Home > Product > Robot control system > KUKA KSD1-32 E93DA113I4B531 servo driver

KUKA KSD1-32 E93DA113I4B531 servo driver

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

KUKA KSD1-32 E93DA113I4B531 servo driver

Product Details Introduction

KUKA KSD1-32 E93DA113I4B531 is a servo driver suitable for controlling and driving servo motors in KUKA industrial robot systems. The following is the basic information about this servo driver:

Basic parameters

Model: KSD1-32 E93DA113I4B531

Brand: KUKA

Type: Servo driver

Application: Mainly used to drive and control servo motors in industrial robot systems.

main features

Driving capability: Provides high-performance driving capability that enables precise motion control and dynamic response.

Control method: Supports digital control, real-time communication with robot control system, and realizes complex tasks and path planning.

Power requirements: Connect to an industrial standard power supply, and the specific voltage and power depend on the specific model and configuration.

Programmability: It may support customized control logic and motion configurations to meet different application requirements.

Technical characteristics

Communication interface: It may support various industrial communication protocols, such as CANopen, Ethernet, etc., for data exchange and remote monitoring with the main control system.

Safety functions: Multiple safety functions may be integrated, such as overload protection, error diagnosis, etc., to ensure the safety of equipment and operators.

Durability: Designed for industrial environments, it has good resistance to vibration and corrosion, ensuring long-term stable operation.

Application scenarios

Industrial robots: widely used in various types of industrial robots on automated production lines, such as welding, assembly, and handling.

Motion control: used to achieve complex motion control and precise position adjustment, improving production efficiency and product quality.

Production optimization: By precise motion control and adjustment, optimize the production process, reduce energy consumption and production costs.

Installation and Maintenance

Installation: According to the equipment installation guide and the structure of the robot system, install in the appropriate position and ensure good electrical connections.

Debugging: Perform parameter configuration and debugging to ensure compatibility and stability between the driver and the robot system.

Maintenance: Regularly check the operating status and communication connections of the drive, promptly handle faults and abnormalities, and ensure the long-term stable operation of the system.

Usage suggestions

Selection: Select the appropriate servo driver model based on specific drive requirements, motor specifications, and robot system requirements.

Configuration: Use the configuration tools or software provided by the manufacturer to correctly configure and calibrate the parameters of the servo drive.

Training: Operators and maintenance personnel should receive relevant training to understand the usage and maintenance skills of servo drives, and improve the efficiency and safety of system operation.

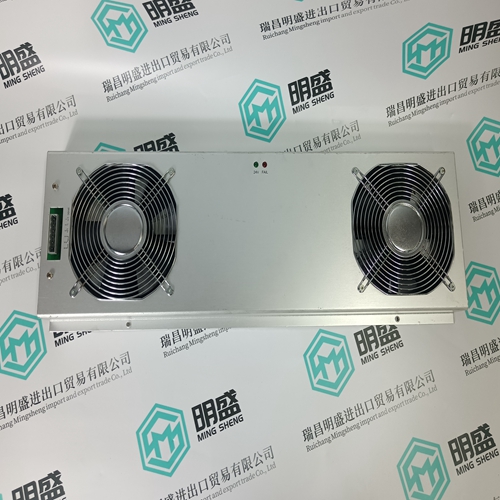

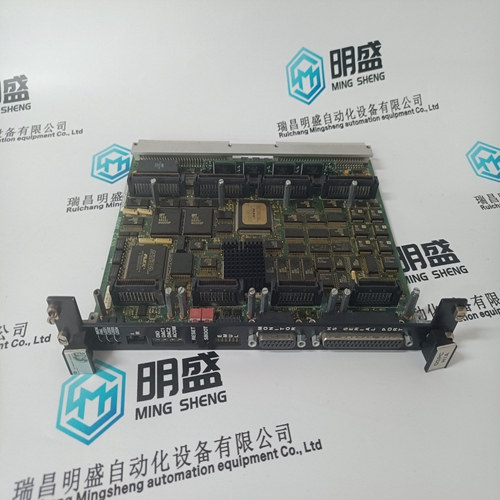

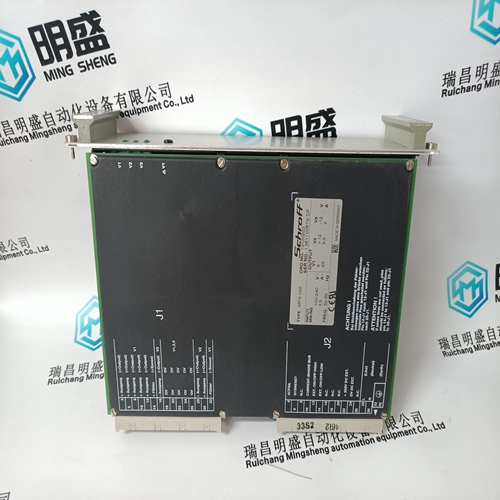

Product image

Related products:

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

其他网站链接

BENTLY 350022M 138607-01系统模块卡件

| PMB33F-10200-02 | 07ZE62R302 | P22NRXB-LDN-NS-00 |

| PMB31B-10201-00 | 07ZE63R302 | P22NRXA-LNF-NS-00 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB31B-10216-03 | 07ZE88 | P22NRXA-LDN-HD-00 |

| PMB31D-20116-00 | 07ZG60R1 | N33HCHJ-LNK-NS-00 |

| PMB33C-20101-03 | 07ZW80 | N33HCHK-LNS-NS-02 |

| PMB33E-10114-01 | 07BE61R1 | N32HSHK-LNK-NS-02 |

| PMB33E-00216-02 | 07PT40 | N32HRLK-LNK-NS-00 |

| PMB33E-00216-00 | ECZ | N31HRFL-LNK-NS-00 |