Home > Product > Servo control system > ASEA YT212002-AD Robot Control Board

ASEA YT212002-AD Robot Control Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

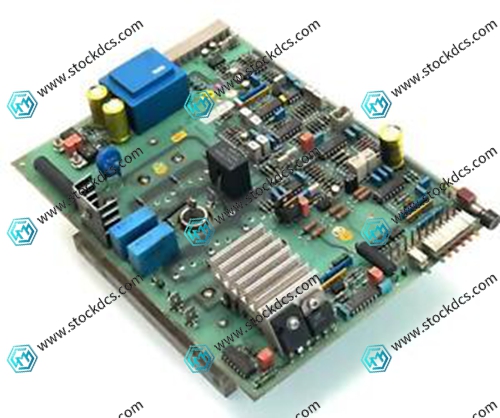

ASEA YT212002-AD Robot Control Board

Product Details Introduction

The ASEA YT212002-AD robot control board is a key component used by ASEA (now ABB) for industrial robot systems. This control board is responsible for handling various control tasks of the robot system, including motion control, data processing, and system integration.

main features

Function:

Motion control: Manage the motion of the robot, including position, velocity, and acceleration control, to ensure precise motion of the robot.

Signal processing: Processing data from sensors and encoders, real-time monitoring of robot status, and adjusting control strategies.

Task scheduling: Execute predetermined control tasks and operating procedures to achieve complex automation tasks.

Technical specifications:

Processor: Equipped with high-performance processors, capable of real-time processing of complex control algorithms and task scheduling.

Storage: Having sufficient memory and storage space for storing control programs, operating parameters, and data logs.

Input/output interfaces: including various digital and analog input/output interfaces, supporting the connection of various sensors and actuators.

Communication interface: Supports multiple standard communication protocols such as RS-232, RS-485, Ethernet, etc., facilitating data exchange with other systems or devices.

Performance characteristics:

High precision control: Achieving high-precision position, velocity, and acceleration control, suitable for precise robot operations.

Real time response: Supports real-time data processing and fast response, ensuring the stability and efficiency of the robot system.

High reliability: Designed to be sturdy and suitable for long-term stable operation in various industrial environments.

Application areas:

Industrial robots: used in various industrial robot systems, such as welding robots, handling robots, assembly robots, etc., to control the precise movement of robots.

Automated production line: Control robots in the automated production line to perform operations such as material handling, assembly, and processing.

Complex process operations: applied in process operations that require highly precise control and flexibility, such as electronic component assembly and high-precision machining.

Installation and configuration:

Installation method: Modular design, usually installed in the robot control cabinet, fixed by screws or connected by slots.

Configuration method: Use specialized configuration software for parameter settings and program downloads to ensure compatibility and performance optimization between the control board and the robot system.

Maintenance and Support:

Regular maintenance: Regularly check the connection status and operating parameters of the control board, and perform necessary firmware upgrades and hardware maintenance.

Technical Support: ABB provides comprehensive technical support, including installation guidance, debugging support, and troubleshooting services, to help users ensure the optimal operation of the system.

Application examples

Welding robot: In the welding process, control the precise motion and welding path of the robot to ensure welding quality and consistency.

Handling robots: In material handling and logistics systems, control robots to handle and sort items, improving efficiency and accuracy.

Assembly robot: On the assembly line, control the robot to assemble and install components, improving production speed and accuracy.

