Home > Product > Robot control system > ASEA YB560103-CE Robot Control Board

ASEA YB560103-CE Robot Control Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

ASEA YB560103-CE Robot Control Board

Product Details Introduction

ASEA YB560103-CE Robot Control Board is a control board specifically designed for industrial robot systems, responsible for control and management tasks within the robot system. This type of control board is typically used to implement robot motion control, task execution, and system integration. The following is detailed information about the ASEA YB560103-CE robot control board, including application areas, main functions, and technical features:

application area

Industrial automation:

In industrial automation systems, it is used to control robots to perform various automation operations, such as assembly, handling, welding, etc., to improve production efficiency and accuracy.

Mechanical manufacturing:

In mechanical manufacturing and CNC machine tools, managing robots to perform complex machining tasks and operations improves the accuracy and consistency of the manufacturing process.

Automobile manufacturing:

In the automotive production line, controlling robots for automated assembly, welding, spraying and other processes improves the flexibility and efficiency of the production line.

Electronic product assembly:

In the assembly process of electronic products, control robots to perform precise operations such as component placement, welding, and inspection to ensure product quality and consistency.

Food and packaging industry:

In food processing and packaging lines, controlling robots for automated processing and packaging operations improves the speed and hygiene standards of the production line.

Pharmaceutical industry:

Used in pharmaceutical manufacturing and packaging to control robots for precise operations, ensuring product quality and production safety.

major function

Robot motion control:

Provide high-precision motion control functions, including position control, speed control, and path planning, to ensure that the robot executes operations according to predetermined trajectories and tasks.

Task Execution:

Support programming and execution of complex tasks, including assembly, handling, welding, spraying, etc., to meet the needs of various industrial applications.

Real time feedback:

Real time monitoring of robot operation status, providing real-time feedback and data to help optimize operations and improve system stability.

Data communication:

Support data communication with other control systems and devices to ensure system coordination and real-time data transmission, compatible with multiple communication protocols.

Fault diagnosis:

Equipped with fault diagnosis function, it helps detect and locate problems in the system, provides repair and maintenance support, and reduces downtime.

User interface:

Provide a user-friendly interface for system configuration, programming, and operation, simplifying user operations and system management.

Technical features

High reliability:

Industrial grade design, suitable for harsh working environments, with high anti-interference ability and durability, capable of long-term stable operation.

high-precision:

Provide high-precision control and operation capabilities, suitable for industrial application scenarios that require high precision.

Flexibility:

Supports multiple programming and configuration options, and can be flexibly configured and adjusted according to different application requirements.

compatibility:

It has good compatibility and can be integrated with various robot systems and control devices to adapt to different industrial environments and application requirements.

Easy to maintain:

The design is simple, easy to install, debug, and maintain, reducing system downtime and maintenance costs.

Real time performance:

Provide low latency control and feedback to ensure real-time performance and response speed of the robot system, suitable for high dynamic operating environments.

summary

ASEA YB560103-CE robot control board is a key industrial robot control component widely used in various automation and robot systems. Its high reliability, precision, and flexibility make it an ideal choice in industrial automation, effectively improving the control capability and operational efficiency of robot systems. Whether in the fields of mechanical manufacturing, automotive production, or electronic assembly, the ASEA YB560103-CE control board can provide stable control and management functions.

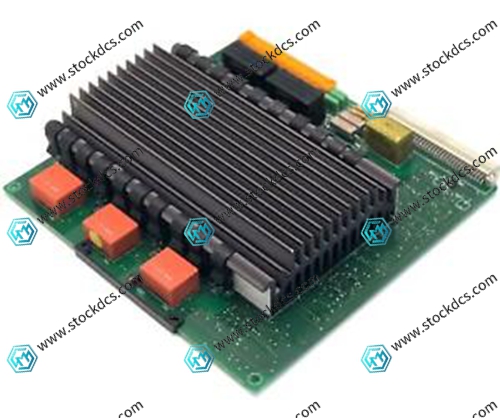

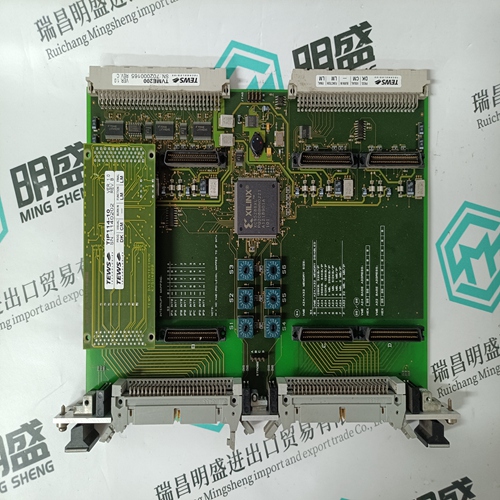

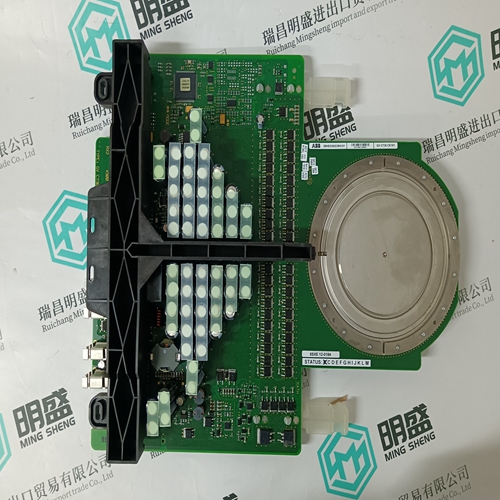

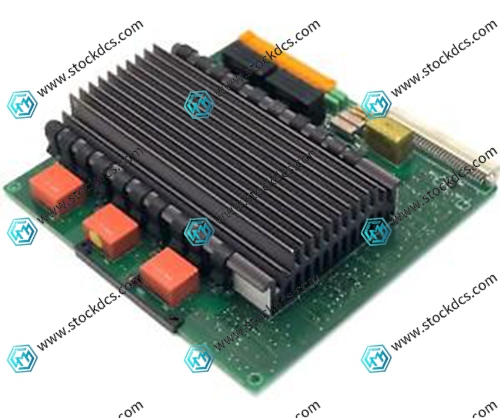

Product image

Related products:

ABB UN1024c-P Remote Terminal Module

ABB UN0942b-P Programmable Controller

ABB UN0821B-P redundant output module

其他网站链接

| PMB33E-20114-02 | 70 SK 34b-E | PWM3624-5437-7-1 |

| PMB33C-20200-03 | 70 SK 36b-E | R43HEAA-R2-NS-VS-00 |

| PMB33F-00114-02 | 70 SK 37b-E | R33GENT-TS-LA-NV-02 |

| PMB33C-00201-01 | 70 SL 01a | R23GENA-R1-NS-NV-00 |

| PMB31D-00216-01 | 70 VV 01a | R32GENC-TS-NS-VS-00 |

| PMB31D-00214-03 | 70 WA 01a-E | R32HSNG-TS-NS-NV-02 |

| PMB33F-20101-03 | 70 WB 01a | R45GSNA-R2-NS-NV-03 |

| PMB33F-20200-00 | 70AA01a-E | R45HCNA-TS-NF-NV-00 |