Home > Product > Servo control system > ASEA DSQC223 Robot Control Board

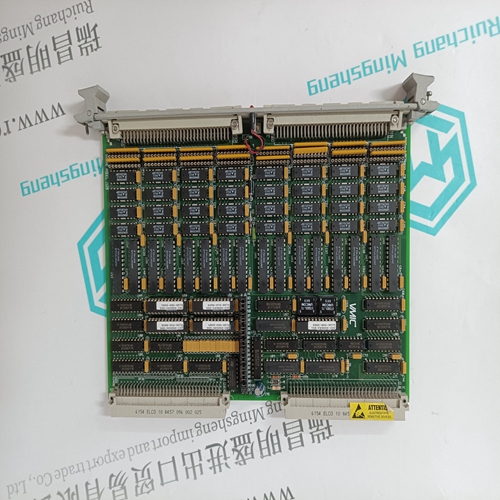

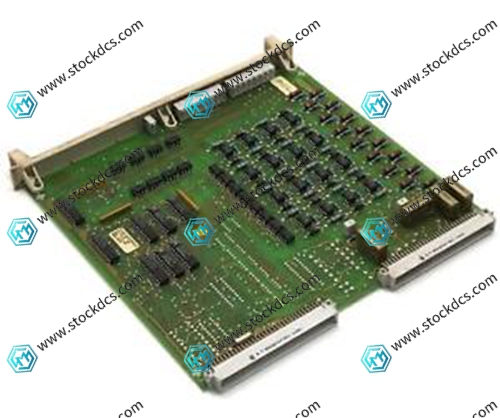

ASEA DSQC223 Robot Control Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

ASEA DSQC223 Robot Control Board

Product Details Introduction

The ASEA DSQC223 robot control board is an important component used in ASEA (now ABB) robot systems, mainly responsible for robot control and management. The following are the main features and application areas of the DSQC223 robot control board:

Main features of ASEA DSQC223 robot control board

Control function:

Motion Control: Responsible for the motion control of the robot arm, including the adjustment of position, velocity, and acceleration, to achieve precise actions and operations.

Path planning: Supports complex path planning and trajectory control to ensure that robots execute tasks according to predetermined paths.

High performance processing:

Real time processing: With real-time data processing capabilities, it can quickly respond to changes in the robot system, ensuring control accuracy and system stability.

High computing power: Built in high-performance processor capable of handling complex control algorithms and computational tasks.

Interface and Connection:

Multiple interfaces: Provides multiple input and output interfaces, supporting connections with sensors, actuators, and other control devices.

Communication Protocol: Supports multiple communication protocols for data exchange and control with other systems or devices.

System integration:

Compatibility: It is compatible with ASEA and other brands of robot systems and automation equipment, making it easy to integrate into existing systems.

Modular design: Designed as modular, it facilitates installation, maintenance, and replacement, improving the flexibility and reliability of the system.

Diagnosis and monitoring:

Fault diagnosis: With fault diagnosis function, it can monitor the system status in real time and provide fault information for easy maintenance and repair.

Real time monitoring: Supports real-time monitoring of the operating status of robot systems, providing data collection and performance analysis functions.

User friendly:

Operation interface: Designed with a user-friendly interface, it is easy to configure and adjust control parameters, simplifying the operation process.

application area

1. Industrial automation

Manufacturing: Used for various automation tasks in manufacturing, such as assembly, welding, spraying, etc., to improve production efficiency and product quality through precise control of robot movements.

Assembly line: On an automated assembly line, control robots to complete complex assembly tasks, improving assembly accuracy and speed.

2. Robot system

Motion control: In the robot system, DSQC223 is responsible for controlling the moving parts of the robot to achieve high-precision position and velocity control.

Complex tasks: Support the execution of complex robot tasks, such as multi axis coordinated motion, complex path tracking, etc.

3. Electronic industry

Testing and Assembly: Used for the testing and assembly process of electronic products, controlling robots for high-precision operation and testing.

Product handling: In electronic product production lines, controlling robots for product handling and classification improves production efficiency.

4. Manufacturing industry

Processing equipment: In CNC machine tools and other processing equipment, the DSQC223 control board is used for robot control to achieve precise processing operations.

Material handling: During the manufacturing process, control robots to handle and transport materials, supporting efficient production processes.

5. Medical and laboratory

Automated experiments: In medical and laboratory settings, controlling robots for automated experiments and sample processing improves experimental efficiency and accuracy.

