Home > Product > DCS control system > Yaskawa CACR-SR1B-E control board

Yaskawa CACR-SR1B-E control board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Yaskawa CACR-SR1B-E control board

Product Details Introduction

The Yaskawa CACR-SR1B-E control board is part of the Yaskawa servo drive and is widely used in industrial automation systems. The following are some key features and application areas of this control board:

main features

High precision control:

Provide precise speed, position, and torque control to ensure stability and accuracy in high-performance applications.

Multi functional interface:

Support multiple communication interfaces, such as RS-232, RS-485, Ethernet, etc., for easy integration with other control systems.

High reliability:

Designed to be sturdy and durable, capable of long-term stable operation in harsh industrial environments.

Intelligent diagnostic function:

Built in self diagnostic function, real-time monitoring of device status, convenient for maintenance and troubleshooting.

Flexible control mode:

Support multiple modes such as position control, speed control, and torque control to meet different application requirements.

technical parameter

Input voltage: usually 200-230V AC or 380-480V AC, specific models may vary.

Output power: Please refer to the product manual for the specific power range.

Communication interfaces: RS-232, RS-485, Ethernet, etc.

Control modes: position control, speed control, torque control.

Working environment: Suitable for a working temperature range of 0-50 ° C.

application area

Industrial automation:

Manufacturing automation production line: Control equipment such as robotic arms and conveyor belts on the production line to achieve efficient and accurate production operations.

Packaging machinery: used to control various actions of packaging machines, such as packaging, cutting, labeling, etc., to ensure the packaging process is fast and accurate.

robotics:

Industrial robots: Control the movement of robot joints, provide precise positioning and path planning, suitable for welding, assembly, transportation and other operations.

Collaborative robots: provide safe and flexible motion control in scenarios where humans work together.

numerical control machine:

Lathe, milling machine, grinding machine: Control the motion axis of the machine tool to achieve high-precision machining operations, improve machining efficiency and quality.

Laser cutting machine: provides precise motion control to achieve laser cutting of complex patterns.

Semiconductor manufacturing:

Wafer processing equipment: provides high-precision motion control in the cutting, polishing, testing and other processes of wafers.

Packaging testing equipment: used for mechanical motion control in packaging and testing processes to ensure product quality.

Printing and Textile:

Printing machine: Control the various moving parts of the printing machine to achieve high-speed and high-quality printing.

Textile machine: Control the weaving process of the textile machine to ensure the uniformity and quality of the fabric.

Medical equipment:

Imaging equipment: Provides precise motion control in X-ray machines, CT machines, and other devices to ensure imaging quality.

Surgical robots: provide precise motion control, assist in surgical procedures, and improve the accuracy and safety of surgery.

Logistics and warehousing:

Automated warehousing system: controls equipment such as conveyors and elevators in the automated warehousing system to achieve efficient storage and retrieval of goods.

AGV (Automatic Guided Vehicle): Used to control the movement of AGV and achieve automated material handling in the warehouse.

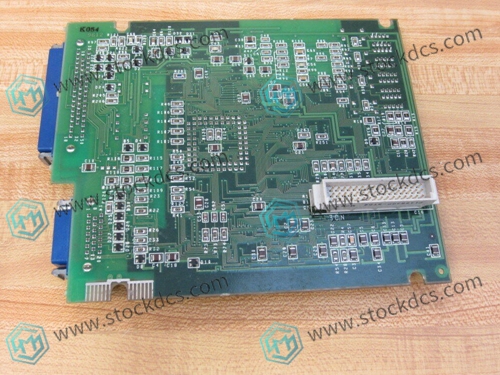

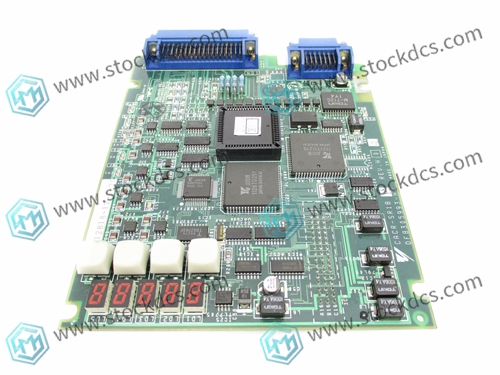

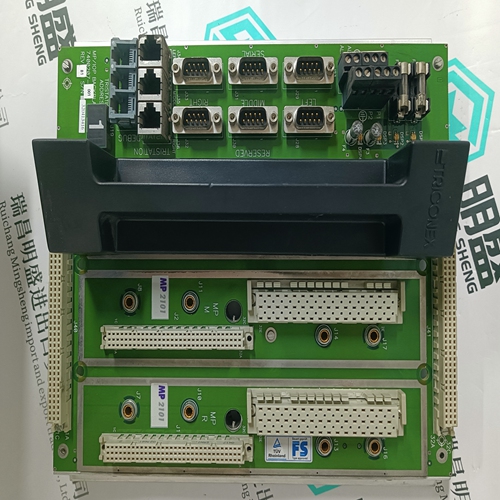

Product image

Related products:

UFC760BE143 inverter high-voltage board

REF615E-E HBFEAEAGABCCANC11E Measurement

KOLLMORGEN S70602-NANANA servo/driver

其他网站链接

ABB TVB-1202-1ANET 1381-647980-12 电路板模块

| PMB33C-20216-03 | NKTU02 | M21NSXC-LSS-SS-02 |

| PMB31D-20200-00 | NKTU110 | M21NRXB-LNN-NS-00 |

| PMB33C-20200-00 | NKTU111 | M22NRXA-LNF-NS-00 |

| PMB33F-10216-00 | NKTU112 | M21NRXB-LDN-NS-00 |

| PMB33F-10100-01 | NKTU113 | M22NRXA-JNN-NS-00 |

| PMB31D-00214-00 | NKTU115 | M22NRXA-LDN-M1-00 |

| PMB31B-00100-00 | NKTU116 | M21NSXC-LNN-NS-02 |

| PMB31B-00200-03 | NKTU117 | M22NRXD-LNN-NS-00 |

| PMB31D-10214-00 | NMFC04 | M22NRXA-LDN-NS-00 |