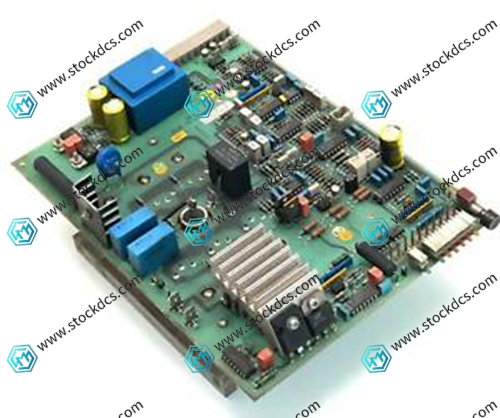

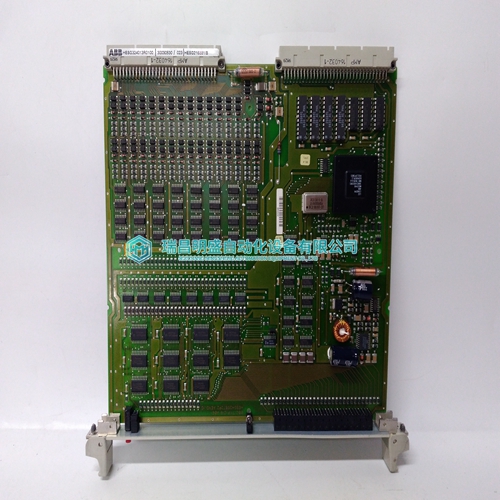

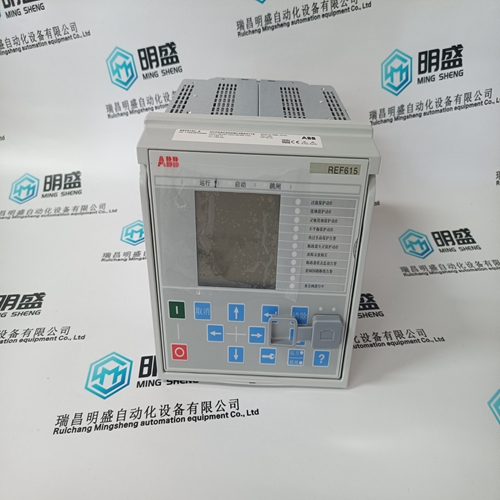

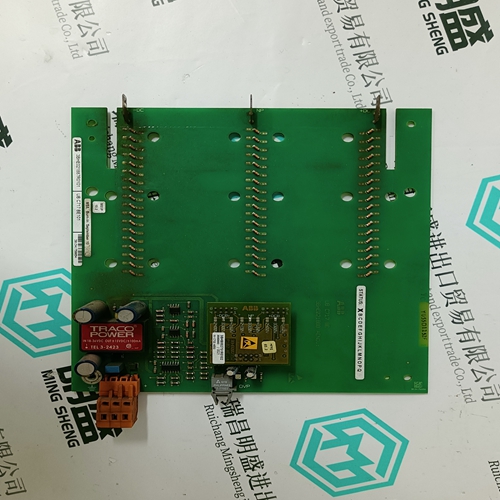

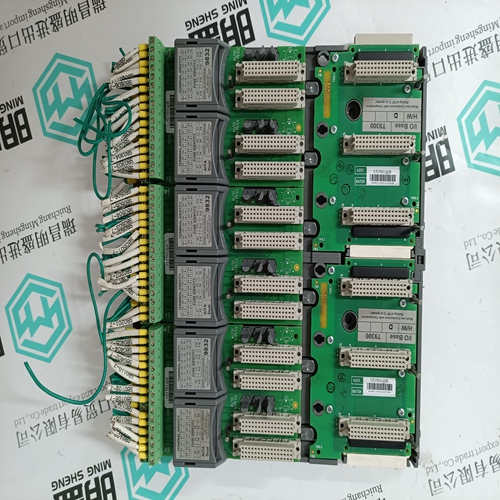

Product image

Related products:

ABB XVC768117 Field Input/Output Module

Other website links

| PMB33F-10201-03 | 07BR61R1 | P21NRXD-LDN-NS-00 |

| PMB32D-00116-03 | 07BT60R1 | P22NSXA-LNF-NS-02 |

| PMB33E-10116-02 | 07BT62R1 | P22NSXC-LSN-NS-03 |

| PMB31D-10201-00 | 07BV60R1 | P22NRXB-LNN-NS-00 |

| PMB33F-00101-00 | 07CS61 | P21NSXC-LSN-NS-02 |

| PMB33F-10116-03 | 07EA200 | P21NSXS-LSS-NS-04 |

| PMB31D-20116-03 | 07EA60R1 | P21NSXS-LSS-M1-02 |

| PMB33F-00116-02 | 07EA61R1 | P21NRXC-LDN-NS-00 |