Home > Product > Servo control system > Asea YB161102-BH servo controller board

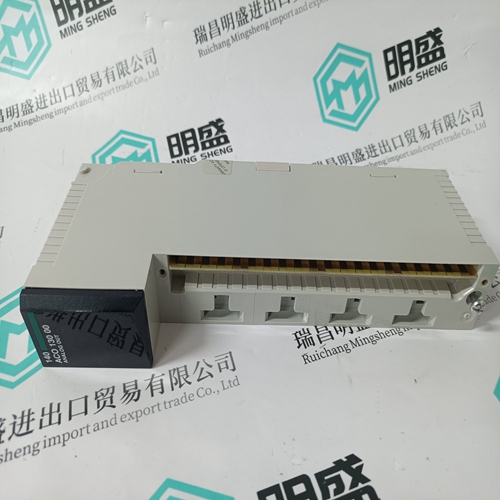

Asea YB161102-BH servo controller board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Asea YB161102-BH servo controller board

Product Details Introduction

The ASEA YB161102-BH servo controller board is a key component used by ASEA (now ABB) in industrial automation and servo systems. This servo controller board is responsible for controlling the precise motion of servo motors, processing data from sensors, and executing complex control algorithms.

main features

Function:

Servo motor control: Manage the motion of servo motors, including position, speed, and torque control.

Feedback processing: Receive and process signals from encoders or other feedback devices to achieve precise motion control.

Data Communication: Provides communication interfaces with other control systems or modules for data exchange and system integration.

Technical specifications:

Processor: Equipped with high-performance processors for real-time processing of control tasks and algorithms.

Storage: With an appropriate amount of memory and storage space, it is used to store control programs, parameters, and data.

Input/output interfaces: including various digital and analog input/output interfaces, supporting the connection of various sensors and actuators.

Communication interface: Supports standard communication protocols such as RS-232, RS-485, Ethernet, etc., facilitating system integration and data exchange.

Performance characteristics:

High precision control: Achieve high-precision position, speed, and torque control of servo motors, suitable for precision motion applications.

Real time response: Supports real-time data processing and fast response, ensuring stable and efficient system operation.

High reliability: Designed to be durable and suitable for harsh industrial environments, ensuring long-term stable operation.

Application areas:

Automated production line: used to control servo motors on automated production lines, achieving precise material handling, assembly, and processing.

Robot system: In industrial robots, it is used to control servo motors to achieve precise robot movements and operations.

Numerical Control Machine Tool: In numerical control machine tools, it is used to control the movement of motors and achieve high-precision machining and manufacturing.

Installation and configuration:

Installation method: It is usually a modular design that is easy to install in control cabinets or racks, fixed with screws or connected with slots.

Configuration method: Set parameters and download programs through dedicated configuration software to ensure module compatibility and system performance.

Maintenance and Support:

Regular maintenance: Regularly check the connection status and operating parameters of the controller board, and perform necessary firmware upgrades and hardware maintenance.

Technical support: ABB provides professional technical support, including installation guidance, debugging support, and troubleshooting services.

Application examples

Automated production line: used in applications such as conveyor systems and assembly robots on production lines to precisely control the movement of servo motors, improve production efficiency and product quality.

Industrial robots: In various robot applications such as welding, handling, and assembly, they are responsible for precise control of servo motors to ensure stable operation of the robots.

Numerical Control Machine Tool: In mechanical processing, high-precision cutting and machining operations are achieved by precisely controlling servo motors.

Product image

Related products:

RADISYS 451558-004 Communication Module

ABB XVC768117 Field Input/Output Module

Other website links

| PMB31B-00114-00 | 07AB67R1 | P21NRLC-LSS-NS-03 |

| PMB33E-00216-01 | 07AB90-S | P21NRXB-JNF-NS-00 |

| PMB33E-10116-03 | 07AS82 | P21NRXB-LDN-PD-00 |

| PMB33C-10114-02 | 07BA60R1 | P21NRXB-LNS-NS-05 |

| PMB31D-20216-01 | 07BE60R1 | P22NSXA-LNN-NS-02 |

| PMB33F-10101-03 | 07BE62R1 | P22NSXA-LSS-SS-03 |

| PMB33C-10101-01 | 07BR60R1 | P21NSXS-LSS-NS-08 |