Home > Product > Gas turbine system > DDK NFT-801RM3-S tightening machine

DDK NFT-801RM3-S tightening machine

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

DDK NFT-801RM3-S tightening machine

Product Details Introduction

DDK NFT-801RM3-S Tightening Machine Manual

1、 Product Overview

The DDK NFT-801RM3-S tightening machine is a high-performance tightening equipment that adopts advanced control technology and efficient driving system, providing reliable and accurate tightening solutions for industrial automation. This device is suitable for tightening various fasteners, such as bolts, nuts, etc., and is widely used in fields such as automobiles, machinery, electronics, etc.

2、 Main features

High speed damper: The equipment is equipped with a high-speed damper, which will not cause overshoot even when the speed exceeds 1000 rpm, ensuring the stability and accuracy of the tightening process.

Multi unit advanced communication function: The controller integrates multi unit advanced (PC) communication function, supporting data exchange and communication with other devices or systems, facilitating integrated control and management.

High speed data processing: By utilizing designated high-speed communication between controllers, the processing speed of high-quality data is three times faster than old models, just as fast as Ethernet, meeting the needs of efficient production.

Data storage function: Even without a PC connection, a large amount of data, including high-quality data, can be stored on the CF storage card for convenient data analysis and traceability.

3、 Technical specifications

Model: NFT-801RM3-S

Input voltage: 10 to 55 Vdc

Rated continuous current: 60A

Feedback modes: incremental encoder, EnDat 2.2, and BISS C mode

Operation modes: torque, speed, and position operation modes

Safety function: STO (safety torque shutdown) affects the architecture

4、 Application field

The DDK NFT-801RM3-S tightening machine is suitable for various industrial applications that require high-precision tightening, such as automotive manufacturing, mechanical manufacturing, electronic equipment assembly, etc. It can meet the tightening requirements of different fasteners, improve production efficiency and product quality.

5、 Installation and Maintenance

Installation: Please follow the installation instructions in the product manual to ensure that the device is properly connected and configured. Pay attention to the installation position and fixing method of the equipment to ensure stability and reliability.

Maintenance: Regularly check the operation status of the equipment, including the working condition of components such as power supply, controller, and sensors. If there are any abnormalities, please contact the technical support department in a timely manner for handling. Meanwhile, keep the equipment clean and dry to avoid the impact of dust and moisture on the equipment.

6、 Operating instructions

Preparation work: Check whether the power supply, controller, sensors and other components of the equipment are intact and undamaged to ensure that the equipment is in normal working condition.

Set tightening parameters: Set corresponding torque values, angle values, and other parameters according to tightening requirements to ensure accuracy and qualification rate of tightening.

Start the device: Follow the operating instructions to start the device, and adjust the operating parameters and mode of the device according to actual needs.

Tightening operation: Align the tightening head with the fastener to be tightened, and start the equipment for tightening operation. Pay attention to the operation and tightening effect of the equipment to ensure the quality of tightening.

End operation: After tightening, turn off the equipment switch and wait for the equipment to stop running. Clean up debris and residue around the equipment, keeping it clean and dry.

7、 Precautions

When operating equipment, please follow the safety regulations and operating procedures in the product manual to ensure the safety of personnel and equipment.

Unauthorized modification or disassembly of equipment is prohibited to avoid affecting its performance and safety.

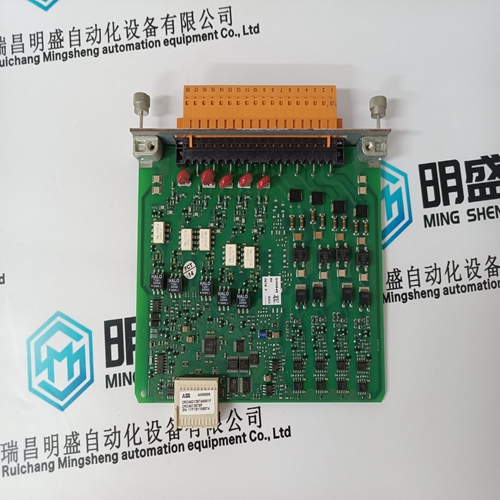

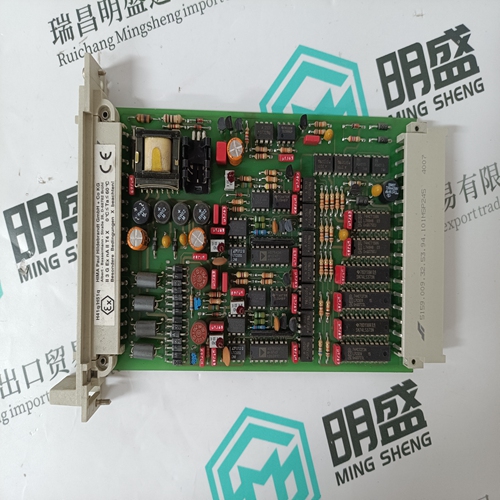

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |