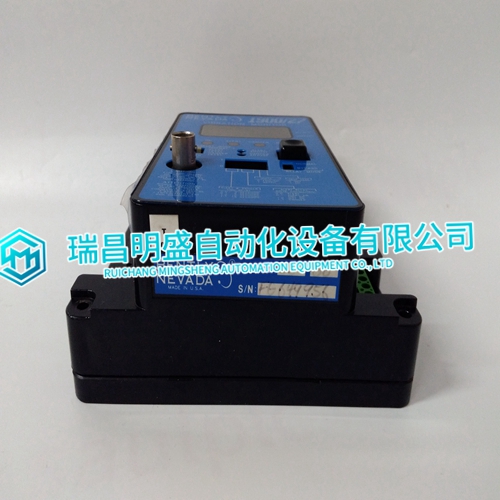

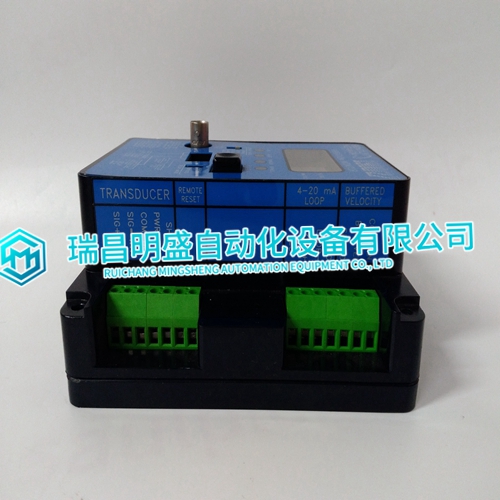

Home > Product > PLC programmable module > BENTLY 1900/27 Monitor module

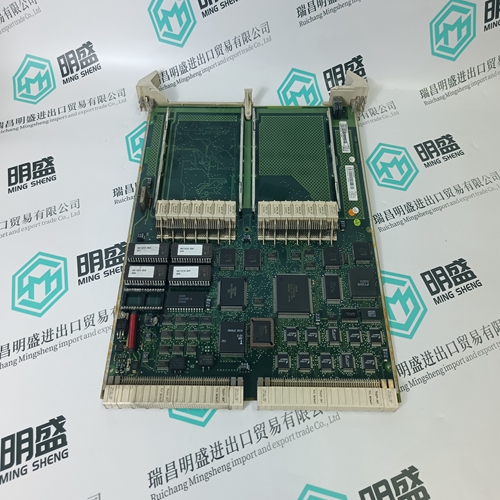

BENTLY 1900/27 Monitor module

- Product ID: 1900/27

- Brand: BENTLY

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:BENTLY1900/27Monitor module

- Get the latest price:Click to consult

BENTLY 1900/27 Monitor module

The control module generates a MISSING SLAVE MODULE error if the I/O expander bus is not connected between it and the digital output module. Verify the bus connection on the MMU backplane. If the I/O module is faulty, replace it with a new one. Refer to the REPAIR/REPLACEMENT PROCEDURES in Section 7 for procedures to replace a DSO module. MODULE PIN CONNECTIONS The digital output module has three connection points for external signals and power (P1, P2 and P3). Tables 5-2, 5-3 and 5-4 show the pin connections.The reliability of any stand-alone product or control system is affected by the maintenance of the equipment. Elsag Bailey recommends that all equipment users practice a preventive maintenance program that will keep the equipment operating at an optimum level.

This section presents procedures

that the customer should be able to perform on site. These preventive maintenance procedures should be used as a guideline to assist in establishing good preventive maintenance practices. Personnel performing preventive maintenance should meet the following qualifications. • Maintenance personnel should be qualified electrical technicians or engineers that know the proper use of test equipment. • Maintenance personnel should be familiar with the module mounting unit, have experience working with process control systems, and know what precautions to take when working on live AC and/or DC systems.

PREVENTIVE MAINTENANCE SCHEDULE

Table 6-1 is the preventive maintenance schedule for the IMDSO14 digital output module. The table lists the preventive maintenance tasks in groups according to their specified maintenance interval. Instructions for tasks that require further explanation are covered under PREVENTIVE MAINTENANCE PROCEDURES. NOTE: The preventive maintenance schedule is for general purposes only. Your application may require special attention. EQUIPMENT AND TOOLS REQUIRED Tools and equipment required for maintenance procedures are: • Antistatic vacuum. • Screwdriver (medium length). • Isopryl alcohol (99.5 percent electronic grade). • Distilled water. • Compressed air. • Foam tipped swabs. • Lint free cloths. • Eberhard Faber (400A) pink pearl eraser.

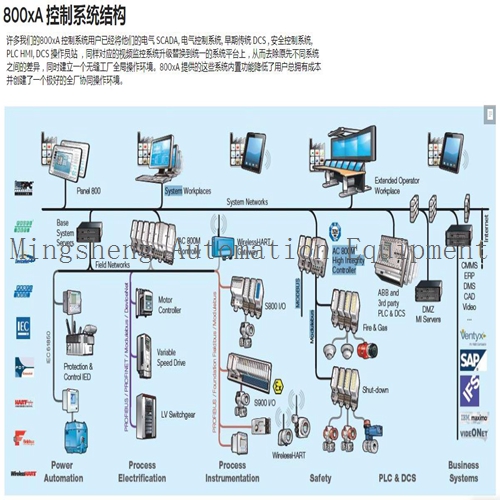

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.