Home > Product > Gas turbine system > IS410STCIS2A IS400STCIS2AFF Process Control I/O Module

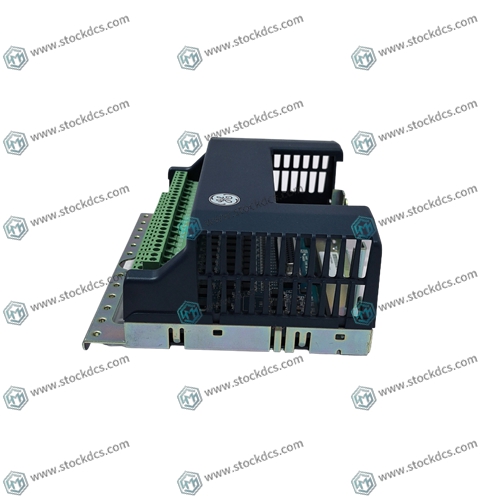

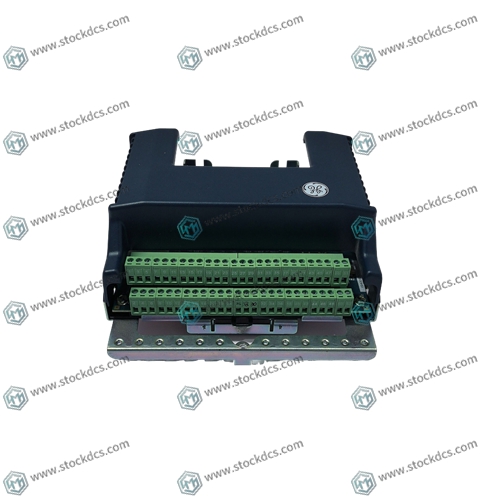

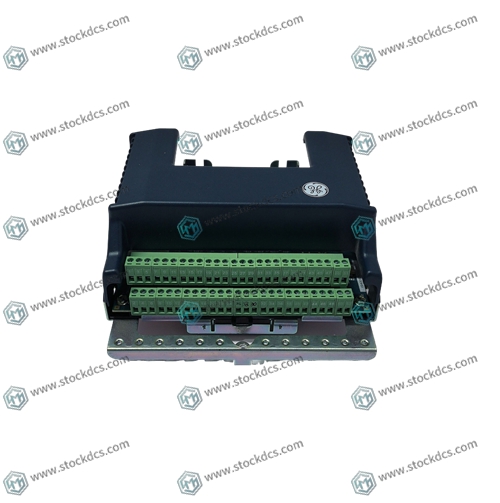

IS410STCIS2A IS400STCIS2AFF Process Control I/O Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

IS410STCIS2A IS400STCIS2AFF Process Control I/O Module

Product Details Introduction

IS410STCIS2A IS400STCIS2AFF Process Control I/O Module Manual

1、 Product Overview

IS410STCIS2A and IS400STCIS2AFF are I/O modules designed specifically for GE's Mark VIe control system, used to connect field devices (such as sensors and actuators) with control systems, achieving high-precision signal processing and data transmission functions. These two modules play a crucial role in industrial processes, ensuring efficient, safe, and reliable operation.

2、 Main features

High precision signal processing:

Capable of processing various types of input and output signals, including analog and digital signals, ensuring high accuracy and reliability in data acquisition and output.

The contact input module provides simplex and the third mock examination Redundancy (TMR) configurations, further enhancing the reliability and stability of signal processing.

Modular design:

Modular design makes installation, maintenance, and expansion more convenient, helping to reduce system downtime and maintenance costs.

Compact and sturdy industrial modules are easy to install and suitable for various industrial environments.

Advanced diagnostic features:

Equipped with advanced self diagnosis function, it can monitor the operation status of modules in real time, quickly detect and report faults, and improve the overall reliability of the system.

The operation status of the PLC controller can be monitored at any time and necessary adjustments can be made through the human-machine interface of the PLC controller or external monitoring equipment.

Compatibility:

Fully compatible with the GE Mark VIe control system, ensuring smooth system integration and overall performance optimization.

Support open connections, such as industrial Ethernet interfaces using MODBUS technology protocol/IP protocol, seamlessly integrated with modern control systems.

Environmental adaptability:

Capable of working in harsh industrial environments, with excellent resistance to vibration, temperature, and dust.

Design to ensure stable operation under various environmental conditions and reduce the risk of downtime caused by environmental factors.

3、 Technical specifications (partial)

Interface: Supports input and output interfaces for multiple signal types.

Performance: With excellent IO throughput and scanning time, it is suitable for high-precision applications such as closed-loop control.

Communication: The industrial Ethernet interface supports MODBUS TCP/IP protocol, enabling efficient data exchange and communication.

4、 Application field

Power plant: used for boiler control, turbine control, and power distribution systems to ensure the efficiency and safety of the power generation process.

Oil and natural gas: Monitor key parameters during oil and gas extraction and refining processes to ensure production continuity and safety.

Chemical and petrochemical: used for reactor monitoring, fluid control, and safety interlock systems to ensure efficient and safe production processes.

Manufacturing: Used in automated production lines for equipment control and process optimization, improving production efficiency and product quality.

5、 Operation and maintenance recommendations

Regular inspection and testing: Regular functional testing and inspection of modules to ensure their accuracy and reliability.

Environmental condition monitoring: Ensure that the working environment of the module meets its specification requirements, avoiding adverse factors such as high temperature, humidity, and electromagnetic interference.

Firmware and software updates: Update the firmware and software of modules in a timely manner to obtain the latest features and security patches.

Maintenance Records: Maintain detailed maintenance records, documenting all testing, calibration, and repair activities to help track the operational status and history of modules.

Spare parts management: Maintain an appropriate inventory of spare parts so that they can be quickly replaced in case of malfunctions and reduce downtime.

6、 Precautions

During installation, use, and maintenance, please follow the instructions and safety operation guidelines in the product manual.

If you have any questions or issues, please contact GE's technical support team or professional maintenance personnel.

Product image

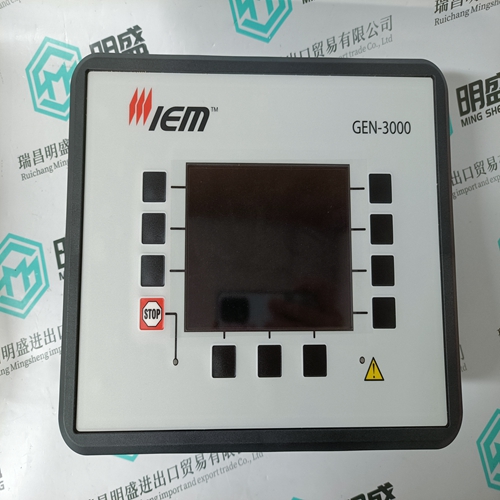

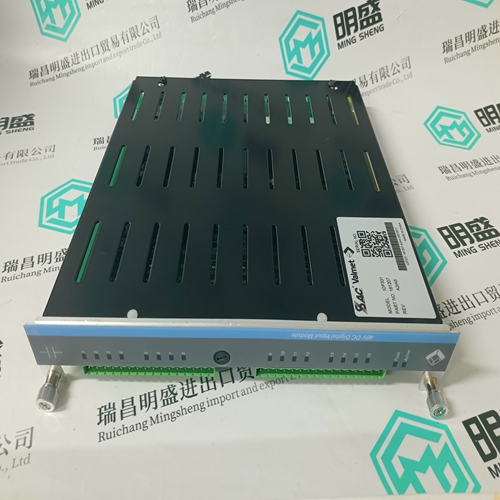

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |