Home > Product > DCS control system > Yaskawa CACR-SR15BF1BMB driver module

Yaskawa CACR-SR15BF1BMB driver module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Yaskawa CACR-SR15BF1BMB driver module

Product Details Introduction

Yaskawa CACR-SR15BF1BMB is a servo driver module suitable for high-performance industrial automation systems. This driver module can accurately control the speed and position of servo motors and is widely used in various automation and motion control applications. Here are some detailed information about the driver module:

Main features:

High performance control: Adopting advanced vector control algorithms, it can achieve high-precision speed, position, and torque control.

Multifunctional: Supports multiple control modes, including position control, speed control, and torque control, to meet different application requirements.

Easy to integrate: Compatible with various industrial automation equipment and systems, making it easy to integrate into existing control systems.

Protection function: It has multiple protection functions such as overcurrent, overvoltage, undervoltage, overheating, short circuit, etc., to ensure the safe operation of the equipment.

Communication capability: Supports multiple industrial communication protocols, facilitating remote monitoring and control.

Technical specifications:

Input voltage: three-phase AC 200-230V

Output power: 15kW

Output current: maximum 60A

Control methods: vector control, V/f control

Maximum output frequency: 400Hz

Communication interface: RS-232/RS-485, optional modules such as Profibus, DeviceNet, EtherNet/IP, etc

Application field:

Industrial automation: suitable for CNC machine tools, injection molding machines, textile machinery and other equipment.

Robots: widely used in industrial robots and automated production lines.

Printing and packaging: used for precise motion control in printing machines and packaging equipment.

Material handling: used for speed and position control in conveyor belts, cranes, and other equipment.

Semiconductor manufacturing: used for high-precision positioning control in semiconductor equipment.

Installation and maintenance:

Installation: It is carried out by professional technicians to ensure the correct connection and good grounding of the power supply and servo motor.

Debugging: Use Yaskawa's dedicated debugging software to set parameters and debug, ensuring that the device runs at its optimal state.

Maintenance: Regularly check the operation status of the drive, clean the heat sink, check the connection condition, and prevent loosening and aging.

Common problem solving:

Overcurrent fault: Check if the connection between the motor and driver is correct, and confirm that there is no short circuit or overload situation.

Communication failure: Check the connection of the communication cable, confirm whether the communication parameters are set correctly, and ensure that the communication module is working properly.

Abnormal noise and vibration: Check whether the motor and mechanical load are normal, eliminate mechanical faults, and ensure smooth system operation.

Usage suggestions:

Environmental requirements: Ensure that the installation environment is clean and dry, and avoid excessive dust and moisture that may affect equipment operation.

Temperature control: Ensure that the operating environment temperature of the equipment is within the specified range to prevent overheating.

Regular maintenance: Follow the requirements of the equipment manual for regular maintenance and upkeep to extend the service life of the equipment.

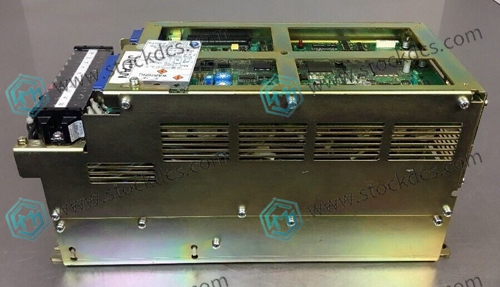

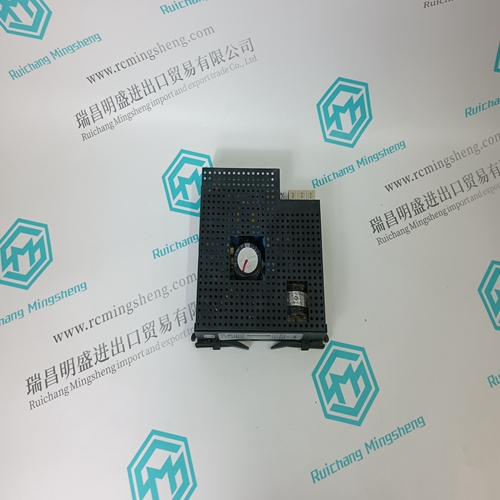

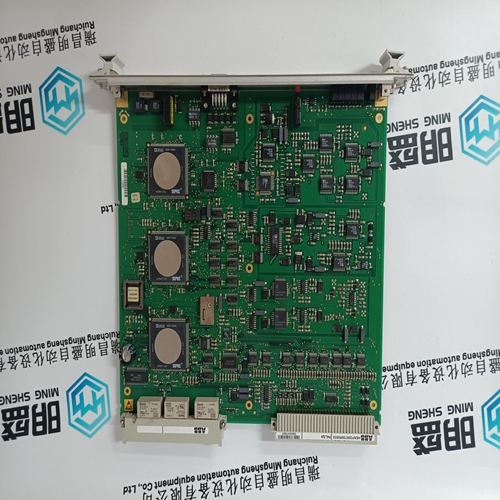

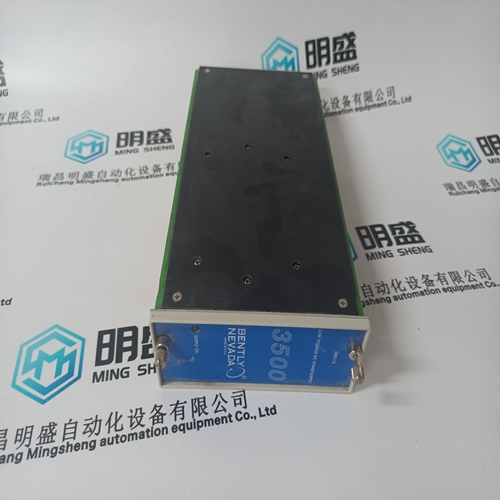

Product image

Related products:

UFC760BE143 inverter high-voltage board

REF615E-E HBFEAEAGABCCANC11E Measurement

KOLLMORGEN S70602-NANANA servo/driver

其他网站链接

| S22GNNA-RNNM-00 | SC402-012-T4 | SC103-001-T3 |

| S32GMNA-RNNM-00 | SC402-010 | SC105010I3 |

| S33GMNA-RNNM-00 | SC403-012-T3 | SC104-036-T3 |

| T Series | SC402-003-T3 | SC755A-040-08 |

| T Series | SC403-001-T2 | SC754B-001-01 |

| T21NRLC-LNN-NS-00 | SC402-001-T2 | SC755A-001-01 |

| T Series | SC403-002-T2 | SC756B-001-02 |

| T22NRLG-LNN-NS-00 | SC402-024-T2 | SC753A-040-08 |