Home > Product > Robot control system > KUKA KSD1-16 E93DA552I4B531 00-122-285 servo driver

KUKA KSD1-16 E93DA552I4B531 00-122-285 servo driver

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

KUKA KSD1-16 E93DA552I4B531 00-122-285 servo driver

Product Details Introduction

KUKA KSD1-16 E93DA552I4B531 is a servo driver commonly used to control and drive servo motors in KUKA industrial robot systems. The following is basic information about this servo driver:

Basic parameters

Model: KSD1-16 E93DA552I4B531

Brand: KUKA

Type: Servo driver

Application: Used to drive and control servo motors in industrial robot systems.

main features

Drive capability: Provides high-performance drive capability for precise control and dynamic response.

Control mode: Supports digital control mode and can communicate in real-time with the robot control system.

Power requirements: Connect to an industrial standard power supply, with specific voltage and power depending on the specific model and configuration.

Programmability: May support customized control logic and motion configurations.

Technical characteristics

Communication interface: It may support various industrial communication protocols, such as CANopen, Ethernet, etc., for data exchange and remote monitoring with the main control system.

Safety functions: may integrate safety functions such as overload protection, error diagnosis, etc. to ensure the safety of equipment and operators.

Durability: Designed for industrial environments, it has good resistance to vibration and corrosion.

Application scenarios

Industrial robots: widely used in various types of industrial robots on automated production lines, such as welding, assembly, and handling.

Motion control: used for precise motion control and path planning, achieving complex operations and tasks.

Production efficiency: Improve production efficiency and product quality, reduce labor costs and production cycles.

Installation and Maintenance

Installation: Install in the appropriate position according to the equipment installation guide and the structure of the robot system.

Debugging: Perform parameter configuration and debugging to ensure compatibility and stability between the driver and the robot system.

Maintenance: Regularly check the operating status and communication connections of the drive, and promptly handle faults and abnormalities.

Usage suggestions

Selection: Select the appropriate servo drive model based on specific drive requirements, motor specifications, and robot system requirements.

Configuration: Use the configuration tools or software provided by the manufacturer to correctly configure and calibrate the parameters of the servo drive.

Training: Operators and maintenance personnel should receive relevant training to understand the usage and maintenance skills of servo drives.

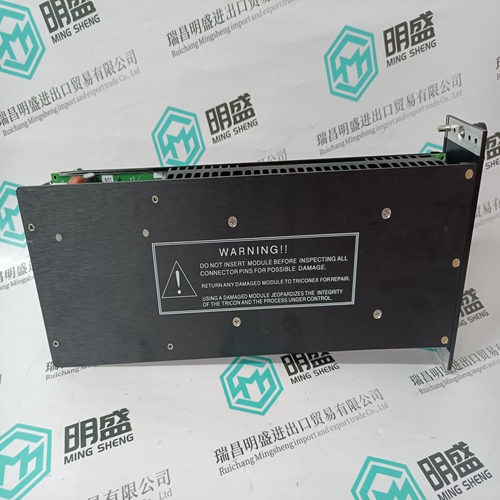

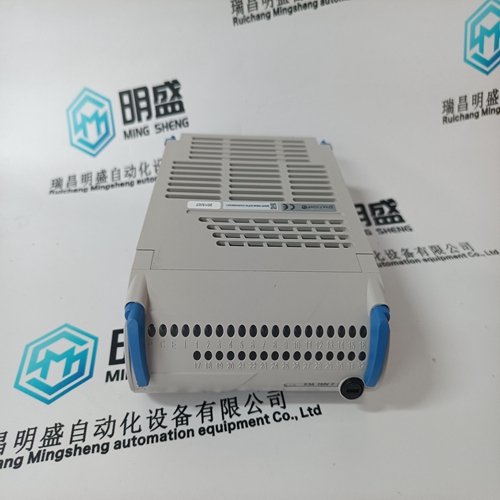

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |