the line contacts well and is firmly fixed.

Parameter setting: Set appropriate protection parameters and action thresholds based on the actual situation of the power system.

Debugging and testing: After completing the installation and parameter settings, necessary debugging and testing should be carried out to ensure that the device can work properly and meet the requirements.

5、 Operation and Maintenance

Operation interface: The device provides an intuitive and easy-to-use operation interface, making it convenient for users to perform various operations and select functions.

Data display: The device can display the real-time operation status and data information of the power system, helping users to timely understand the system situation.

Fault handling: When the device detects a fault, it will take corresponding actions and alarm prompts, and users can take corresponding actions according to the prompts.

Maintenance: Regular maintenance and upkeep of equipment, including cleaning, tightening screws, inspecting cables, etc., to ensure long-term stable operation of the equipment.

6、 Precautions

During installation and debugging, please ensure compliance with relevant safety regulations and operating procedures to ensure personal and equipment safety.

Please do not change the parameter settings and hardware configuration of the device without authorization to avoid affecting the normal operation and protection function of the device.

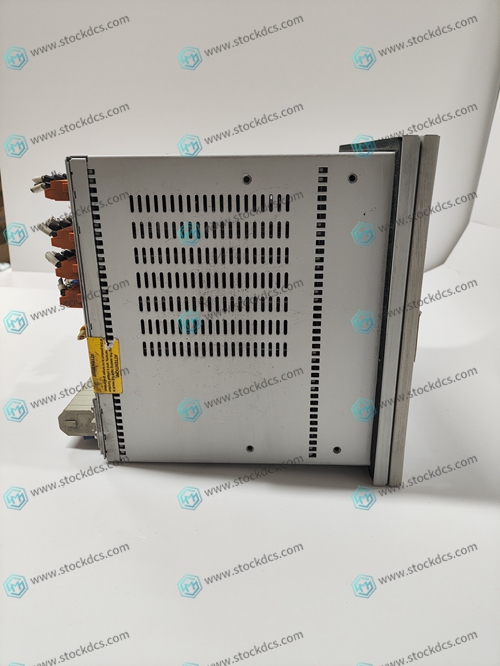

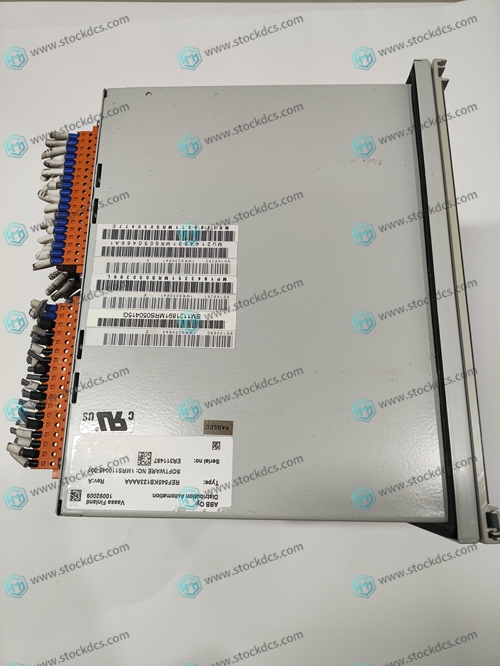

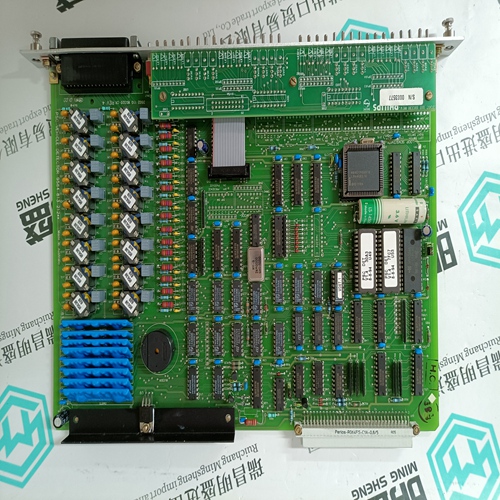

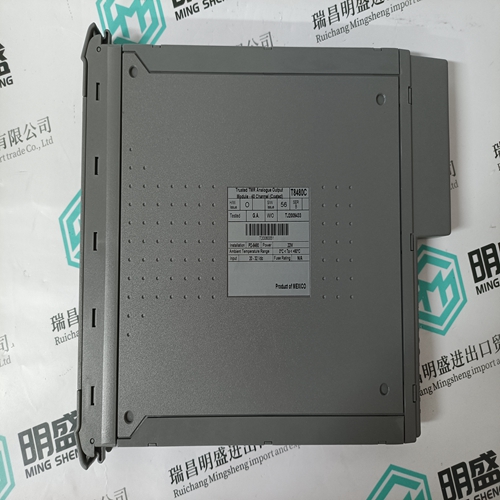

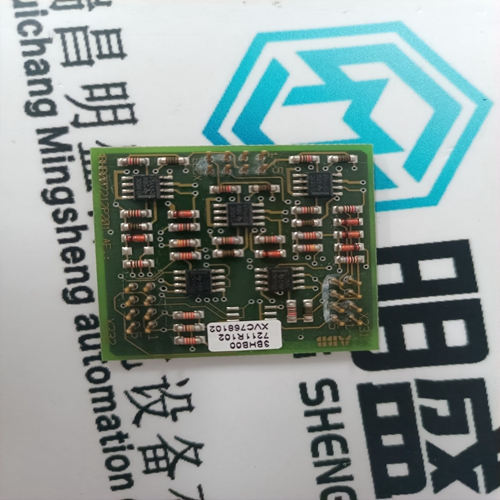

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |