Home > Product > PLC programmable module > ASEA 3HAA3563-AHA Robot Control Board

ASEA 3HAA3563-AHA Robot Control Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

ASEA 3HAA3563-AHA Robot Control Board

Product Details Introduction

ASEA 3HAA3563-AHA is a robot control board primarily used for control and management tasks in ASEA (now ABB) robot systems. This control board plays a core role in robot control systems, processing various control signals, executing programs, and managing the robot's movements.

Main features of ASEA 3HAA3563-AHA robot control board

High performance processor:

Built in high-performance processor capable of processing complex control instructions and real-time data, ensuring efficient operation of the robot system.

Multi functional interface:

Provide multiple input and output interfaces for connecting sensors, actuators, and other peripheral devices, supporting various functions and expansion requirements of robot systems.

High precision control:

Designed for high-precision control and motion management, ensuring that robots can perform precise operations and path planning.

Real time data processing:

Support real-time data processing and feedback, able to monitor the status of the robot system in real time and make corresponding control adjustments.

compatibility:

Compatible with multiple ASEA (ABB) robot systems, it can seamlessly integrate into existing automation control systems.

Fault diagnosis and alarm:

Provide fault diagnosis and alarm functions, enabling real-time monitoring of system status, timely detection and handling of potential problems, ensuring system stability and reliability.

User friendly interface:

Designed a user-friendly interface for easy configuration and operation, supporting simplified programming and debugging processes.

application area

1. Industrial robots

Motion control: used to control the motion of industrial robots on the production line, perform precise operations and path planning, and improve production efficiency and product quality.

Task Execution: Manage robots to perform various tasks such as welding, spraying, assembly, and handling, ensuring efficient and accurate operations.

2. Manufacturing industry

Automated production line: In an automated production line, controlling the movement and operation of the robot system improves the automation level and production capacity of the production line.

Precision machining: used for precision machining tasks such as cutting, drilling, polishing, etc., to ensure high precision and quality during the machining process.

3. Automotive industry

Automotive assembly: In the automotive assembly line, control robots to perform assembly operations such as body welding, component installation, etc., to improve assembly efficiency and accuracy.

Quality inspection: used for quality inspection of automotive components, controlling robots to perform inspection tasks to ensure product quality.

4. Electronic industry

Electronic product manufacturing: used for the manufacturing and assembly of electronic products, controlling robots for precision operations and testing, and supporting efficient production processes.

Component processing: Control robots to process electronic components, such as picking, placing, welding, etc., to improve the automation level of the production line.

5. Food processing

Automated packaging: In food processing production lines, controlling robots for packaging, sorting, and classification improves production efficiency and packaging quality.

Product handling: Used for product handling tasks, such as transferring food from the production line to the packaging area, to improve automation levels.

6. Manufacturing of medical equipment

Medical device assembly: used in the assembly process of medical equipment, controlling robots to perform precise operations to ensure high-quality medical device production.

Automated testing: Control robots to perform testing and calibration of medical equipment, supporting efficient testing processes.

overview

The ASEA 3HAA3563-AHA robot control board plays a core role in industrial automation and robot systems, supporting precise control and efficient operation of robots through high-performance processing capabilities and multifunctional interfaces. It is widely used in fields such as industrial robots, manufacturing, automotive industry, electronics industry, food processing, and medical equipment manufacturing.

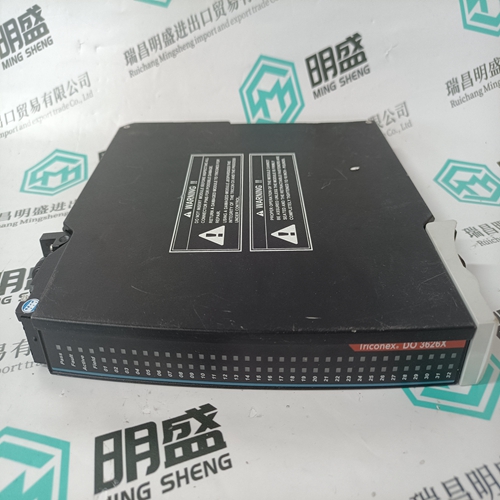

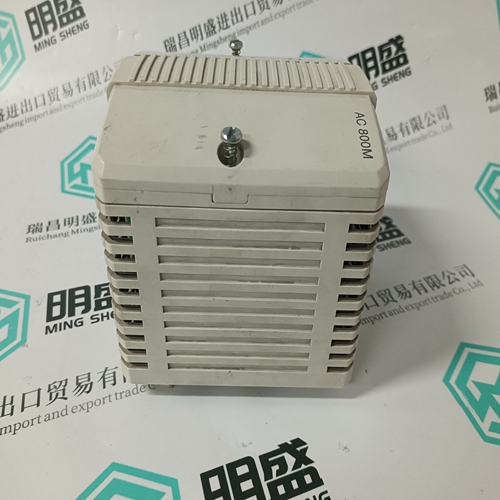

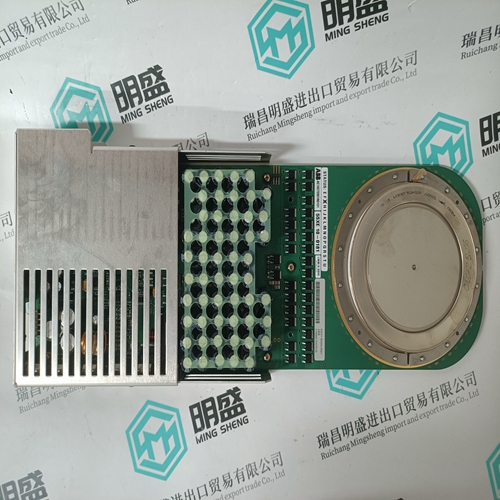

Product image

Related products:

Radisys ATCA-PP81 controller module

AMAT 0190-24282 encoder module

Other website links

More inventory models

| PP875 3BSE092977R1 | Gespac GESSIO-12 9921 GESPCB-436 | 3500/22 125768-01 |

| TRICONEX 4351B | GESPAC GESDMC-2 | 3500/32M 149986-02 |

| FM802 | ADC-12A GESADC-12A 9310 GESPCB-334 | 330180-51-05 |

| FM801 | GESPAC GESXT-11 GESXT11 | 330850-90-05 |

| FM803 | GESPAC GESDAC-1 GESDAC1 | 136188-01 |

| FM820 | Gespac GESCIO-1 8915 | 3500/45 176449-04 |

| FM821 | Gespac GESINP-2B 8720 | 330710-000-060-10-02-00 |

| UNS0881a-P,V1 3BHB006338R0001 | GESPAC GESDAC-2B 8945 | 125760-01 |

| RF533 3BSE014227R1 | GESPAC GESMDC-1 9520 | 330106-05-30-10-02-00 |

| NBRA-658C | Gespac GESTIM-1A TIM-1AC/24 | 3500/91-01-02-00 |