Home > Product > Robot control system > IS400JPDHG1ABB IS410JPDHG1A Feedback Sensor

IS400JPDHG1ABB IS410JPDHG1A Feedback Sensor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

IS400JPDHG1ABB IS410JPDHG1A Feedback Sensor

Product Details Introduction

IS400JPDHG1ABB IS410JPDHG1A Feedback Sensor Manual

1、 Product Overview

IS400JPDHG1ABB and IS410JPDHG1A are shaft speed feedback sensors produced by General Electric (GE). These two sensors are mainly used to measure and provide feedback on the speed information of the shaft in mechanical equipment or systems, supporting motion control systems in the industrial field.

2、 Main features

Signal processing: Equipped with a precision signal conditioning circuit, it can amplify and filter the original sensor signal, improve the signal-to-noise ratio of the signal, and ensure measurement accuracy.

Adaptability: Designed to match the corresponding sensor housing and installation accessories, to adapt to different industrial application environments and equipment.

Compatibility: Compatible with GE's automation control systems and other third-party control systems, providing standard electrical interfaces and communication protocols.

Reliability: Adopting high-quality components and strict manufacturing processes to ensure long-term stable operation in industrial sites, resistant to vibration, impact, temperature and humidity changes, etc.

Diagnostic function: It may integrate self diagnostic function, which can monitor its own working status and report faults or abnormal situations to the control system.

3、 Application scenarios

Machine tools and processing equipment: used to monitor the speed of the spindle or worktable, achieving precise machining control.

Motion control system: used in various motion control systems, such as robots, automated production lines, etc., to monitor the speed of moving components.

Wind power and power generation equipment: used in wind turbines, generators and other equipment to monitor the speed of rotating components and ensure their normal operation.

Conveyor system: monitors the speed of the conveyor belt or drum to achieve accurate conveying and control of materials.

Elevators and lifting equipment: Monitor the speed of the lifting mechanism to ensure its safe and stable operation.

Bearings and transmission system: Monitor the speed of the shaft to ensure the normal operation of the transmission system.

4、 Technical specifications

Measurement range: Suitable for measuring different axis speed ranges.

Output signal: Output 4-20mA signal within the RPM range of the shaft.

Interface options: Multiple interface options may be provided to adapt to different types of control systems and devices.

Housing: Installed in a sturdy XP housing, providing durability and protection.

5、 Installation and Maintenance

Correct installation: During installation, it is necessary to ensure that the circuit board is properly connected to the mechanical structure of the sensor, avoid physical damage, and follow the correct electrical connection specifications.

Environmental factors: When using, environmental factors such as temperature, humidity, and dust should be considered to ensure that the environmental conditions are within the working range of the circuit board.

Power requirements: Confirm the power supply voltage and current requirements to avoid damage to the circuit board caused by overvoltage or undervoltage.

Maintenance: Regularly check the connection and working status of the circuit board, clean dust in a timely manner, and ensure good heat dissipation.

Replacement and Upgrade: If replacement or upgrade is required, it is recommended to search for original or certified alternatives to avoid compatibility or performance degradation issues.

6、 Precautions

During installation and use, please follow the instructions in the product manual to ensure correct and safe operation.

Regularly check the working status of sensors to ensure their accuracy and reliability.

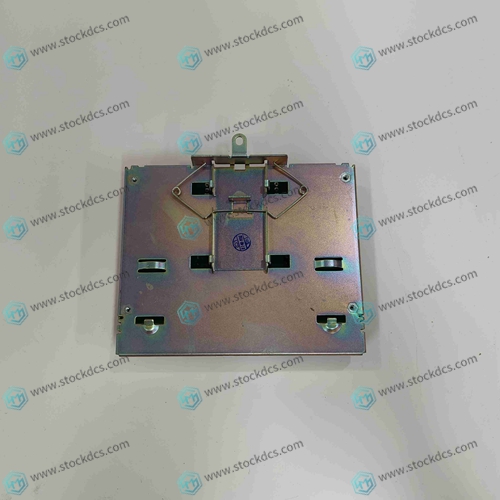

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |