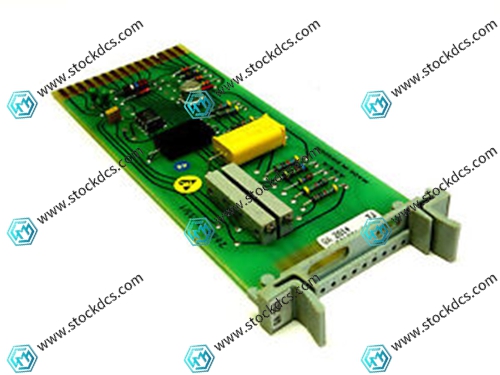

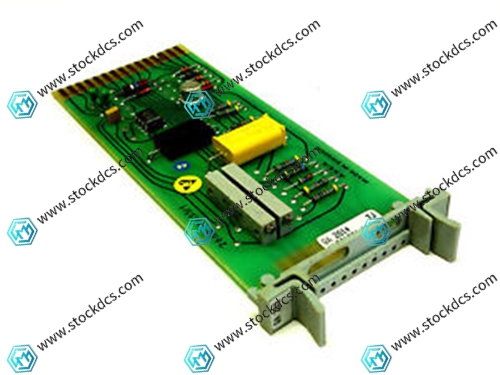

Home > Product > PLC programmable module > ASEA 2668 171-55 detector board

ASEA 2668 171-55 detector board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

ASEA 2668 171-55 detector board

Product Details Introduction

ASEA 2668 171-55 detector board is a critical component used in industrial automation and robotics systems. It is mainly used to detect and process signals from various sensors, supporting monitoring, control, and data processing functions of the system. The following is detailed information about the main features and application areas of the ASEA 2668 171-55 detector board.

Main features of ASEA 2668 171-55 detector board

Signal acquisition:

Designed to receive signals from various sensors, such as position sensors, speed sensors, force sensors, etc. Be able to accurately convert these signals into a format that the control system can understand.

high-precision:

Provide high-precision signal processing capabilities to ensure that the system can accurately detect and respond to various input signals, improving the overall performance of the system.

Real time feedback:

Support real-time data collection and feedback, able to monitor the status of sensors in real time, and make necessary adjustments and controls to the system.

Anti interference capability:

Has good resistance to electromagnetic interference and can operate stably in complex industrial environments, reducing the impact of interference on signals.

Modular design:

Modular design facilitates installation, maintenance, and replacement, seamlessly integrates with other modules and devices, and supports flexible system configuration.

compatibility:

Compatible with various ASEA (ABB) automation systems and robot control systems, supporting the needs of various automation applications.

application area

1. Industrial automation

Status monitoring: used for real-time monitoring of equipment and system status, receiving and processing sensor signals, and providing data for system control and optimization.

Fault detection: Monitor abnormal conditions of equipment, such as overload, faults, etc., provide alarm functions, support system fault diagnosis and maintenance.

2. Robot control

Motion feedback: Receive feedback signals from robot motion sensors, such as position, velocity, acceleration, etc., to support precise motion control and path planning.

Operation monitoring: Monitor the status of the robot during operation to ensure accuracy and safety of the operation.

3. Manufacturing industry

Production line inspection: used in the production line to monitor sensor signals, such as the status of conveyor belts and the operation of production equipment, to improve the automation level of the production line.

Quality control: Receive signals from quality inspection equipment, provide real-time quality monitoring and control, and ensure the high quality of products.

4. Automotive industry

Assembly line monitoring: used for sensor signal acquisition and processing on automotive assembly lines, such as status monitoring of assembly equipment, to ensure the accuracy and efficiency of the assembly process.

Performance testing: used for performance testing of automotive components, receiving feedback signals from testing equipment, supporting accurate testing and analysis.

5. Electronic industry

Production process monitoring: In the production process of electronic products, receiving and processing sensor signals, such as the position and status of components, supports high-precision manufacturing processes.

Equipment control: Monitor the operating status of electronic devices, provide real-time feedback and control, and ensure the normal operation of the equipment.

6. Food processing

Automated control: In food processing production lines, sensor signals are received to control automated equipment and systems, ensuring the stability and efficiency of the production process.

Fault alarm: Monitor the operating status of equipment, provide fault alarm function, and reduce production interruption and downtime.

overview

The ASEA 2668 171-55 detector board plays a critical role in industrial automation and robotics systems, supporting real-time monitoring and control of the system through high-precision signal acquisition and processing capabilities. It is widely used in fields such as industrial automation, robot control, manufacturing, automotive industry, electronics industry, and food processing.

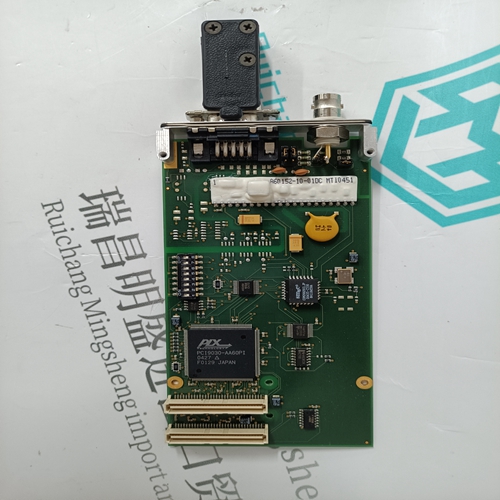

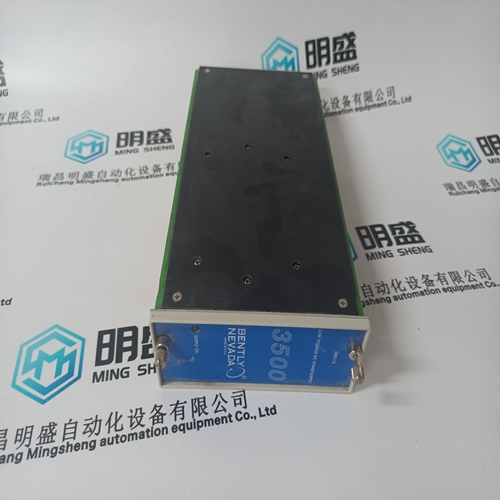

Product image

Related products:

AMAT 0190-66253 Communication Module

Other website links

More inventory models

| PMB33C-20101-00 | 70 AA 02a-E | N32HRFL-LNK-NS-00 |

| PMB31D-00116-02 | 70 AB 01b-E | N42HRFN-LNK-NS-00 |

| PMB31B-00214-00 | 70 AS 04b-E | N33HRHJ-LEK-M2-00 |

| PMB31D-10200-03 | 70 AS 06a-E | N43HCLL-LEK-M2-01 |

| PMB31B-00200-00 | 70 AS 32a-E | N33HCLG-LNK-NS-01 |

| PMB31B-00201-01 | 70 AS 40b-E | N31HRHJ-LNK-NS-00 |

| PMB31B-00114-01 | 70 AS 41b-E | N32HREM-LNK-NS-00 |

| PMB33E-10214-03 | 70 AS 45b-E | N32HRFM-LNK-NS-00 |

| PMB33F-10116-01 | 70 AS 46b-E | N31HRFJ-LNK-NS-00 |