Home > Product > Robot control system > MOOG D136-001-007 motion controller

MOOG D136-001-007 motion controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:D136-001-007

- Get the latest price:Click to consult

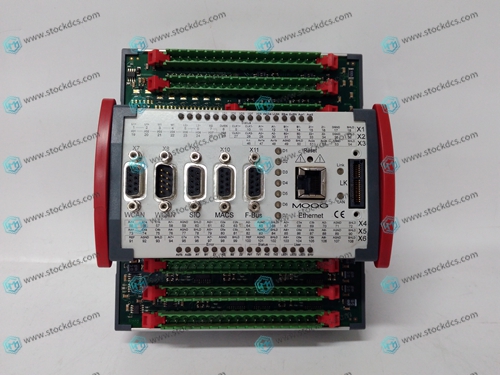

MOOG D136-001-007 motion controller

Product Details Introduction

MOOG D136-001-007 Motion Controller Manual

1、 Product Overview

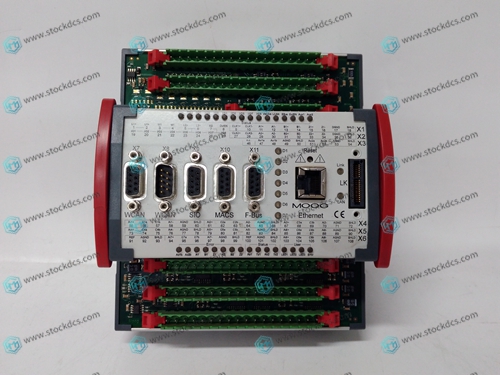

MOOG D136-001-007 motion controller is a high-performance servo controller with PLC function, equipped with high-resolution analog input/output and position sensor interface. This controller is specifically designed to achieve fast and accurate closed-loop control of two hydraulic servo actuators.

2、 Technical specifications

Model and brand:

Model: D136-001-007

Brand: MOOG

Processor and memory:

Processor: PowerPC processor, 32-bit, RISC architecture, with floating-point units

Memory: 4 MB flash EEPROM, data maintenance typically takes 10 years

Installation and dimensions:

Installation method: DIN top cap rail installation

Dimensions: W x D x H (mm) 160 x 170 x 85.5 (Attachment dimensions: W=149/154.5)

Environmental adaptability:

Temperature range:+5 ° C to 55 ° C (operating), -25 ° C to+70 ° C (storage)

Relative air humidity: 10% to 95% (non condensing)

Operating height: maximum 2000 meters

Storage/transportation height: maximum 3000 meters

Input/output characteristics:

Simple wiring with terminal blocks

Analog and digital outputs

Overvoltage protection up to ± 36 V

3、 Functional characteristics

Programmability:

The controller supports free programming and is programmed using the IEC 61131 development environment

MACS (Analog Axis Control Software) enables fast and accurate control

Integrated PLC function:

Integrate PLC functions to achieve communication and coordination with the host

Applicable drives:

Suitable for electric and hydraulic drives

Cycle time:

Has a freely definable controller structure with a cycle time starting from 400 μ s

Error monitoring and protection:

Line fault monitoring for all digital sensor inputs

Analog current output

Scalability:

With M3000 expansion module, additional digital or analog inputs and outputs can be added

Communication interface:

Support Profibus DP slave as an option

4、 Installation and Configuration

Please refer to the detailed installation guide and configuration steps in the product manual for installation and configuration.

5、 Maintenance and upkeep

Regular inspections:

Check the status of connectors and interfaces

Monitoring operational status and indicator lights

Cleaning:

Regularly clean the surface and interior of the controller to prevent the accumulation of dust and dirt

Fault handling:

If any malfunction or abnormality is found in the controller, please contact technical support personnel immediately for handling

6、 Precautions

Please ensure to use this controller under the correct environmental conditions

When installing, configuring, and maintaining, please follow the instructions and safety regulations in the product manual

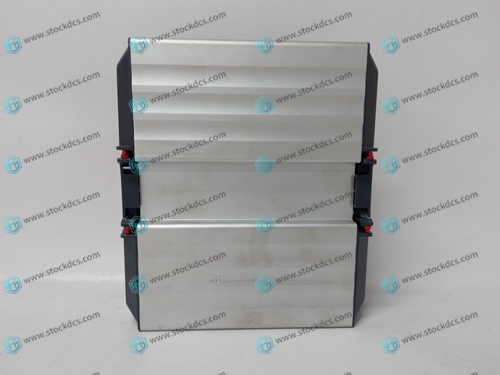

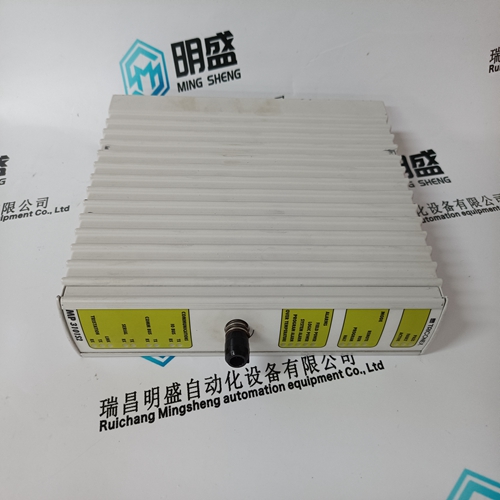

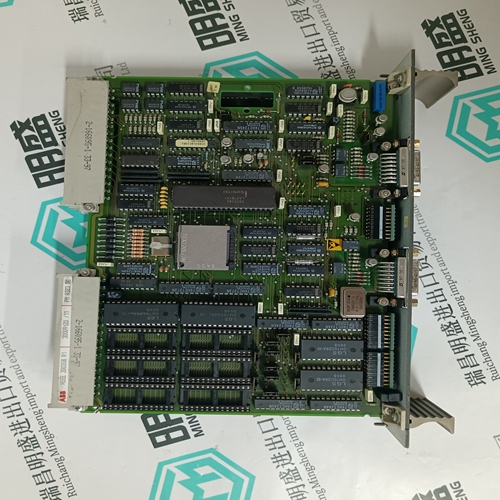

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |