Home > Product > PLC programmable module > Bentley 133819-01 Motion Controller Module

Bentley 133819-01 Motion Controller Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

Bentley 133819-01 Motion Controller Module

Product Details Introduction

Bentley 133819-01 Motion Controller Module Manual

1、 Product Overview

The Bentley 133819-01 motion controller module is a key component in industrial automation and control systems, specifically designed to control motion in mechanical or electromechanical systems, including parameters such as position, velocity, and acceleration. This module is commonly used to control the motion and position in motion control systems, such as robots, CNC machine tools, automatic assembly lines, etc.

2、 Main features

Motion control: Specially designed to control motion in mechanical or electromechanical systems, including parameters such as position, velocity, and acceleration.

Multi axis support: It is usually possible to control multiple axes simultaneously, allowing for complex multi axis coordinated movements.

High precision: With high-precision position control and motion planning functions, suitable for applications with high precision requirements.

Programming: Typically, it is necessary to program a motion control module to define motion trajectories, speed configurations, and other control parameters.

Communication interface: The module usually has multiple communication interfaces for data communication and integration with the upper control system, PLC, human-machine interface (HMI), or other control devices.

Real time monitoring: allows real-time monitoring of the status, operation, and alarm information of the motion axis.

3、 Application field

Industrial robots: used to control the movement and trajectory of industrial robots to achieve various automated tasks, such as assembly, welding, transportation, etc.

CNC machine tool: In CNC (Computer Numerical Control) machine tools, it is used to control the precise position and motion of cutting tools for workpiece processing.

Automated assembly line: used to control various movements on the automatic assembly line, ensuring efficient assembly of products.

Material handling: In logistics and warehousing systems, it is used to control the movement of equipment such as conveyor belts and robotic arms to achieve efficient material handling.

Packaging and Printing: Used in packaging and printing machines to control the accurate position and speed of printing heads or packaging equipment.

4、 Hardware interfaces and functions

Frame reset button: Clearing locked alarms and Timed OK channels has failed, and it has the same function as the "Frame reset" contact on the input/output module.

Address switch: used to set the frame address, with a total of 63 optional addresses.

Configure Keylock: Set the 3500 rack to "RUN" or "Program" mode. The RUN mode allows the framework to operate normally and lock any configuration changes; The Program mode allows the framework to run normally and allows for remote or local configuration of the framework.

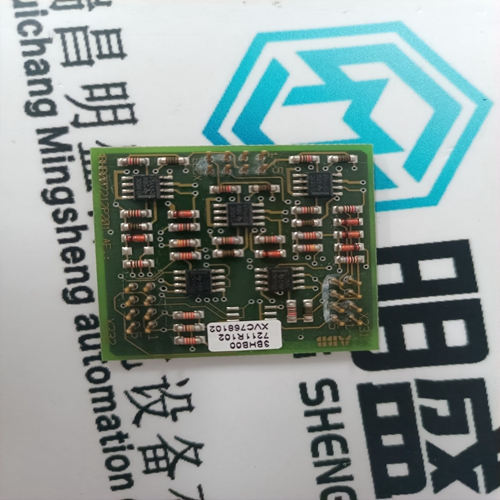

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |