Home > Product > DCS control system > EPRO MMS6823/9100-00001-05 sensor

EPRO MMS6823/9100-00001-05 sensor

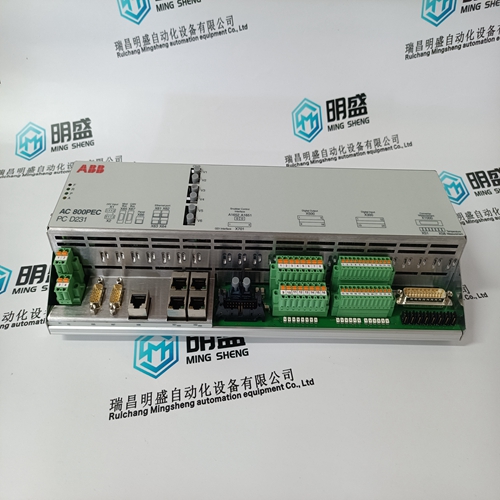

- Product ID: MMS6823/9100-00001-05

- Brand: EPRO

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:EPROMMS6823/9100-00001-05sensor

- Get the latest price:Click to consult

EPRO MMS6823/9100-00001-05 sensor

My DSP Group My DSP Group is a hardware unit for organizing up to 50 Sending DSP subunits, with the same Major DSP ID, sent from this station (also referred to as My Station). The receiving DSP subunits should not be added under My DSP Group. DSP Send and DSP Receive The two hardware units - DSP Send and DSP Receive - represent the DSPs that the CI869 sends and receives respectively. The Minor DSP ID together with the Major DSP ID gives the DSP ID. The Major DSP ID, which is determined by the position number of the hardware unit above the DSP, can be from 1 to 80. The position number of the DSP [1...50] gives the Minor DSP ID. The ID can be modified by changing the position of the DSP (moving it up or down in the HW tree). The DSPs are categorized as either DSP Send (the source communication unit) or as DSP Receive (the sink communication unit), and have a defined cycle time.

The cycle time is used at the source to define the sending period, and at the sink to define the time-out. For DSP Receive, the time-out occurs if no slave frame is received within four cycles, or within eight cycles (if Double DSP Timeout is configured for CI869 unit).If the DSPs in the CI869 hardware tree give a bus load greater than 80%, an error is displayed during download of the hardware configuration to the controller, and the download is aborted. If the DSPs in the CI869 hardware tree give a bus load greater than 70%, a warning is displayed during download of the hardware configuration to the controller. The load calculation in Control Builder is based only on the DSPs from individual CI869 unit. The complete DSP configuration is compiled by the Bus Master, and it is no guarantee that the configuration downloaded to the AC 800M can be used on the bus.

32 Bytes Data Consistency

The 32 byte consistency can be achieved by setting the parameter 32 Bytes Data Consistency, which is available for DSP Send and DSP Receive. If the 32 Bytes Data Consistency is enabled (true), the Consistency channel in the DSP Send or DSP Receive hardware editor must be connected to a variable which is written after each reading/writing of the DSP. The Consistency channel is an output channel. It must be used as follows: • Connect the Consistency channel to a boolean variable. • For a DSP Receive, a value must be assigned to the connected variable (the value does not matter, that is, it can be set true or false) in the same program that reads the DAT-channels of the DSP. The assignment must be done at each execution cycle.

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on