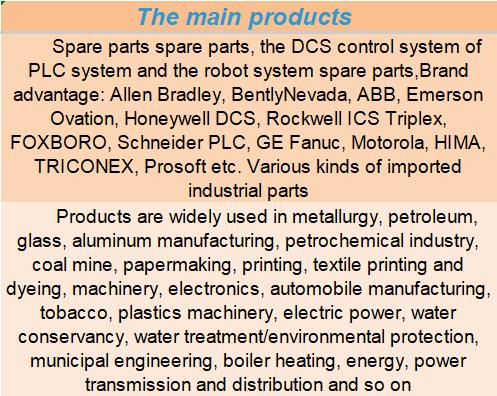

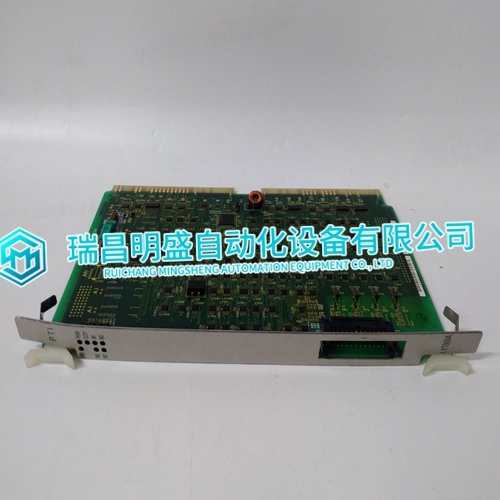

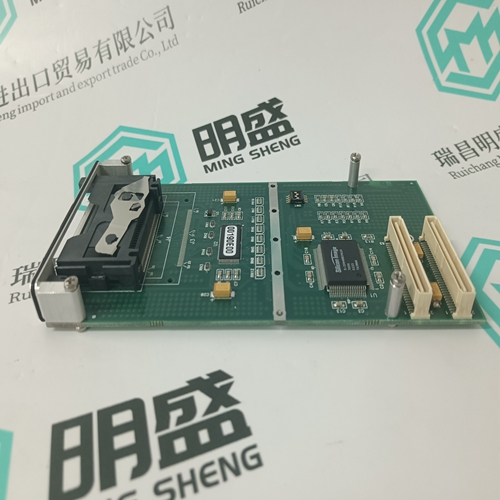

Home > Product > DCS control system > HITACHI LYT000A Switch module

HITACHI LYT000A Switch module

- Product ID: LYT000A

- Brand: HITACHI

- Place of origin: JAPAN

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HITACHILYT000ASwitch module

- Get the latest price:Click to consult

HITACHI LYT000A Switch module

EQUIPMENT AND TOOLS REQUIRED Tools and equipment required for maintenance procedures include: • Antistatic vacuum. • Clean, lint free cloth. • Compressed air. • Eberhard Faber (400A) pink pearl eraser or equivalent. • Fiberglass or nylon burnishing brush. • Foam tipped swab. • Bladed screwdriver suitable for terminal blocks. • Isopropyl alcohol (99.5 percent electronic grade). • Natural bristle brush. PREVENTIVE MAINTENANCE PROCEDURES This section covers tasks from Table 6-1 that require specific instruction or further explanation: • Checking signal, power and ground connections. • Cleaning printed circuit boards.

Checking Connections

Check all signal wiring, power and ground connections within the cabinet to verify their integrity. When checking connections, always turn a screw, nut or other fastening device in the direction to tighten only. If the connection is loose, it will be tightened. If the connection is tight, the tightening action will verify that it is secure. There must not be any motion done to loosen the connection. NOTE: Power to the cabinet must be off while performing this preventive maintenance task. Verify that all cable connections are secure.

WARNING

There are exposed AC and DC connections inside the cabinet. These exposed electrical connections present a shock hazard that can cause injury or death. If input or output circuits are a shock hazard after disconnecting system power at the power entry panel, then the door of the cabinet containing these externally powered circuits must be marked with a warning stating that multiple power sources exist.

Never clean electrical parts of components with live power present. Doing so exposes you to an electrical shock hazard. Wear eye protection whenever working with cleaning solvents. When removing solvents from printed circuit boards using compressed air, injury to the eyes could result from splashing solvent as it is removed from the printed circuit board.