Assembly and Handling: Used for the assembly and handling of medical equipment, providing high-precision operation and control.

overview

The ASEA DSQC223 robot control board plays a core role in various industrial automation and robot systems. Its high-performance processing capabilities, multiple interfaces and communication protocols, and advanced control functions enable it to meet complex robot control requirements.

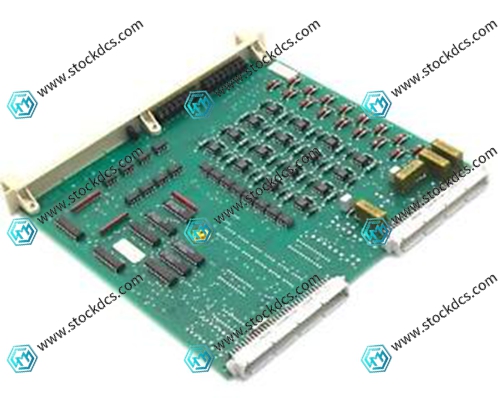

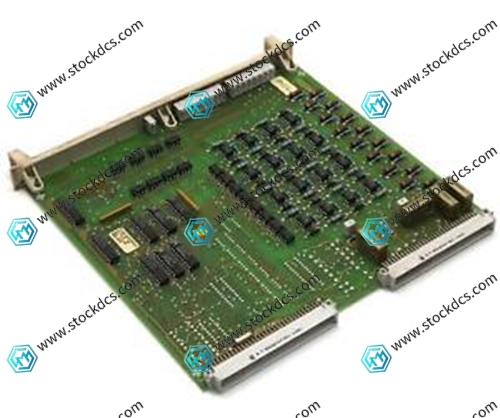

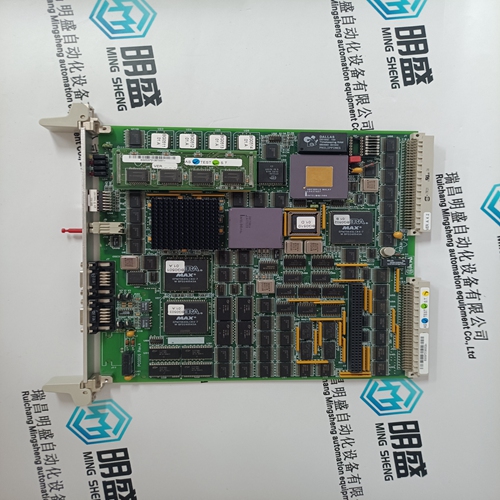

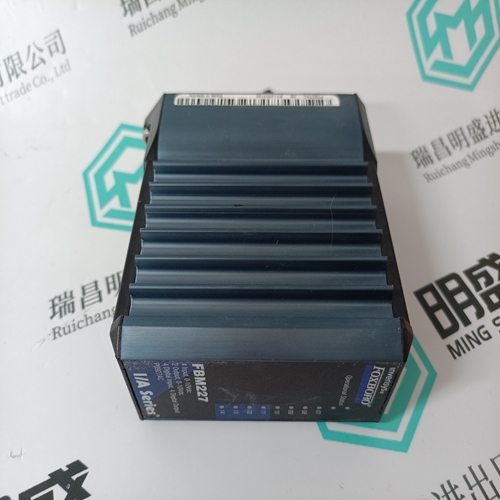

Product image

Related products:

IS400JPDHG1ABB IS410JPDHG1A Feedback Sen

RadiSys 61-0475-12 Axis Control Module

RADISYS 97-9536-20 Ethernet Port Module

Other website links

ABB REG670 1MRK002826-AC 安全系统组件

More inventory models

| VT-MAC8-13/K-AX4 | ICS TRIPLEX T8110B | MR-J3-200AN |

| VT-MSPA2-20/A5/000/000 R901439037 | ICS TRIPLEX T8153 | TRICONEX 8102 |

| FBM214 P0922VT | ICS TRIPLEX T8193 | TRICONEX 8306A |

| WDS-5000-P115-SR-I-VT | ICS TRIPLEX T8231 | TRICONEX 9000 |

| VT-MACAS-500-10/VO/I | ICS TRIPLEX T8310 | TRICONEX 9001 |

| VT3006S35R1 | ICS TRIPLEX T8402 | TRICONEX 8105 |

| VT-VPCD-1-16/V/0/1-0-1 | ICS TRIPLEX T8431 | TRICONEX 8106 |

| VT5041-25/1 | ICS TRIPLEX T8442 | TRICONEX 8302A |

| VT-VPCD-1-16/V0/1-P-1 | ICS TRIPLEX T8451 | TRICONEX 8300A |

| VT11013 | ICS TRIPLEX T8480 | TRICONEX 8301A . |