Home > Product > Servo control system > REF615C-E HCFFAEAGABC2BAA11E fieldbus coupler

REF615C-E HCFFAEAGABC2BAA11E fieldbus coupler

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

REF615C-E HCFFAEAGABC2BAA11E fieldbus coupler

Product Details Introduction

REF615C-E HCFFAEAGABC2BAA11E Fieldbus Coupler Manual

1、 Product Overview

REF615C-E HCFFAEAGABC2BAA11E is a dedicated fieldbus coupler that combines networking with the powerful ControlLogix PLC in a user-friendly software package. This coupler is designed for the protection, control, measurement, and supervision of public substations and industrial power systems, and is particularly suitable for radial, circular, and mesh distribution networks with or without distributed generation.

2、 Main features

Comprehensive protection function: Provides comprehensive protection functions, including but not limited to overcurrent protection, short circuit protection, ground fault protection, undervoltage and overvoltage protection, etc., to ensure the stable and safe operation of the power system.

Fieldbus communication: Supports multiple fieldbus protocols such as IEC 61850, Modbus, etc., facilitating seamless communication and data exchange with SCADA systems, substation automation systems (SAS), and other intelligent devices.

Configuration and flexibility: Users can set parameters and configure logic through software to adapt to different power grid structures and operational requirements, improving the adaptability and flexibility of the system.

Diagnosis and event recording: With powerful fault diagnosis and event recording functions, it can record protection actions, system events, and operation history, which is helpful for fault analysis and system maintenance.

Relay protection and control: Integrated with advanced relay protection logic, it can not only quickly respond to faults, but also execute control commands, such as opening and closing operations, to achieve fault isolation and system recovery.

Easy installation and maintenance: compact design, easy to install and maintain, reducing on-site installation workload and maintenance costs.

3、 Technical specifications

(As specific technical specifications may vary depending on different batches or customization requirements, the following is only a general description)

Communication protocol: Supports various fieldbus protocols such as IEC 61850 and Modbus.

Protection functions: including multiple protection functions such as overcurrent, short circuit, ground fault, undervoltage, overvoltage, etc.

Work environment: Suitable for working under various environmental conditions, with a wide working temperature range and IP67 protection level.

4、 Instructions for use

Preparation before installation: Ensure that the installation environment meets electrical safety standards, check that the equipment model matches the system requirements, and prepare necessary installation tools and materials.

Physical installation: According to the installation guidelines provided by the manufacturer, fix the equipment on the designated switchgear or rack, and correctly connect the power and communication lines.

Configuration and debugging: Use specialized configuration software (such as ABB's Relief Configuration Studio) to set device parameters, including protection settings, communication parameters, etc., and conduct functional testing.

System integration: Integrate devices into existing automation systems, configure networks, and ensure smooth communication with upper computer monitoring systems, other protective devices, and other equipment.

On site testing: Before the system is put into operation, conduct on-site testing, including protection function testing, communication function testing, etc., to ensure that all protection logic and control commands work as expected.

Daily maintenance and monitoring: Regularly check the operation status of the equipment, monitor alarm information, update software or firmware as needed, and ensure long-term stable operation of the equipment.

5、 Precautions

Please ensure to follow the installation guidelines provided by the manufacturer for installation and configuration.

When using equipment, please comply with relevant electrical safety regulations and standards.

ther equipment to monitor the speed of rotating components and ensure their normal operation.

Conveyor system: monitors the speed of the conveyor belt or drum to achieve accurate conveying and control of materials.

Elevators and lifting equipment: Monitor the speed of the lifting mechanism to ensure its safe and stable operation.

Bearings and transmission system: Monitor the speed of the shaft to ensure the normal operation of the transmission system.

4、 Technical specifications

Measurement range: Suitable for measuring different axis speed ranges.

Output signal: Output 4-20mA signal within the RPM range of the shaft.

Interface options: Multiple interface options may be provided to adapt to different types of control systems and devices.

Housing: Installed in a sturdy XP housing, providing durability and protection.

5、 Installation and Maintenance

Correct installation: During installation, it is necessary to ensure that the circuit board is properly connected to the mechanical structure of the sensor, avoid physical damage, and follow the correct electrical connection specifications.

Environmental factors: When using, environmental factors such as temperature, humidity, and dust should be considered to ensure that the environmental conditions are within the working range of the circuit board.

Power requirements: Confirm the power supply voltage and current requirements to avoid damage to the circuit board caused by overvoltage or undervoltage.

Maintenance: Regularly check the connection and working status of the circuit board, clean dust in a timely manner, and ensure good heat dissipation.

Replacement and Upgrade: If replacement or upgrade is required, it is recommended to search for original or certified alternatives to avoid compatibility or performance degradation issues.

6、 Precautions

During installation and use, please follow the instructions in the product manual to ensure correct and safe operation.

Regularly check the working status of sensors to ensure their accuracy and reliability.

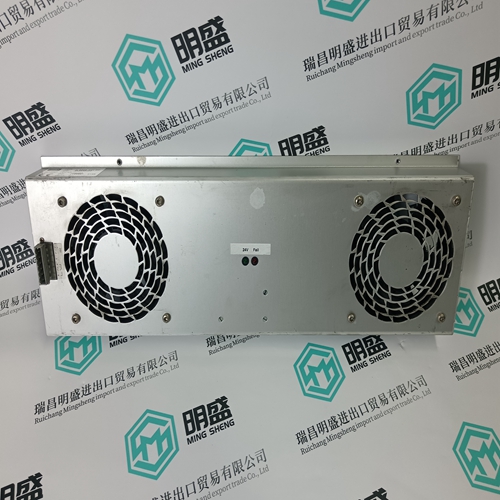

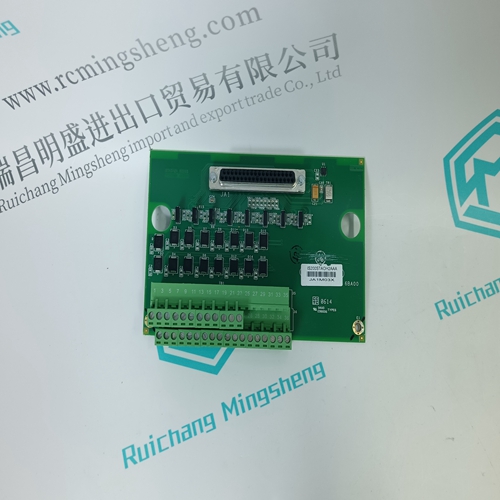

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |