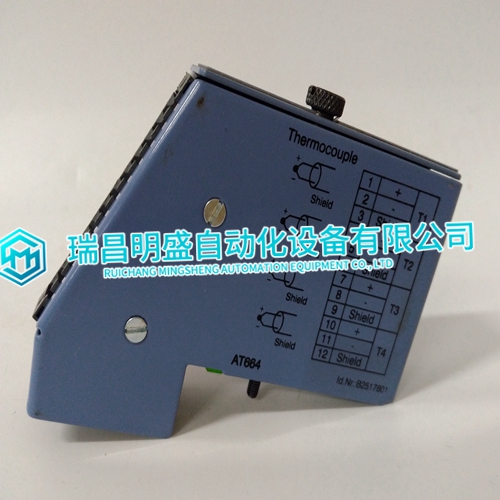

Home > Product > Servo control system > B&R 7AT664.70 Enter the drive

B&R 7AT664.70 Enter the drive

- Product ID: 7AT664.70

- Brand: B&R

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:B&R7AT664.70Enter the drive

- Get the latest price:Click to consult

B&R 7AT664.70 Enter the drive

There are exposed AC and DC connections inside the cabinet. These exposed electrical connections present a shock hazard that can cause injury or death. If input or output circuits are a shock hazard after disconnecting system power at the power entry panel, then the door of the cabinet containing these externally powered circuits must be marked with a warning stating that multiple power sources exist.Check all signal wiring, power and ground connections within the cabinet to verify their integrity. When checking connections, always turn a screw, nut or other fastening device in the direction to tighten only. If the connection is loose, it will be tightened. If the connection is tight, the tightening action will verify that it is secure. There must not be any motion done to loosen the connection. 1. Verify that all power connections within the cabinet are secure. 2. Verify that all wiring connections to the termination unit, or termination module are secure.

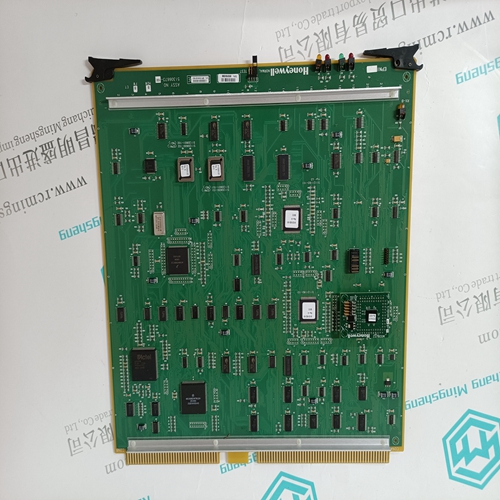

EDGE CONNECTOR CLEANING

Use a solvent mixture of 80% isopropyl alcohol (99.5% electronic grade) and 20% distilled water. 2. Soak a lint free cloth with the solvent mixture. 3. Work the cloth back and forth parallel to the edge connector contacts. 4. Repeat with a clean cloth that is soaked with the solvent mixture. 5. Dry the edge connector contact area by wiping with a clean lint free cloth. To clean tarnished or deeply stained edge connector contacts: 1. Use an Eberhard Faber (400A) pink pearl eraser or equivalent to remove tarnish or stains. Fiberglass or nylon burnishing brushes may also be used. 2. Minimize electrostatic discharge by using the 80/20 isopropyl alcohol/water solution during burnishing. 3. Do not use excessive force while burnishing. Use only enough force to shine the contact surface. Inspect the edge connector after cleaning to assure no loss of contact surface. 4. Wipe clean with a lint free cloth.

This section explains the replacement procedures for the IMDSO14 Digital Output (DSO) module. There are no special tools required to replace a DSO module.Push and turn the two captive retaining screws on the module faceplate one half turn to the latched position. It is latched when the slots on the screws are vertical and the open ends face the center of the module. 6. Return to normal operation.

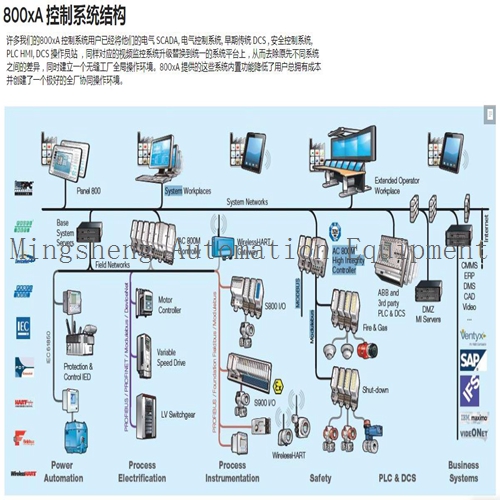

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.