Home > Product > Gas turbine system > Hydran 201Ci-C Single Channel Transformer Control Unit

Hydran 201Ci-C Single Channel Transformer Control Unit

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

Hydran 201Ci-C Single Channel Transformer Control Unit

Product Details Introduction

GE Hydran 201Ci-C is a single channel transformer control unit used for transformers and other oil immersed electrical equipment. It mainly achieves early fault warning by monitoring the dissolved gases in transformer oil. The following is detailed information about the Hydran 201Ci-C single channel transformer control unit:

main features

Gas monitoring: Hydran 201Ci-C focuses on monitoring hydrogen (H ₂) and humidity (moisture content) in transformer oil. Hydrogen is an early indicator of internal faults in transformers, such as overheating and arc discharge.

Early fault detection: By continuously monitoring the hydrogen and humidity content, early warning is provided to help users intervene before the problem evolves into a serious fault.

Single channel design: designed specifically for monitoring a single transformer or device, suitable for key monitoring of a single device.

Communication Interface: Supports multiple communication interfaces, such as 4-20mA and RS485 (Modbus RTU), for remote data transmission and integration into existing monitoring systems.

Alarm function: Equipped with programmable alarm settings, when the monitoring value exceeds the set threshold, the device will issue an alarm to remind users to take measures.

Compact design: The equipment is compact and easy to install on existing transformers and other oil immersed electrical equipment.

technical specifications

Monitoring gases: hydrogen (H ₂), humidity (water content)

Hydrogen measurement range: 0-2000 ppm

Humidity measurement range: 0-100% RH

Precision:

Hydrogen: ± 10% or ± 25 ppm (whichever is higher)

Humidity: ± 3% RH

Response time: Hydrogen<30 minutes (90% gas concentration change)

Communication interface: 4-20mA, RS485 (Modbus RTU)

Working temperature range: -40 ° C to+55 ° C

Protection level: IP65

application area

Power Transformer: Used to monitor the internal gas content and humidity level of power transformers to prevent faults from occurring.

Industrial transformer: applied on large transformers in industrial facilities to ensure the reliable operation of equipment.

Wind farm transformer: used to monitor the health status of wind farm transformers and prevent sudden failures.

Monitoring the status of other oil immersed electrical equipment, such as reactors, transformers, and other critical equipment.

advantage

Early fault warning: By continuously monitoring the hydrogen and humidity content, potential problems can be identified in a timely manner to prevent further deterioration of the fault.

Improve equipment reliability: Enhance equipment reliability and operational safety, and reduce unexpected shutdowns.

Reduce maintenance costs: Identify and address issues in advance, and reduce maintenance and repair costs.

Easy to integrate: Multiple communication interfaces support, making it easy to integrate into existing monitoring systems and achieve centralized management.

Easy installation: The device is compact in design, and easy to install and maintain.

Installation and maintenance

The installation and maintenance process of Hydran 201Ci-C is simple, usually including the following steps:

Choose installation location: Determine the appropriate location for the transformer or equipment oil tank for installation.

Install sensor: Fix the sensor on the oil tank wall to ensure it can come into contact with transformer oil.

Connect power and communication lines: Follow the instructions to connect the power and communication lines to ensure the normal operation of the equipment and data transmission.

Calibration and testing: Perform calibration and functional testing according to the manufacturer's instructions to ensure accurate and reliable operation of the equipment.

conclusion

GE Hydran 201Ci-C is an efficient and reliable single channel transformer control unit suitable for various oil immersed electrical equipment. By continuously monitoring key gas and humidity levels, it helps users identify potential issues in the early stages and take necessary preventive measures to ensure the safe operation of the equipment.

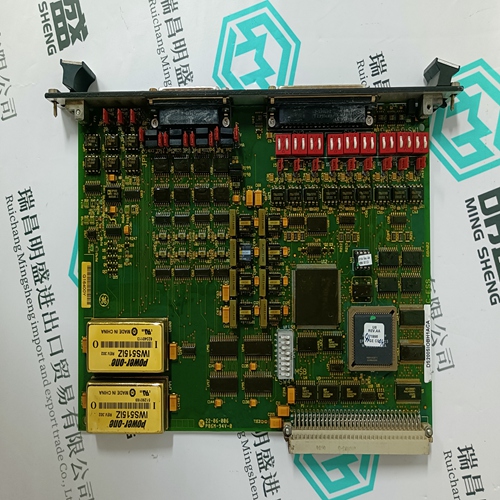

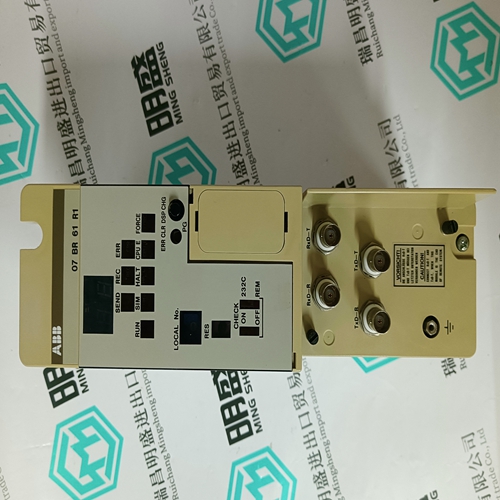

Product image

Related products:

ABB XVC768117 Field Input/Output Module

ABB 3DDE300417 Input/Output Board

ABB XXD129A01 Card Module Controller

其他网站链接

| PMB31B-00214-03 | AMAT 0100-09367 | PFRL101C 2.0KN 3BSE023316R0002 |

| PMB31B-00114-03 | AMAT 0100-18039 | PFRL101D 5.0KN 3BSE002969R0002 |

| PMB33E-00101-02 | AMAT 0100-00112 | PFCL301E 0.2KN 3BSE016580R200 |

| PMB22B-10100-00 | AMAT 0100-09131 | PFCL301E 0.5KN 3BSE016580R500 |

| PMB33E-10114-02 | AMAT 0100-09084 | PFCL301E 1.0KN 3BSE016580R1000 |

| PMB33C-20216-00 | AMAT 0100-00056 | PFTL301E 0.1KN 3BSE019050R100 |

| PMB31B-10200-02 | AMAT 0100-03133 | PFTL301E 0.2KN 3BSE019050R200 |