Home > Product > Servo control system > PACIFIC SCIENTIFIC SC904-001-01 Servo System

PACIFIC SCIENTIFIC SC904-001-01 Servo System

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

PACIFIC SCIENTIFIC SC904-001-01 Servo System

Product Details Introduction

The Pacific Scientific SC904-001-01 servo system is a high-performance servo drive system designed specifically for industrial automation and high-precision motion control applications. The following are the main features, technical specifications, and application areas of the servo system:

main features

High performance control

Provide precise motion control, supporting position, speed, and torque control modes.

Built in advanced control algorithms optimize the dynamic response and stability of servo motors.

quick response

High speed control circuits and fast response times are suitable for applications that require high dynamic performance.

Provide fast start stop and acceleration/deceleration capabilities to ensure efficient operation of the system.

high-precision

Support high-resolution encoders and feedback devices to achieve precise position and velocity control.

Low step error and jitter, providing smooth motion.

Compatibility and Scalability

Supports multiple communication protocols such as RS-232, RS-485, CANopen, EtherCAT, etc., making it easy to integrate with various control systems.

Provide rich I/O options and expansion modules to meet complex control requirements.

Protection function

It has multiple protection functions, including overcurrent, overvoltage, overtemperature, and short-circuit protection, to ensure the safety and reliability of the system.

user-friendliness

Equipped with easy-to-use configuration software, it simplifies the setup and debugging process.

Provide an intuitive user interface for easy monitoring and adjustment of system parameters.

high efficiency

Optimized power conversion efficiency, reduced energy consumption, and improved overall system efficiency.

technical specifications

Rated voltage: Specific parameters should refer to the product manual or supplier information.

Rated current: Specific parameters should refer to the product manual or supplier information.

Communication interfaces: RS-232, RS-485, CANopen, EtherCAT, etc.

Feedback device: Supports incremental encoders, absolute encoders, etc.

Maximum speed and torque: Specific parameters should refer to the product manual or supplier information.

application area

industrial automation

Used for robotic arms, conveyors, and automated production lines in factory automation systems, providing precise motion control to improve production efficiency and product quality.

numerical control machine

Used in CNC machine tools for feed axis and spindle control, achieving precision machining, providing high torque and high-speed control, ensuring machining quality and efficiency.

robotics

Used in robot systems to control the joint motion and path planning of robots, providing high precision and dynamic performance, ensuring the accuracy and flexibility of robot motion.

Packaging Machinery

Used for packaging, cutting, and labeling actions in packaging machinery, providing stable and fast motion control to improve packaging speed and accuracy.

Printing machinery

Used for paper conveying and alignment control in printing machinery, providing high-precision motion control to ensure printing quality and production speed.

Medical equipment

Used for precise positioning and motion in medical equipment, such as surgical robots and imaging devices, providing high reliability and precision to ensure the safety and accuracy of medical operations.

Example of usage scenarios

Automated production line: By controlling conveyor belts and robotic arms, efficient production and assembly can be achieved.

CNC machining center: controls the feed axis and spindle to achieve high-precision machining tasks.

Robot system: Control robot joints to achieve complex operational tasks.

Packaging and printing machinery: Control the movement of key components to improve packaging and printing efficiency.

The Pacific Scientific SC904-001-01 servo system is widely used in various industrial automation and motion control systems due to its high performance, precision, and reliability.

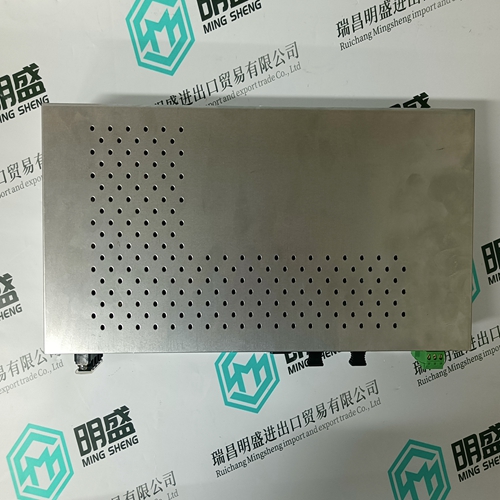

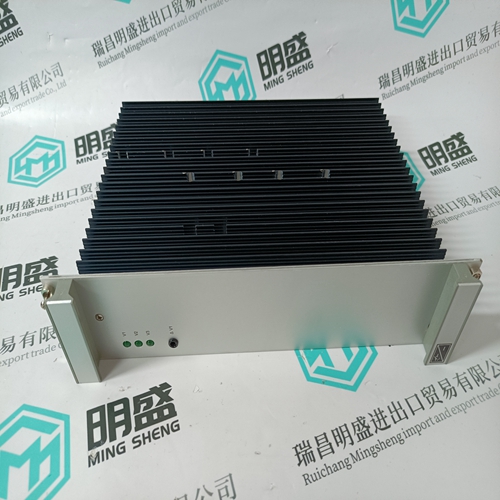

Product image

Related products:

ASEA 2668 184-447 Communication Module

ASEA DSQC100 connector backplane

Other website links

More inventory models

| PMB33E-10116-03 | 07AS82 | P21NRXB-LDN-PD-00 |

| PMB33C-10114-02 | 07BA60R1 | P21NRXB-LNS-NS-05 |

| PMB31D-20216-01 | 07BE60R1 | P22NSXA-LNN-NS-02 |

| PMB33F-10101-03 | 07BE62R1 | P22NSXA-LSS-SS-03 |

| PMB33C-10101-01 | 07BR60R1 | P21NSXS-LSS-NS-08 |

| PMB33F-10201-03 | 07BR61R1 | P21NRXD-LDN-NS-00 |

| PMB32D-00116-03 | 07BT60R1 | P22NSXA-LNF-NS-02 |

| PMB33E-10116-02 | 07BT62R1 | P22NSXC-LSN-NS-03 |

| PMB31D-10201-00 | 07BV60R1 | P22NRXB-LNN-NS-00 |

| PMB33F-00101-00 | 07CS61 | P21NSXC-LSN-NS-02 |

| PMB33F-10116-03 | 07EA200 | P21NSXS-LSS-NS-04 |